Method and system for adjusting temperature of extruding and casting pressure chamber

A technology of squeeze casting and adjustment method, which is applied in the field of squeeze casting equipment, can solve the problems affecting the cooperation between the pressure chamber and the punch, the temperature fluctuation of the injection system, and the reduction of the service life of the pressure chamber, so as to reduce the difference of thermal deformation and Effects of thermal stress, avoiding excessive friction and wear, and reducing chances of heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described through the following examples in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

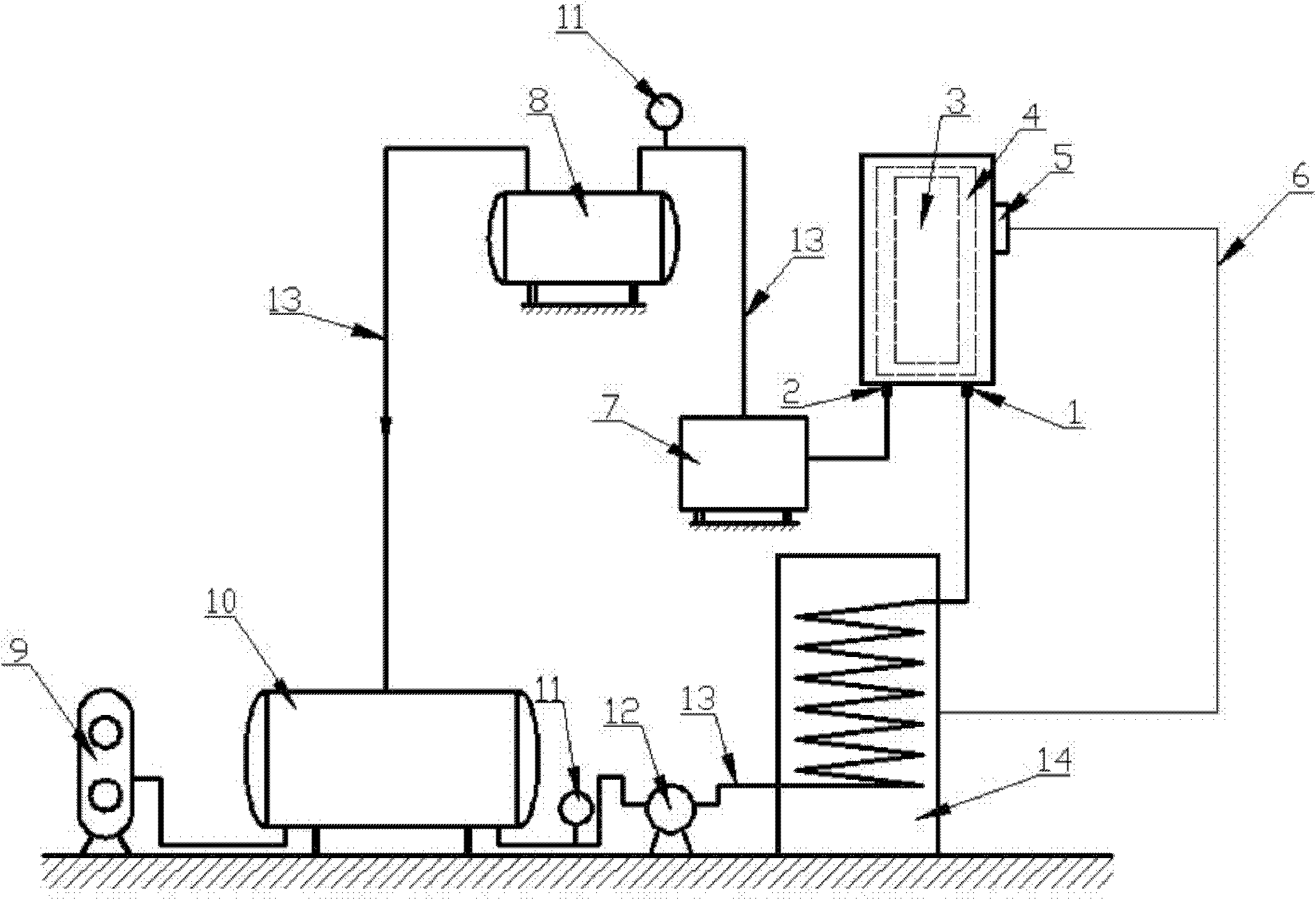

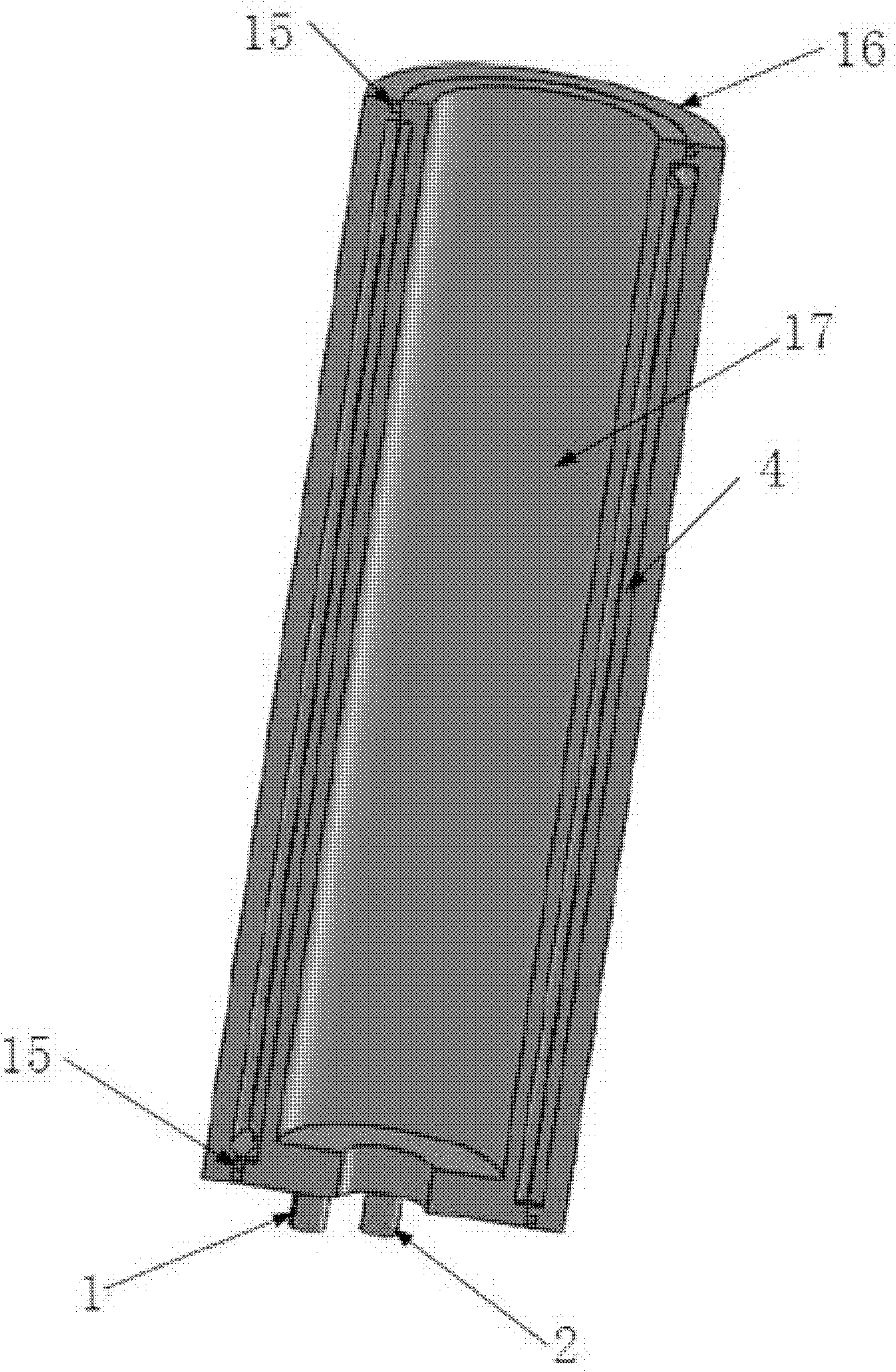

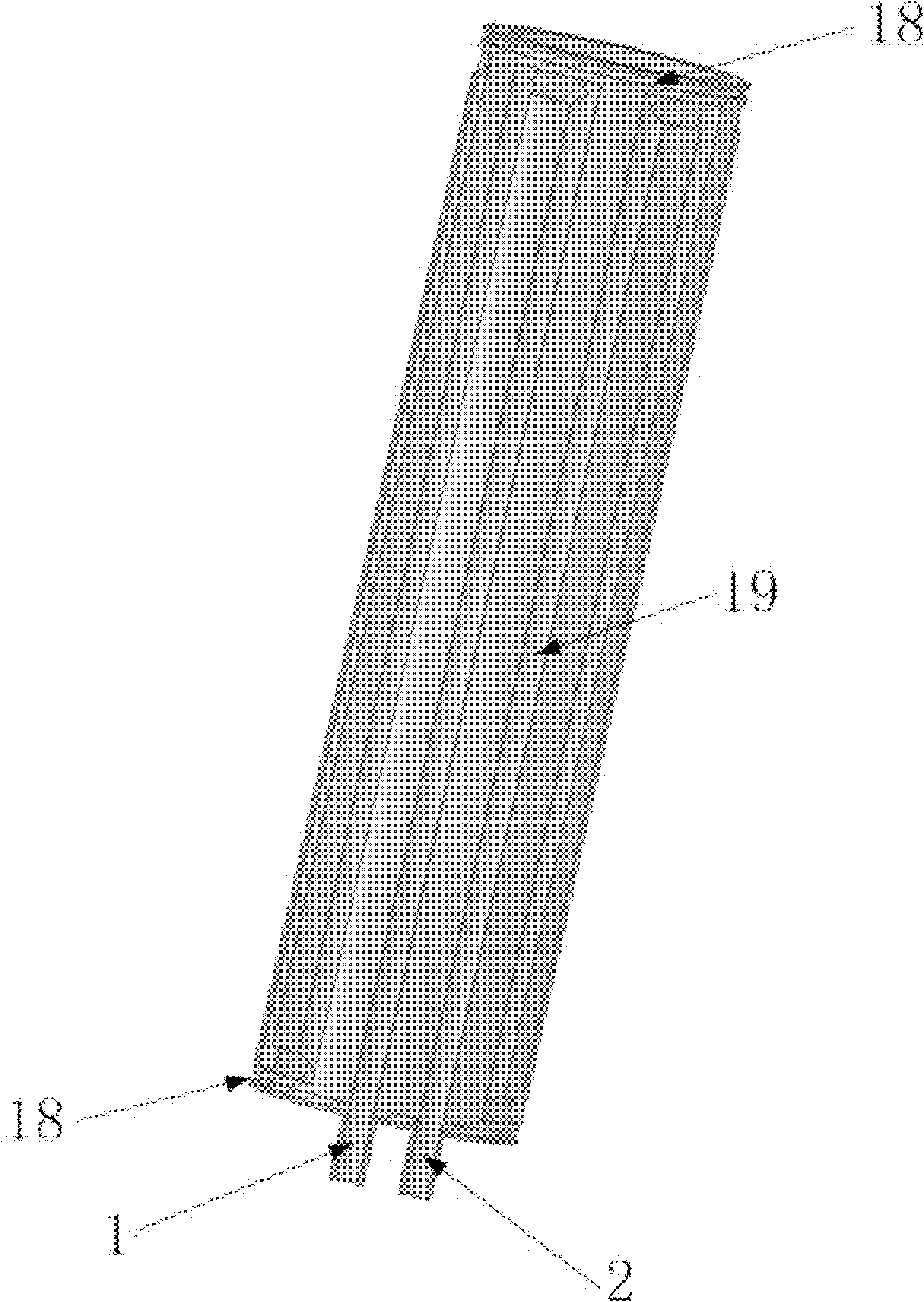

[0030] Such as figure 1 Shown is a squeeze casting pressure chamber temperature adjustment system including a squeeze casting pressure chamber 3, which consists of an oil inlet 1, an oil outlet 2, a heat transfer oil channel 4, a temperature detection device 5, a signal transmission line 6, a filter Oiler 7, expansion tank 8, oil injection pump 9, oil storage tank 10, oil pressure gauge 11, circulation pump 12, oil delivery pipe 13 and heat exchange device 14. Such as figure 2 As shown, the squeeze casting pressure chamber 3 is assembled from two parts, the outer casing wall 16 and the inner casing wall 17, and the inner wall of the outer casing wall 16 and the outer wall of the inner casing wall 17 are respectively provided with heat transfer oil flow grooves 19 correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com