Method for preparing hierarchical structure bismuth oxybromide hollow microsphere photocatalysis material

A photocatalytic material, bismuth oxybromide technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low photocatalytic efficiency and low cost, and achieve high photocatalytic performance and cost. Low, improved separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Dissolve 0.97 g of bismuth nitrate and 1.17 g of 1-hexadecyl-3-methylimidazole bromide in 40 mL of ethylene glycol methyl ether, and magnetically stir for 30 minutes to dissolve completely. The two solutions were then mixed and stirring was continued for 10 minutes;

[0018] (2) Transfer the above-mentioned mixed solution to a closed autoclave, and place it at 160° C. for 0.5 hours to react;

[0019] (3) After cooling to room temperature, the product was collected, washed, and vacuum-dried.

Embodiment 2

[0021] (1) Dissolve 0.97g of bismuth nitrate and 1.17g of 1-hexadecyl-3-methylimidazole bromide in 40mL of ethylene glycol methyl ether, and magnetically stir for 30 minutes to dissolve them completely, and then mix the two solutions Mix and continue stirring for 10 minutes;

[0022] (2) Transfer the above mixed solution to a closed autoclave, and place it at 160° C. for 2 hours;

[0023] (3) After cooling to room temperature, the product was collected, washed, and vacuum-dried.

Embodiment 3

[0025] (1) Dissolve 0.97g of bismuth nitrate and 1.17g of 1-hexadecyl-3-methylimidazole bromide in 40mL of ethylene glycol methyl ether, and magnetically stir for 30 minutes to dissolve them completely, and then mix the two solutions Mix and continue stirring for 10 minutes.

[0026] (2) Transfer the above mixed solution to a closed autoclave, and place it at 160° C. for 12 hours;

[0027] (3) After cooling to room temperature, the product was collected, washed, and vacuum-dried.

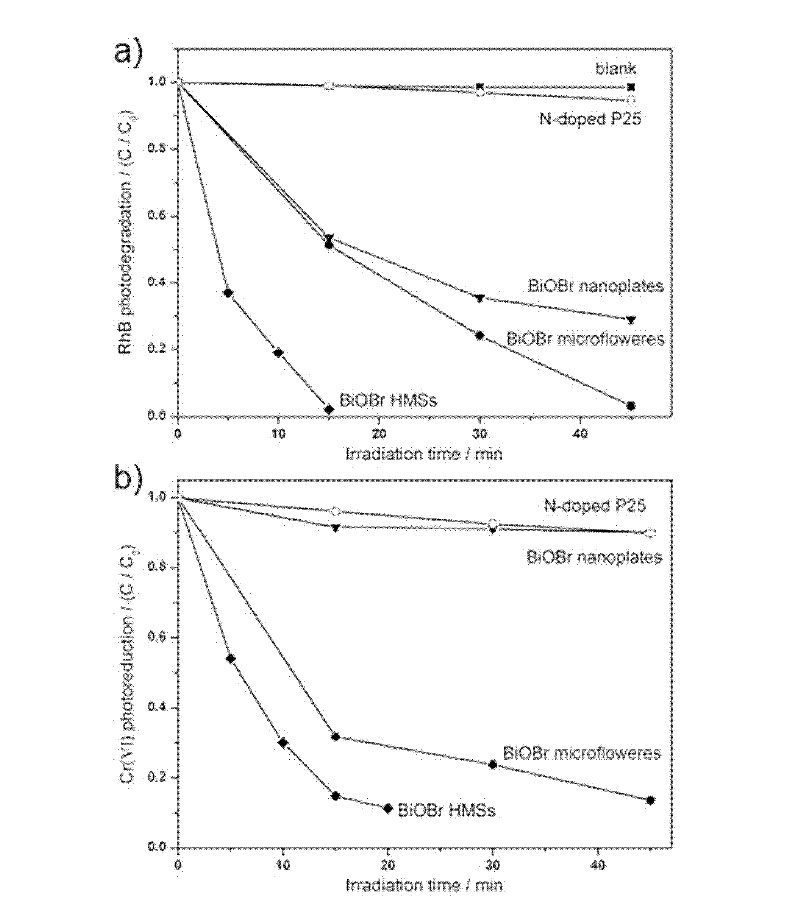

[0028] Photocatalytic performance test

[0029] The photocatalytic performance of the material was characterized by degradation of rhodamine B dye and reduction of hexavalent metal chromium ions under visible light. A xenon lamp (300 watts) with a UV filter was used as the light source. The photocatalytic material powder is dispersed in a certain concentration of rhodamine B dye or hexavalent chromium ion solution, placed in a dark place and continuously magnetically stirred for a period of time,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com