Method for preparing near-zero thermal expansion composite material

A composite material and near-zero expansion technology, which is applied in the field of methods and near-zero thermal expansion composite materials, and the preparation of near-zero thermal expansion composite materials, can solve the problems of high thermal expansion coefficient and strong thermal stress of composite materials, and achieve the effect of low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this embodiment, y=0 and x=0 in the general formula (I) are taken, that is, the general formula of the precursor is ZrW 2 o 7 (OH) 2 2H 2 O.

[0057] According to the ratio of stoichiometric ratio Zr:W=1:2, weigh 0.04mol5(NH 4 ) 2 O·12WO 3 ·5H 2 O and 0.02mol ZrOCl 2 ·8H 2 O, respectively dissolved in 40mL of distilled water, while stirring, the two solutions were dropped into 30mL of distilled water at the same time, resulting in a white precipitate. After the dropwise addition was completed, stirring was continued for 2 h to obtain a white slurry. While stirring, the white slurry was heated and evaporated to dryness to obtain a white solid.

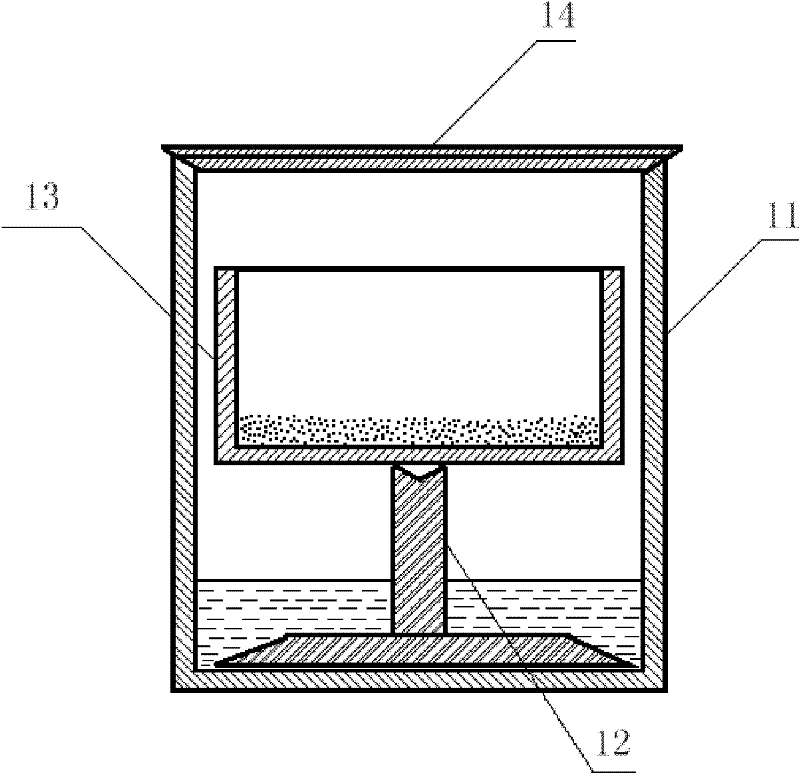

[0058] After taking the white solid and grinding it, put it into figure 1 In the second container shown, add 10 mL of hydrochloric acid with a concentration of 6 mol / L into the first container as an acid gas source, place the second container in the first container above the liquid level, seal it, and place it togethe...

Embodiment 2

[0070] Raw material adopts 5 (NH 4 ) 2 O·12WO 3 ·5H 2 O, (NH 4 ) 6 Mo 7 o 24 4H 2 O and ZrOCl 2 ·8H 2 O, mixed according to the stoichiometric ratio, and then prepared according to the method of Example 1 to obtain the zirconium tungstomolybdate precursor ZrWMoO 7 (OH) 2 (H 2 O) 2 . The concentration of W, Zr and Mo elements in the gas source solution after the reaction is detected by ICP method, and the calculation results show that the amounts of W, Zr and Mo elements lost in the gas source solution are all less than 0.02wt%.

[0071] Take PbO powder, B 2 o 3 Powder and SiO 2 After the powder and the precursor are mixed according to the ratio in Table 1, take 0.5g of the mixture and put it into a stainless steel mold for compression molding to obtain a molded body. The inner wall of the stainless steel mold is coated with a lubricant as a release agent in advance, and the molding pressure is 3.2 MPa.

