High-power simplified electrolytic and electroplating high-frequency switch power supply and control method thereof

A high-frequency switching power supply, electrolytic plating technology, applied in control/regulation system, output power conversion device, DC power input conversion to DC power output, etc., can solve the problem of increased capacity of power transformer switches, large diode rectifier circuits, Problems such as large harmonic content in the power grid, to achieve the effects of suppressing current disturbances, realizing high-efficiency utilization, and good output waveforms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

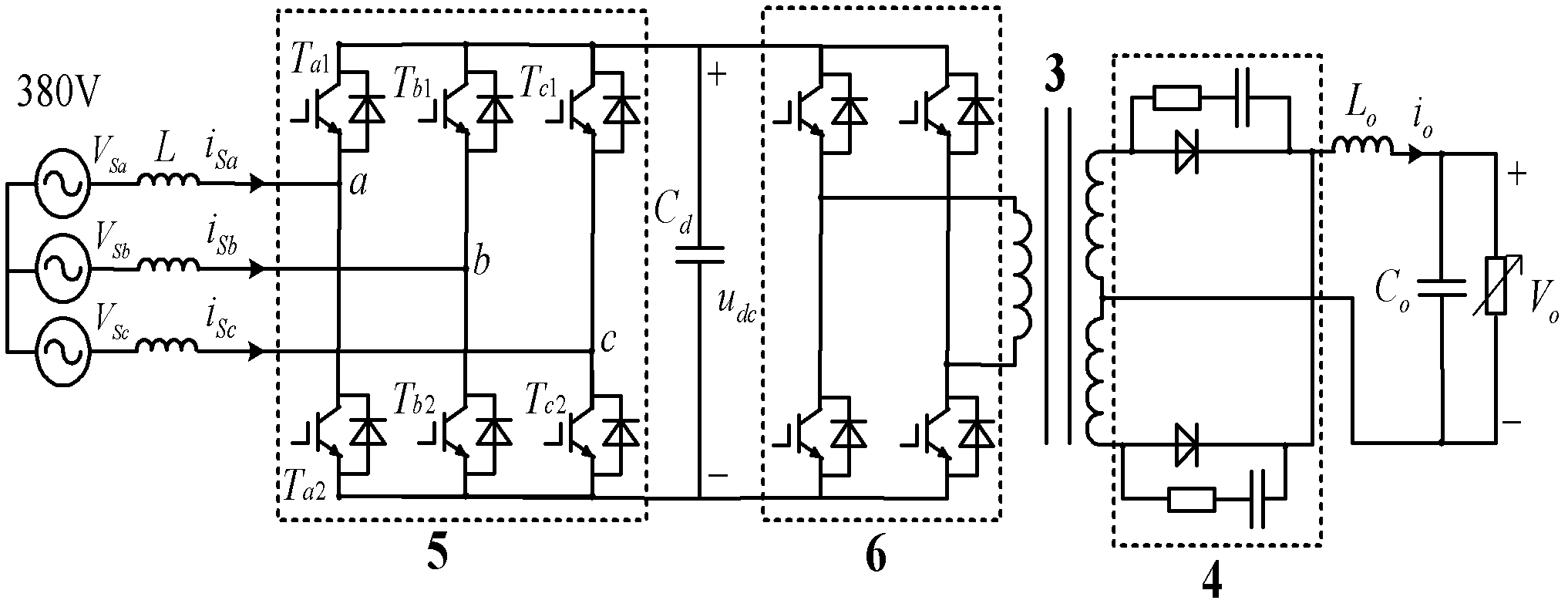

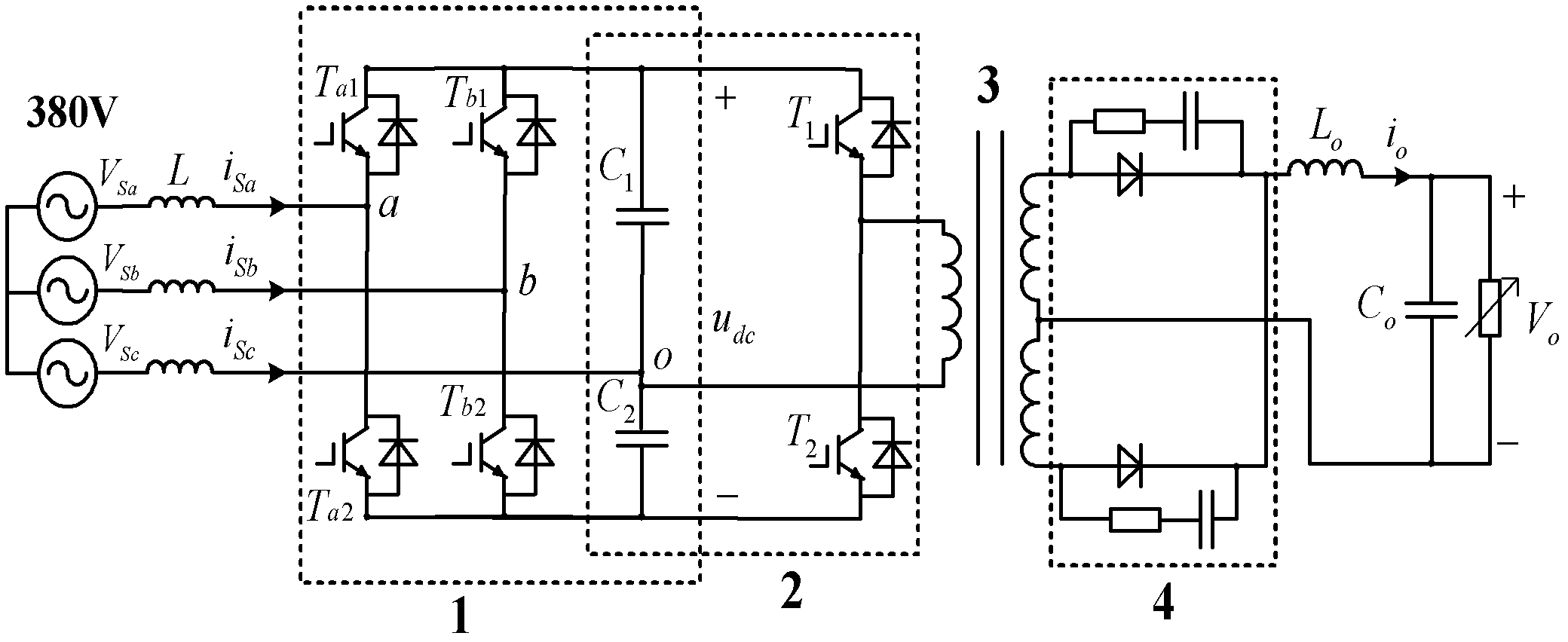

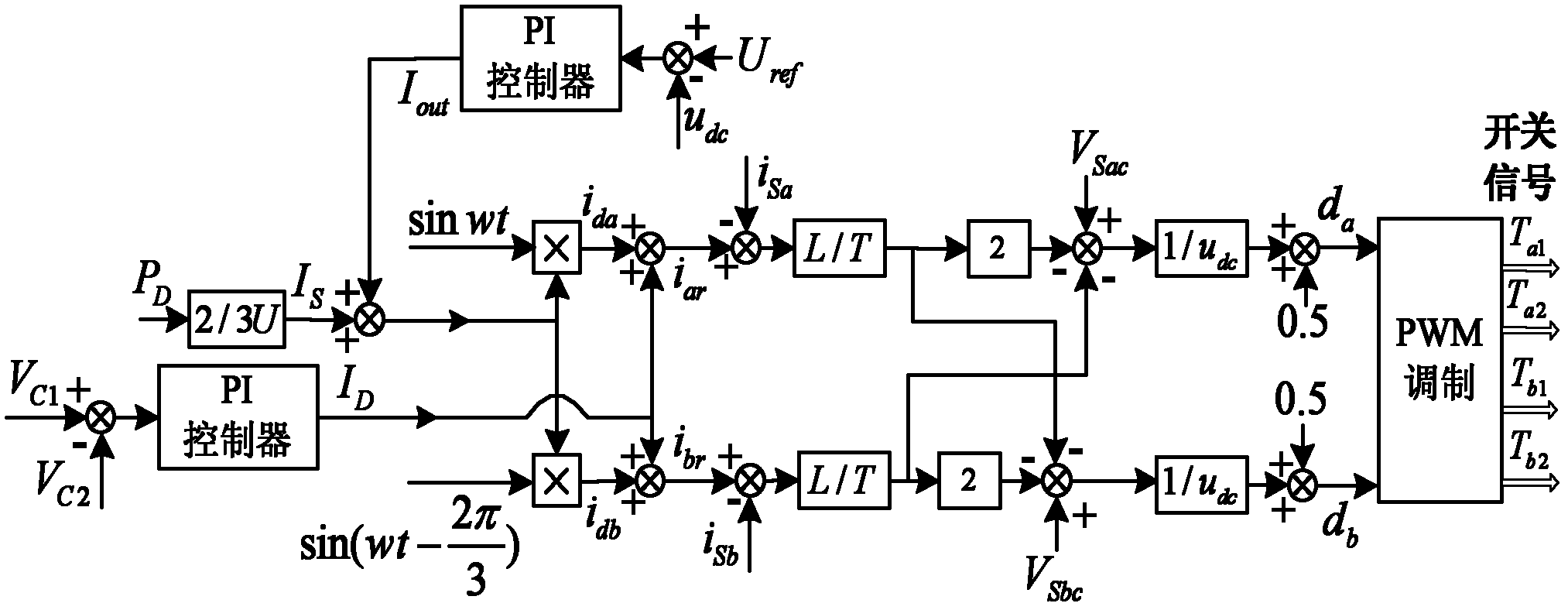

[0035] See figure 1 , Is the structure diagram of general high-power electrolytic plating high-frequency switching power supply. It includes a three-phase inverter 5, a single-phase full-bridge inverter 6, a high-frequency coupling transformer 3 and a low-voltage full-wave rectifier 4. The three-phase inverter 5 is a general voltage type inverter, which is composed of 3 switch arms, namely 6 power switches. Its AC input side is connected to the grid through a three-phase inductor L, and its DC side is connected to the grid through a capacitor C d Connect the next level circuit. In the figure, a single-phase full-bridge inverter 5, a high-frequency coupling transformer 3 and a low-voltage full-wave rectifier 4 constitute a high-frequency DC / DC converter. Among them, the single-phase full-bridge inverter 6 is a general voltage type inverter, which is composed of two switch arms, that is, four power switches.

[0036] After the three-phase alternating current is rectified by the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com