Semiconductor radiation sensing device and manufacturing method thereof

A radiation-sensitive, semi-conductive technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of high lower limit of energy detection and low energy resolution, so as to improve energy resolution, reduce response time, The effect of reducing the lower limit of energy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

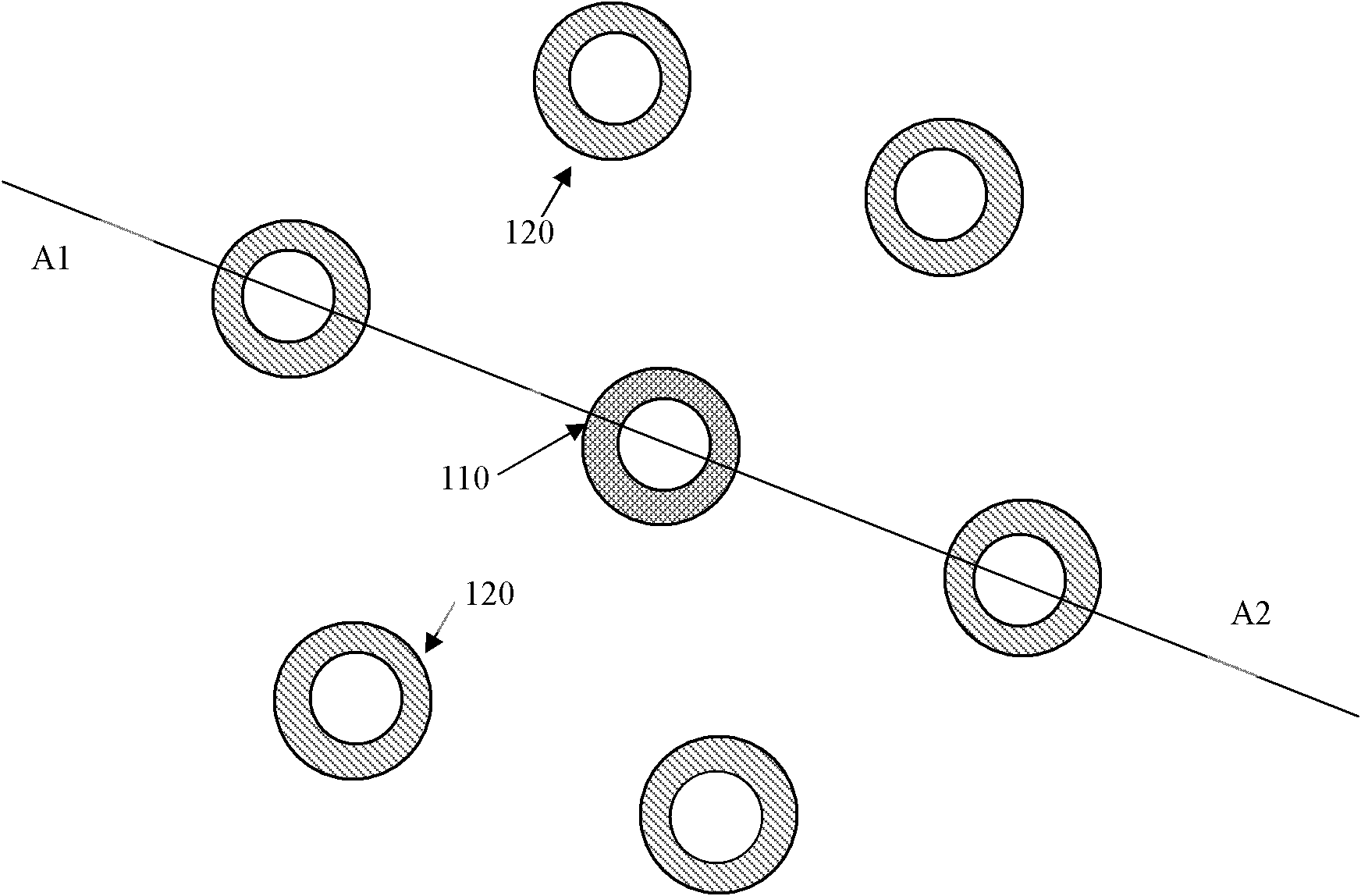

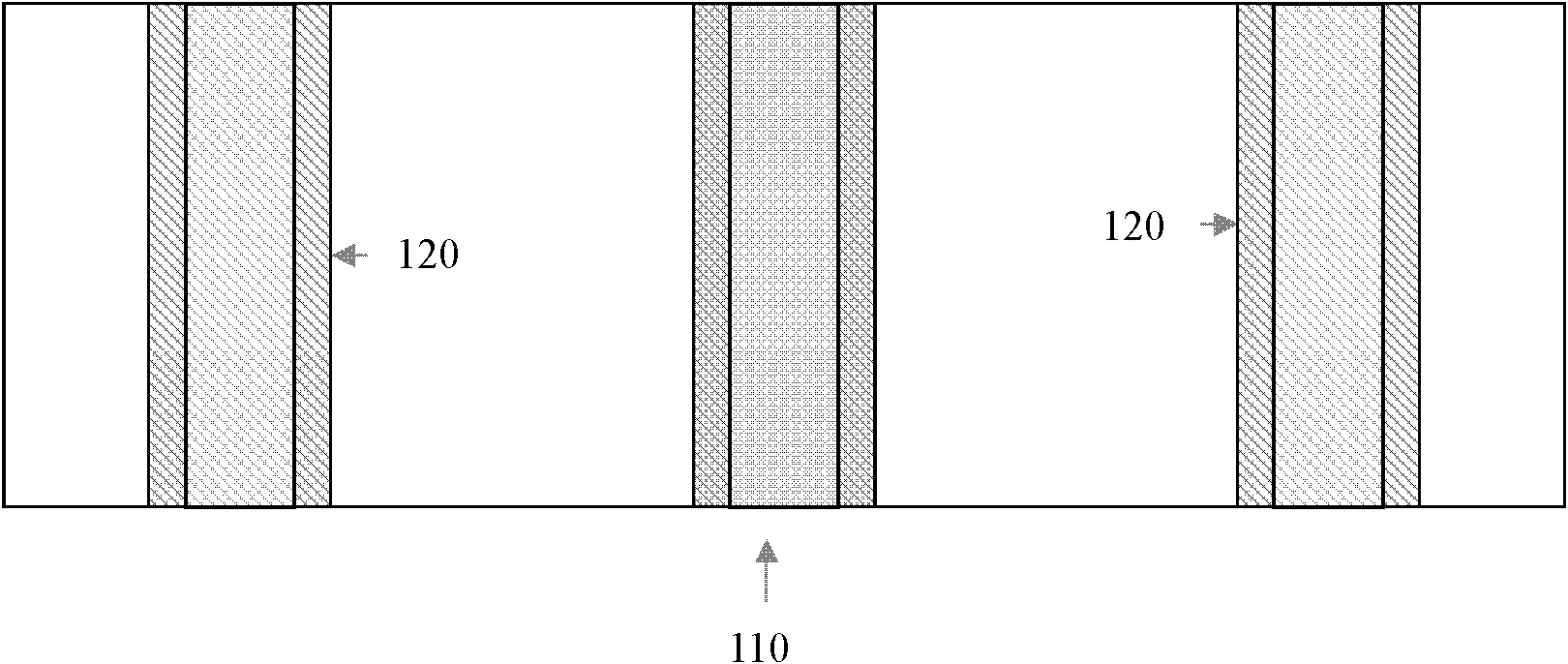

[0039] Figure 1~ Figure 5 As shown, the present invention provides a semiconductor radiation sensitive device, which contains at least one radiation sensitive unit. As shown in FIG. 1 , the radiation sensitive unit includes: a first substrate 100 , a first columnar electrode 110 , and a second columnar electrode 120 .

[0040] The first substrate 100 contains a first surface and a second surface;

[0041] The first columnar electrode 110 includes a first metal column 113 and N-type doped silicon 112 surrounding the first metal column;

[0042] The second columnar electrode 120 includes a second metal column 123 and a P-type doped silicon 122 surrounding the second metal column;

[0043] The first columnar electrode 110 and the second columnar electrode 120 are embedded inside the first substrate, vertically penetrating through the first surface and the second surface of the substrate;

[0044] The second columnar electrode 120 contains 6 metal columns arranged in a regular...

Embodiment 2

[0050] Figure 1~ Figure 5 As shown, the present invention provides a semiconductor radiation sensitive device, which includes at least one radiation sensitive unit and a signal processing circuit of the radiation sensitive unit, and the signal processing circuit is prior art. Radiation sensitive units such as Figure 5 As shown, it includes: a first substrate 100 , a first columnar electrode 110 , a second columnar electrode 120 , first pads 114 and 124 , and a second substrate 200 .

[0051] The structures of the first base body 100 , the first columnar electrode 110 , and the second columnar electrode 120 are the same as those in the first embodiment.