[0072] The molded body was fired at 510°C for 8h in the...

Embodiment 3

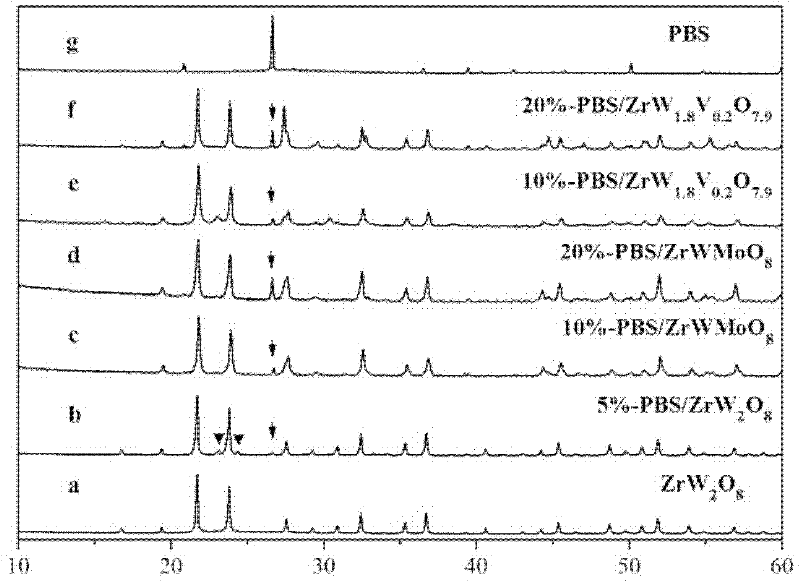

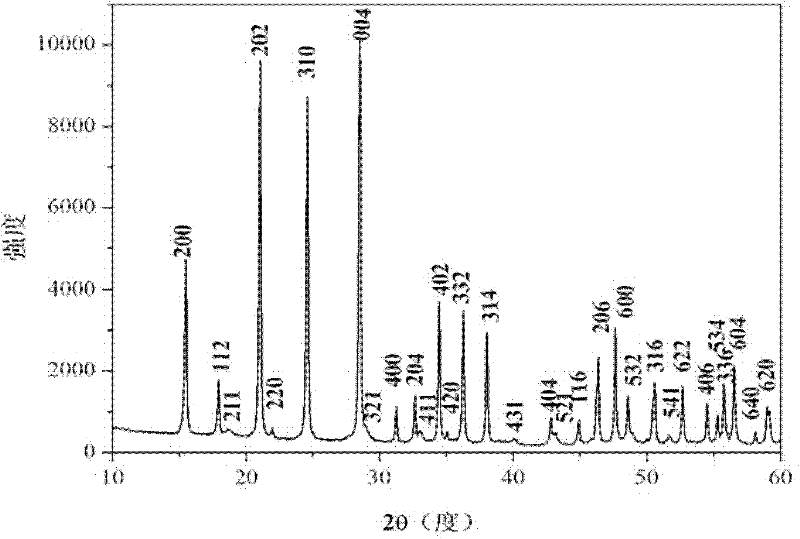

[0078] The raw material is 0.01mol ZrOCl 2 ·8H 2 O, 0.01×1.8 / 12mol5(NH 4 ) 2 O·12WO 3 ·5H 2 O, 0.01×0.2mol NH 4 VO 3 After mixing, then prepare zirconium tungstate precursor ZrW according to the method for embodiment 1 1.8 V 0.2 o 6.9 (OH) 2 h 2 O, measure the XRD pattern such as image 3 shown. image 3 The results show that the diffraction index of the precursor body conforms to the I4 1 Diffraction conditions of the cd space group, the crystal and ZrMo 2 o 7 (OH) 2 (H 2 O) 2 (Clearfield, A.; Blessing, R.H., The preparation of a crystalline basic zirconium tungstate. J. Inorg. Nuc. Chem. 1974, 36(5), 1174-1176) is a heteroisomeric compound.

[0079] Take PbO powder, B 2 o 3 Powder and SiO 2 After mixing the powder and the precursor according to the ratio in Table 1, take 0.5 g of the mixture and put it into a stainless steel mold for compression molding to obtain a molded body. The inner wall of the stainless steel mold is coated with a lubricant as a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average linear expansion coefficient | aaaaa | aaaaa |

| Average linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com