Zirconia or alumina hollow ball grading machine and method for grading hollow balls

A technology of alumina hollow spheres and zirconia, applied in chemical instruments and methods, solid separation, classification, etc., can solve the problem that functions and effects cannot meet the requirements of non-metallic material hollow spheres, and there is no sorting of zirconia or alumina Problems such as spheroids, waste of human resources and material resources, etc., achieve the effect of optimizing the allocation of human resources, separating specifications and standards, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

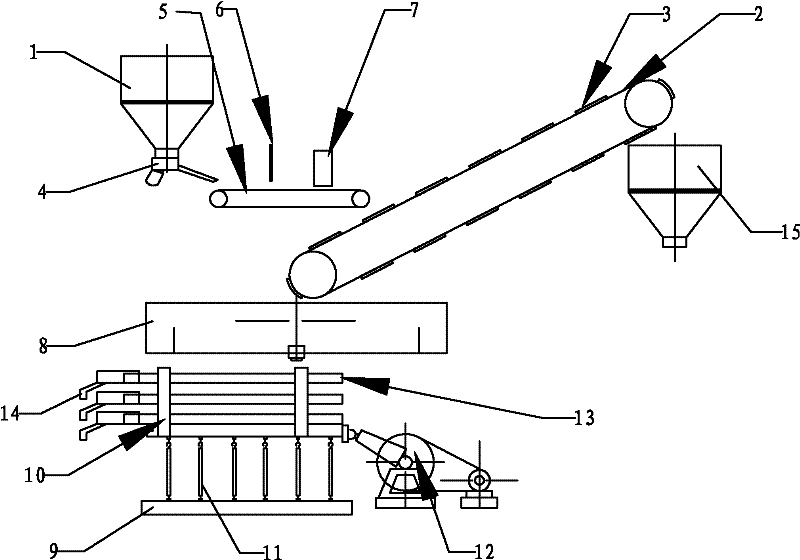

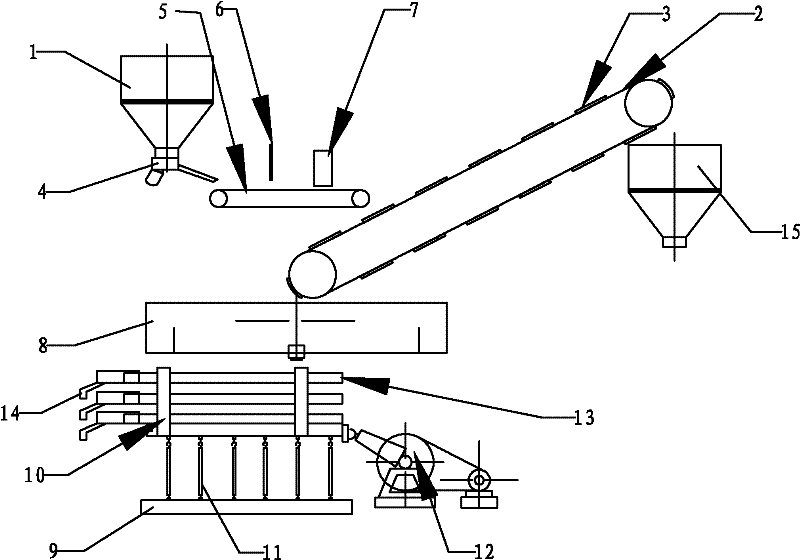

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0023] With reference to accompanying drawing, what shown in the accompanying drawing is a kind of zirconia or aluminum oxide hollow ball sorting machine provided by the present invention, comprise storage bin 1 of unseparated mixture, feeding device for conveying mixture, sphere separating device, all The sphere separating device is a sorting conveyor belt 2 whose conveying direction is inclined from bottom to top, and the sorting conveyor belt 2 has a rough surface.

[0024] The present invention cleverly arranges a sorting conveyor belt 2 with a conveying direction from bottom to top after the feeding device. The surface of the sorting conveyor belt 2 is rough, which greatly increases the sliding friction force, but the rolling friction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com