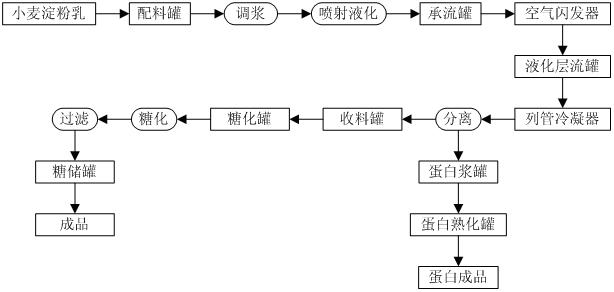

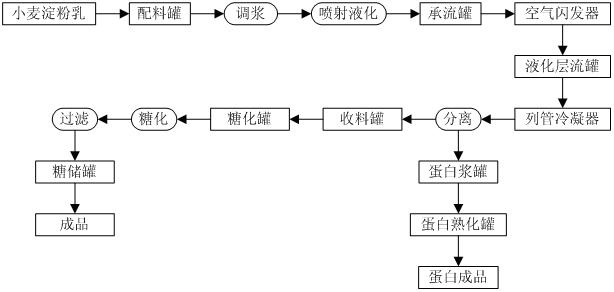

Biological sugaring process by using wheat starch

A wheat starch and biological technology, applied in the direction of fermentation, can solve the problems of long saccharification time, low conversion rate, and more wheat protein, and achieve the effects of less complex saccharification reaction, short saccharification cycle, and improved light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0023] 1. Mixing

[0024] 1.1. Check whether the bottom valve and drain valve of the batching tank are closed, and whether the mixing equipment is operating normally.

[0025] 1.2. After receiving the instruction to make starch milk from the starch workshop, open the starch milk feed valve of the batching tank to receive wheat starch milk (preferably wheat A starch powder milk, B starch powder milk or wheat mixed powder milk), when the wheat starch milk contacts the lower gear Turn on the stirring blade when stirring, close the feed valve after feeding, take a sample to measure the concentration, calculate the amount of dry starch and the amount of enzyme added, and then add water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com