Molten tin protective agent

A technology of protective agent and molten liquid, applied in coating, metal material coating process, hot dip plating process, etc., can solve the problems of increasing labor cost and power consumption, poor electrical insulation performance, burning machines, etc., and achieve excellent The effect of electrical insulation performance and reliability of use, reduction of electricity consumption, and reduction of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A tin melt protective agent, based on the total weight of the protective agent, it consists of the following components: tripalmitolein 10%, arachidonic acid 75%, liquid polybutene 5% and high viscosity Dimethicone oil (viscosity 5000cps at 20°C) 10%. Stir the above components in proportion at a temperature of 140-160°C to form a homogeneous liquid, filter and fill for use.

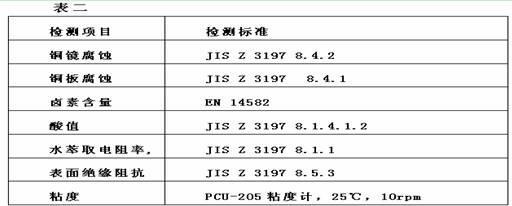

[0029] The physical and chemical performance indicators of the protective agent in this embodiment are shown in Table 1, and the standards on which the performance testing is based are shown in Table 2.

Embodiment 2

[0031] A tin melt protective agent, based on the total weight of the protective agent, it consists of the following components: 10% pentaerythritol tetrapalmitoleate, 65% arachidonic acid, 15% liquid polybutene and high viscosity Simethicone oil (viscosity 20000cps at 20°C) 10%. The preparation method is the same as in Example 1, and will not be repeated here.

[0032] The physical and chemical performance indicators of the protective agent in this embodiment are shown in Table 1, and the standards on which the performance testing is based are shown in Table 2.

Embodiment 3

[0034] A tin melt protective agent, based on the total weight of the protective agent, it consists of the following components: 10% pentaerythritol tetralinoleate, 80% docos-6-enoic acid, 5% liquid polyisobutylene % and high viscosity simethicone oil (20000cps viscosity at 20°C) 5%. The preparation method is the same as in Example 1, and will not be repeated here.

[0035] The physical and chemical performance indicators of the protective agent in this embodiment are shown in Table 1, and the standards on which the performance testing is based are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com