[0052] The first pad 114 is located at one end of the first columnar electrode 110 , and the first pad 124 is located at one end of the second columnar electrode 120 ;

[0053]The second substrate 200 is located on the first substrate 100;

[0054] The second substrate 200 contains a signal processing circuit and a second...

Embodiment 3

[0057] Figure 1~ Figure 5 As shown, the present invention provides a new manufacturing method designed for the above-mentioned semiconductor radiation sensitive device, comprising steps:

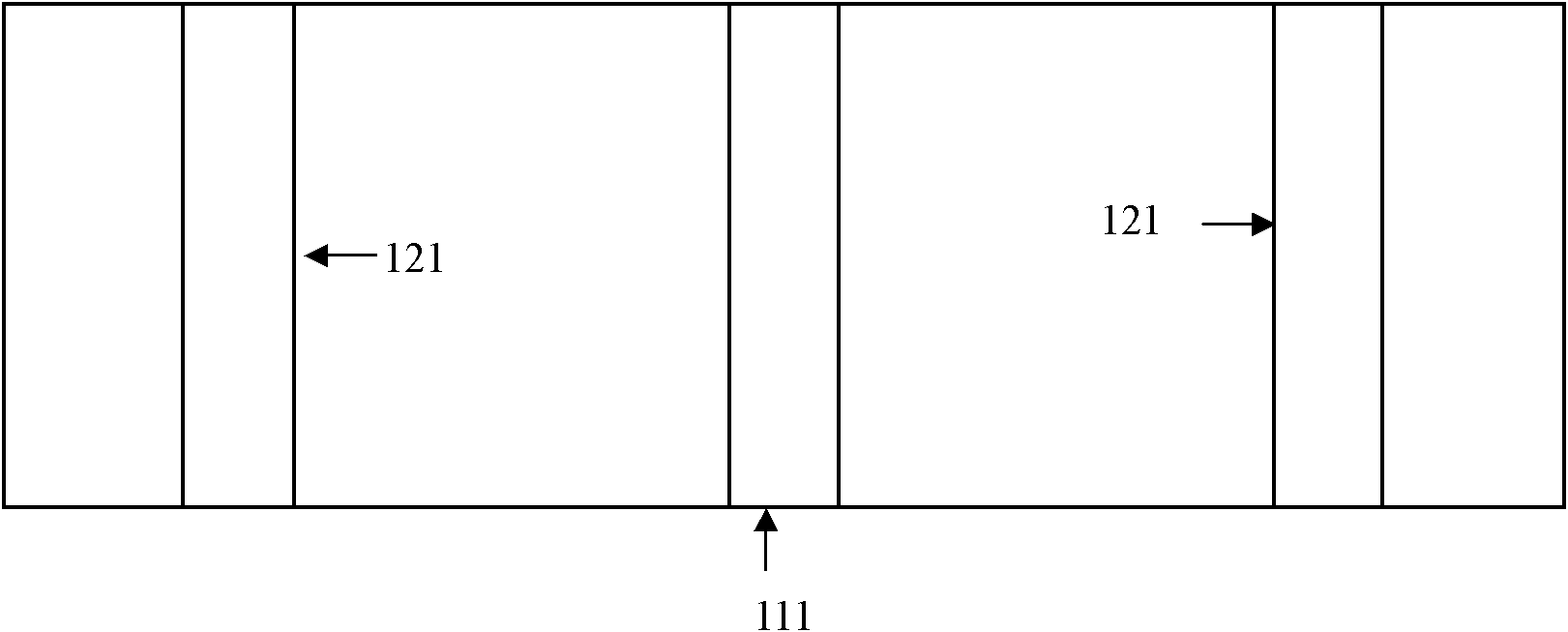

[0058] S1. A first wafer 100 is provided, and a first TSV through-silicon via 111 and a second TSV through-silicon via 121 are fabricated on the wafer, such as figure 2 shown. The fabrication of TSV through-silicon vias is as follows: coating photoresist, photolithography exposure, and development to make TSV through-silicon via mask; deep reactive ion (DRIE) etching through the silicon wafer to remove the photoresist. TSV through-silicon vias are also produced by double-sided photolithography and double-sided engraved holes; other methods, such as laser drilling, can also be used.

[0059] S2. Fabricate a first columnar electrode 110 and a second columnar electrode 120 in the TSVs 111 and 121 of the first wafer, respectively, as shown in FIG. 3 . The columnar electrodes are made in det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com