Formula for strong inhibitive high-density salt resistance drilling fluid capable of resisting temperature of 220 DEG C and preparation method of drilling liquid

A high-density, strong suppression technology, applied in the field of oil drilling drilling fluid, can solve the problems of difficult control of drilling fluid viscosity, large filtration loss, and low solid phase capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

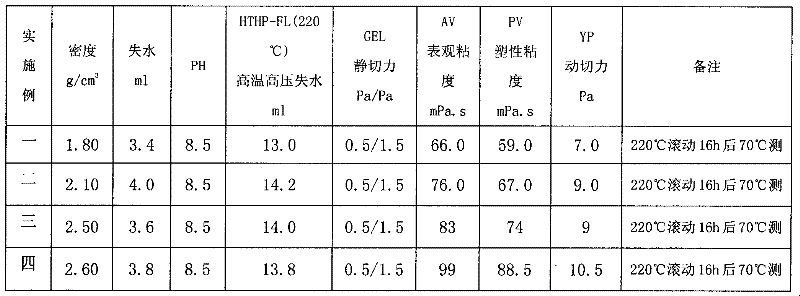

Examples

Embodiment 1

[0019] Embodiment one, according to the drilling fluid formula component 3kg / m 3 Soda ash, 30kg / m 3 High temperature anti-salt cutting agent, 0.5kg / m 3 Flow regulator, 26kg / m 3 Filtrate reducer A, 100kg / m 3 Filtrate reducer B, 110kg / m 3 Inhibiting anti-slump agent, 80kg / m 3 Inhibit lubricant, 1000kg / m 3 Strong inhibition of high density water-soluble weighting agent, 525kg / m 3 Inert weighting agent, each specific component is selected from the components described in the previous technical scheme, wherein the inert weighting agent is barite BaSO 4 ;

[0020] The preparation method of embodiment one, according to the component of above-mentioned drilling fluid formula, take the following steps:

[0021] (1) Measure and calculate the amount of fresh water required to prepare the drilling fluid, at a stirring speed of 12000 rpm, press 3kg / m in fresh water 3 The concentration of soda ash is added, stirred for 10 minutes, and then press 30kg / m 3 Add the high-temperature a...

Embodiment 2

[0027] Embodiment two, according to drilling fluid formula component 3kg / m 3 Soda ash, 30kg / m 3 High temperature anti-salt cutting agent, 0.5kg / m 3Flow regulator, 26kg / m 3 Filtrate reducer A, 100kg / m 3 Filtrate reducer B, 110kg / m 3 Inhibiting anti-slump agent, 80kg / m 3 Inhibit lubricant, 1000kg / m 3 Strong suppression high density water-soluble weighting agent, 1200kg / m 3 Inert weighting agent, each component is selected from the components described in the previous technical scheme, wherein the inert weighting agent is selected from barite BaSO 4 ;

[0028] The preparation method of embodiment two, according to the component of above-mentioned drilling fluid formula, take the following steps:

[0029] (1) Measure and calculate the amount of fresh water required to prepare the drilling fluid, at a stirring speed of 12000 rpm, press 3kg / m in fresh water 3 The concentration of soda ash is added, stirred for 10 minutes, and then press 30kg / m 3 Add the high-temperature an...

Embodiment 3

[0035] Embodiment three, according to drilling fluid formula component 3kg / m 3 Soda ash, 30kg / m 3 High temperature anti-salt cutting agent, 0.5kg / m 3 Flow regulator, 26kg / m 3 Filtrate reducer A, 100kg / m 3 Filtrate reducer B, 110kg / m 3 Inhibiting anti-slump agent, 80kg / m 3 Inhibit lubricant, 1000kg / m 3 Strong inhibition of high density water-soluble weighting agent, 2470kg / m 3 Inert weighting agent, each component is selected from the components described in the previous technical scheme, wherein the inert weighting agent is selected from barite ilmenite powder;

[0036] The preparation method of embodiment three, according to the component of above-mentioned drilling fluid formula, take the following steps:

[0037] (1) Measure and calculate the amount of fresh water required to prepare the drilling fluid, at a stirring speed of 12000 rpm, press 3kg / m in fresh water 3 The concentration of soda ash is added, stirred for 10 minutes, and then press 30kg / m 3 Add the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com