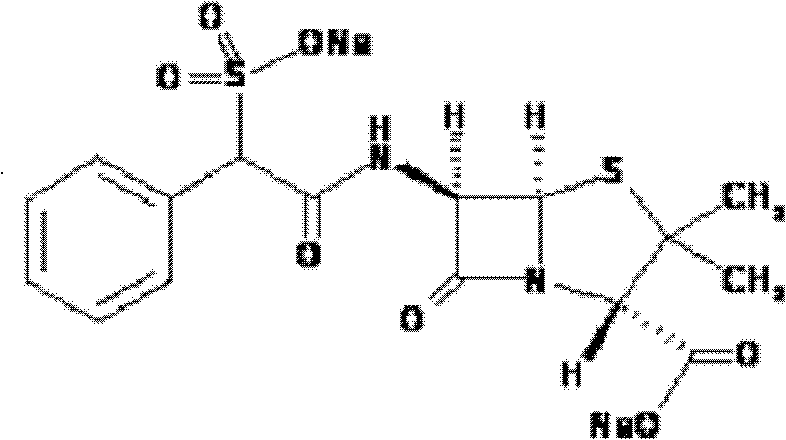

Method for purifying D (-)-sulbenicillin sodium

A technology of sulfbenicillin sodium and its purification method, which is applied in the field of purifying D-sulfbenicillin sodium with β-cyclodextrin, can solve the problems of easy racemization of the L-isomer, complex process, high equipment cost, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (a) the crude product of sulbenicillin sodium and water are mixed and dissolved in a weight ratio of 2:1;

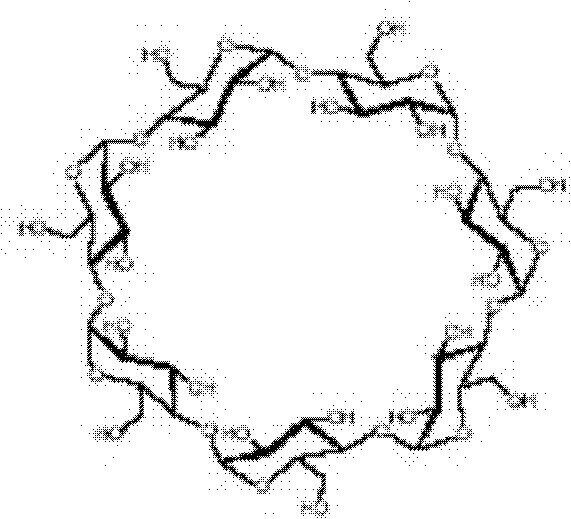

[0054] (b) The temperature of the solution is kept at 30°C and passed through a porous ceramic tube with a β-cyclodextrin membrane with a pore size of 60 μm, and the solution flow rate is 6dl / sec;

[0055] (c) Add dehydrated ethanol of 1 / 2 weight of the crude product of sulbenicillin sodium and isopropanol of the weight of the crude product of sulbenicillin sodium, stir and grow crystals in the reaction tank until a large amount of crystals are precipitated, and turn on the frozen brine to cool down for 8 hours;

[0056] (d) Centrifugal separation to obtain D(-)-sulfbenicillin sodium.

[0057] The yield of sulbenicillin sodium is 60%, wherein the content of D(-)-sulbenicillin sodium is 80%. The measured optical rotation of the product is [α]D: +160°~+180°.

Embodiment 2

[0059] (a) the crude product of sulbenicillin sodium is mixed with water in a weight ratio of 9: 1;

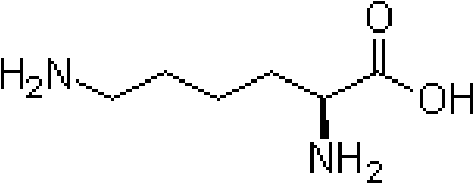

[0060] (b) A ceramic tube with a pore size of 2 μm passing through a loaded L-lysine-β-cyclodextrin membrane at room temperature, and a solution flow rate of 2 dl / sec;

[0061] (c) Add dehydrated alcohol of 1 / 2 weight of the crude product of sulbenicillin sodium and isopropanol of the weight of the crude product of sulbenicillin sodium, stir and grow crystals in the reaction tank until a large amount of crystals are precipitated, and turn on the frozen brine to cool down for 9 hours;

[0062] (d) Centrifugal separation to obtain D(-)-sulfbenicillin sodium.

[0063] The yield of sulbenicillin sodium is 65%, wherein the content of D(-)-sulbenicillin sodium is 99%. The measured optical rotation of the product is [α]D: +175°~+180°.

[0064] NMR test results of the obtained product: 1H-NRM (400MHz, D2O) δ (ppm): 1.4025 (t, 6H, -CH3), 4.1153 (d, H, -CH-COONa), 4.9275 (s, H, Ar- C...

Embodiment 3

[0066] (a) the crude product of sulbenicillin sodium is mixed with water in a weight ratio of 7: 1;

[0067] (b) Keep the solution temperature at 27°C and pass through a ceramic tube loaded with carboxymethyl-β-cyclodextrin membrane with a pore size of 100 μm, and the solution flow rate is 10dl / sec;

[0068] (c) Add dehydrated ethanol of 1 / 2 weight of the crude product of sulbenicillin sodium and isopropanol of the weight of the crude product of sulbenicillin sodium, stir and grow crystals in the reaction tank until a large amount of crystals are precipitated, and turn on the frozen brine to cool down for 10 hours;

[0069] (d) Centrifugal separation to obtain D(-)-sulfbenicillin sodium.

[0070] The yield of sulbenicillin sodium is 50%, wherein the content of D(-)-sulbenicillin sodium is 93%. The measured optical rotation of the product is [α]D: +170°~+180°.

[0071] It can be seen from the above that the product obtained in Example 2 has the narrowest range of optical rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com