Heat pump regeneration process for desulphurization solvent used in flue gas desulphurization by solvent cyclic absorption method

A solvent circulation and absorption technology, applied in separation methods, heat recovery systems, climate sustainability, etc., can solve the problems of high energy consumption, hinder the popularization and application of solvent circulation absorption flue gas desulfurization process, and achieve low energy consumption and low energy consumption. Operating costs and the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

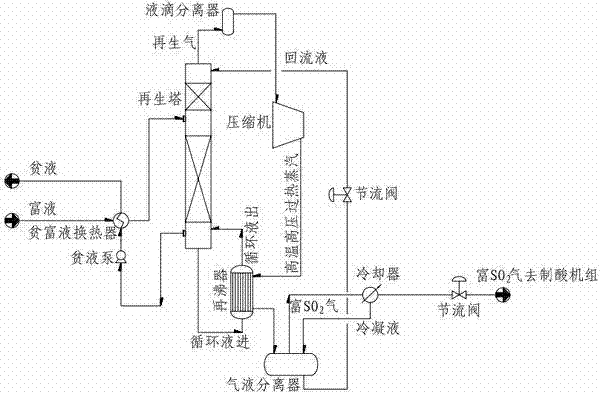

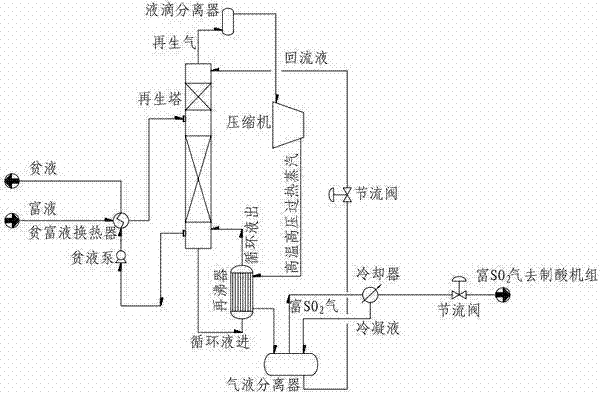

[0025] Taking the heat pump regeneration of the desulfurization solvent in the flue gas desulfurization of the sintering flue gas of the iron and steel plant as an example, combined with figure 1 The present invention will be described.

[0026] The desulfurization solvent-rich liquid from the desulfurization section is heated to 90°C through the lean-rich liquid heat exchanger and the desulfurization solvent lean liquid from the bottom of the regeneration tower, and then sent to the regeneration tower. The steam rising from the kettle is used for countercurrent contact, and the SO contained in it is desorbed by heating and stripping. 2 and make it regenerate. The desulfurized solvent lean liquid obtained after desorption is discharged from the tower kettle, and after heat exchange with the rich liquid by the lean liquid heat exchanger, it enters the lean liquid cooler, and is cooled to 31°C by water cooling before being sent to the desulfurization section for use.

[0027]T...

Embodiment 2

[0030] Taking the heat pump regeneration of the desulfurization solvent in the flue gas desulfurization of the sintering flue gas of the iron and steel plant as an example, combined with figure 1 The present invention will be described.

[0031] The desulfurization solvent-rich liquid from the desulfurization section is heated to 100°C through the lean-rich liquid heat exchanger and the desulfurization solvent lean liquid from the bottom of the regeneration tower, and then sent to the regeneration tower. The steam rising from the kettle is used for countercurrent contact, and the SO contained in it is desorbed by heating and stripping. 2 and make it regenerate. The desulfurized solvent lean liquid obtained after desorption is discharged from the tower kettle, and after heat exchange with the rich liquid through the lean liquid heat exchanger, it enters the lean liquid cooler, and is cooled to 38°C by water cooling before being sent to the desulfurization section for use.

[...

Embodiment 3

[0035] Taking the heat pump regeneration of the desulfurization solvent in the flue gas desulfurization of the sintering flue gas of the iron and steel plant as an example, combined with figure 1 The present invention will be described.

[0036] The desulfurization solvent-rich liquid from the desulfurization section is heated to 96°C through the lean-rich liquid heat exchanger and the desulfurization solvent lean liquid from the bottom of the regeneration tower, and then sent to the regeneration tower. The steam rising from the kettle is used for countercurrent contact, and the SO contained in it is desorbed by heating and stripping. 2 and make it regenerate. The desulfurized solvent lean liquid obtained after desorption is discharged from the tower kettle, and after heat exchange with the rich liquid through the lean liquid heat exchanger, it enters the lean liquid cooler, and is cooled to 34°C by water cooling before being sent to the desulfurization section for use.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com