Mortar thickening powder and preparation method and application thereof

A thickening powder and mortar technology, applied in the field of mortar thickening powder, can solve the problems of wall looseness, cracking, hollowing, etc., and achieve the improvement of bonding strength and compressive strength, durability, workability and viscosity cohesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

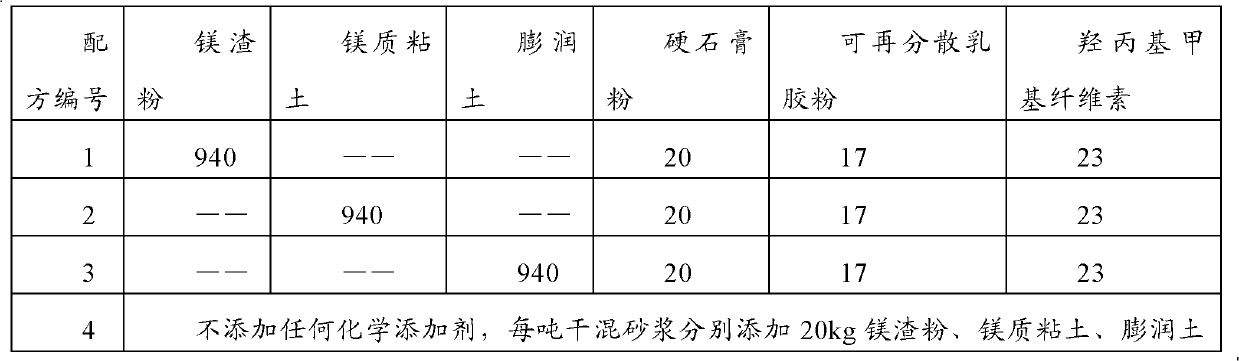

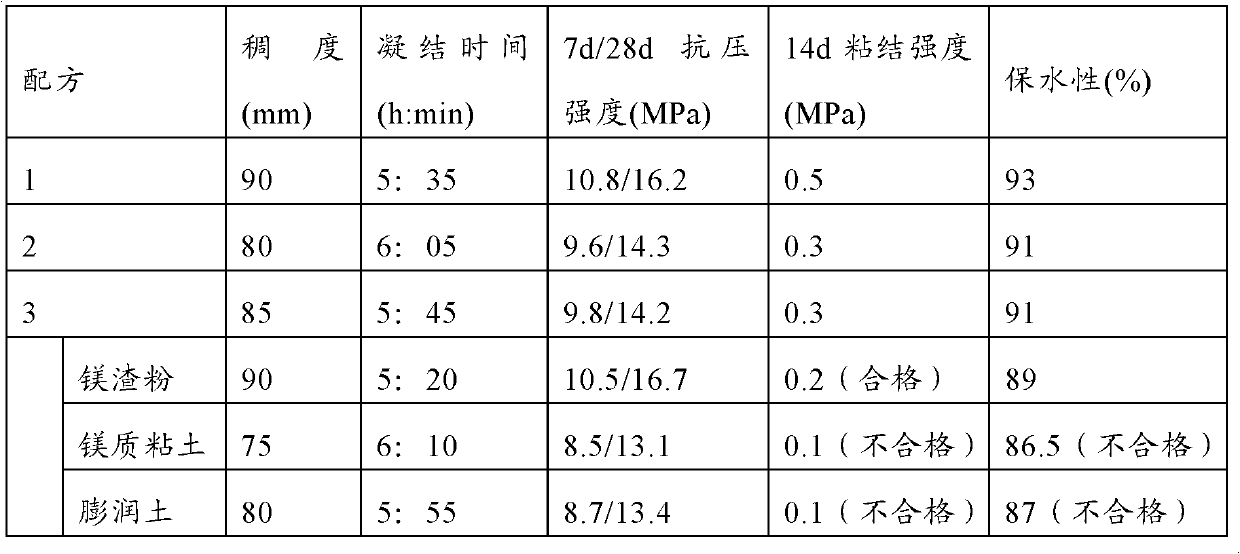

Examples

preparation example Construction

[0032] The preparation method of mortar thickening powder of the present invention is as follows:

[0033] Weigh each component according to the stated ratio, pour each component into a high-speed mixer in order of weight from large to small, and mix evenly. The mixing time is 5-10 minutes.

Embodiment 1

[0035] Weigh the following components: 92kg magnesium metal slag powder, 3.0kg anhydrite powder, 2.5kg redispersible latex powder, 2.5kg hydroxypropyl methylcellulose.

[0036] Put each raw material into the mixer in descending order of weight, and after mixing for 5 minutes, unload and pack.

Embodiment 2

[0038] Weigh the following components:

[0039] 93kg metal magnesium slag powder, 2.5kg anhydrite powder, 2.0kg redispersible latex powder, 2.5kg hydroxypropyl methylcellulose.

[0040] Put each raw material into the mixer in order of weight from large to small, mix for 10 minutes, and unpack for packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com