Preparation technology and method for natural food anti-oxidant containing bamboo vinegar liquid

A food antioxidant and anti-oxidant technology, which is applied in food preservation, food science, application, etc., can solve the problems of insufficient research and achieve the effect of improving anti-oxidation and non-toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

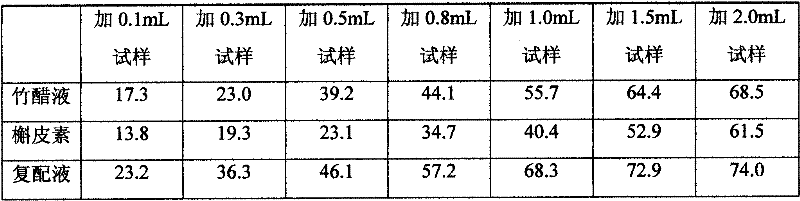

[0023] Scavenging of DPPH free radicals

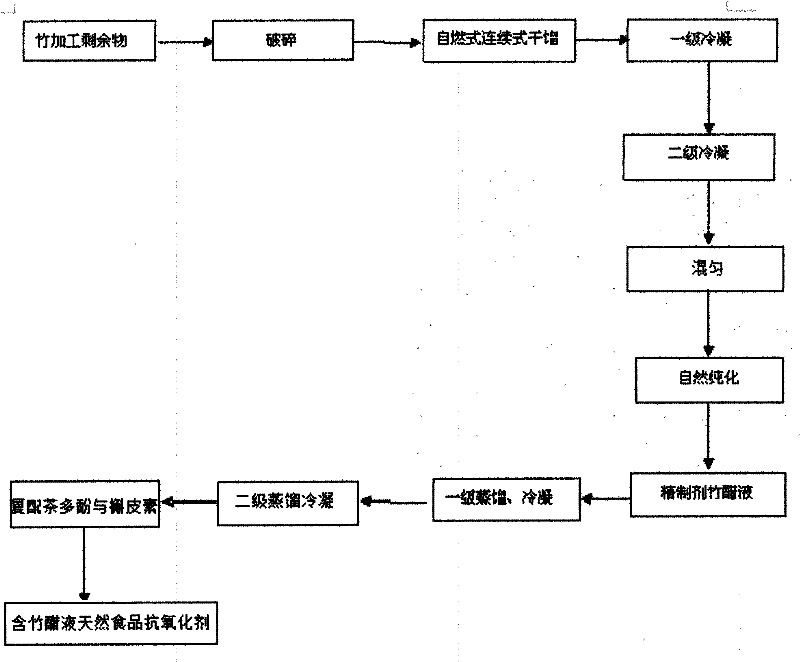

[0024] Preparation of refined bamboo vinegar: slice the unpolluted bamboo processing residues using a disc-type bamboo crusher (extruded and cut), and the size of the bamboo slices is 4-6cm×4-6cm, and then put them in Jiangyin Torch Biotechnology Co., Ltd. (2010-1 type) bamboo wood vinegar extraction and purification equipment → spontaneous combustion continuous dry distillation, carbonization (under normal pressure, the temperature is controlled in the range of 300°C-500°C) → primary condensation (temperature is controlled at 100°C-120°C interval to obtain bamboo vinegar liquid) → secondary condensation (control the temperature between 110°C-130°C to obtain bamboo vinegar liquid) → mixing tank (mix the primary and secondary condensate under normal temperature and pressure) → leave standstill, carry out purification (180 days) → obtain refining bamboo vinegar liquid under natural state.

[0025]Preparation of bamboo vinegar liquid for...

Embodiment 2

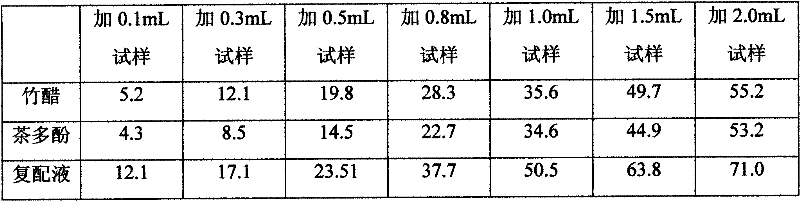

[0031] to superoxide anion radical O 2 · - the removal of

[0032] Preparation of refined bamboo vinegar: slice the unpolluted bamboo processing residues using a disc-type bamboo crusher (extruded and cut), and the size of the bamboo slices is 4-6cm×4-6cm, and then put them in Jiangyin Torch Biotechnology Co., Ltd. (2010-1 type) bamboo wood vinegar extraction and purification equipment → spontaneous combustion continuous dry distillation, carbonization (under normal pressure, the temperature is controlled in the range of 300°C-500°C) → primary condensation (temperature is controlled at 100°C-120°C interval to obtain bamboo vinegar liquid) → secondary condensation (control the temperature between 110°C-130°C to obtain bamboo vinegar liquid) → mixing tank (mix the primary and secondary condensate under normal temperature and pressure) → leave standstill, carry out purification (180 days) → obtain refining bamboo vinegar liquid under natural state.

[0033] Preparation of bamb...

Embodiment 3

[0039] Scavenging of hydroxyl radical·OH

[0040] Preparation of refined bamboo vinegar: slice the unpolluted bamboo processing residues using a disc-type bamboo crusher (extruded and cut), and the size of the bamboo slices is 4-6cm×4-6cm, and then put them in Jiangyin Torch Biotechnology Co., Ltd. (2010-1 type) bamboo wood vinegar extraction and purification equipment → spontaneous combustion continuous dry distillation, carbonization (under normal pressure, the temperature is controlled in the range of 300°C-500°C) → primary condensation (temperature is controlled at 100°C-120°C interval to obtain bamboo vinegar liquid) → secondary condensation (control the temperature between 110°C-130°C to obtain bamboo vinegar liquid) → mixing tank (mix the primary and secondary condensate under normal temperature and pressure) → leave standstill, carry out purification (180 days) → obtain refining bamboo vinegar liquid under natural state.

[0041] Preparation of bamboo vinegar liquid f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com