Cloud paraffin

A technology of paraffin and sorbitan, applied in polishing compositions, chemical instruments and methods, etc., can solve the problems of limited use range, inability to use stone surface polishing, etc., achieves economical efficiency, environmental friendliness, and improves smoothness and smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weighing by weight: 5 parts of paraffin wax, 3 parts of microcrystalline wax and 2 parts of beeswax, 6 parts of sorbitan monostearate and 9 parts of polyoxyethylene (20EO) sorbitan monostearate 5 parts of diethylene glycol, 1.6 parts of simethicone, 1 part of sulfonated fatty acid alkyl ester, and 80 parts of water.

preparation example

[0019] A) Melting the mixed paraffin wax, adding 5 parts of paraffin wax, 3 parts of microcrystalline wax and 2 parts of beeswax to a reaction vessel equipped with a heating and stirring device such as a reactor to melt, and controlling the melting temperature to 90°C to obtain Mixed paraffin melt;

[0020] B) Emulsification, turn on the stirring device of the reaction vessel described in step A), and add 6 parts of compound emulsifier sorbitan monostearate to the mixed paraffin wax melt at 500 rpm , 9 parts of polyoxyethylene (20EO) sorbitan monostearate, 5 parts of co-emulsifier diethylene glycol and 20 parts of water, after the addition is completed, the stirring speed is 1000 rpm under the state of rapid stirring for emulsification After 25 minutes, a water-in-oil emulsion (called O / W emulsion in the industry customarily) is obtained;

[0021] C) To prepare the finished emulsion, add 60 parts of water, 1.6 parts of simethicone oil as a brightening agent and 1 part of sulf...

Embodiment 2

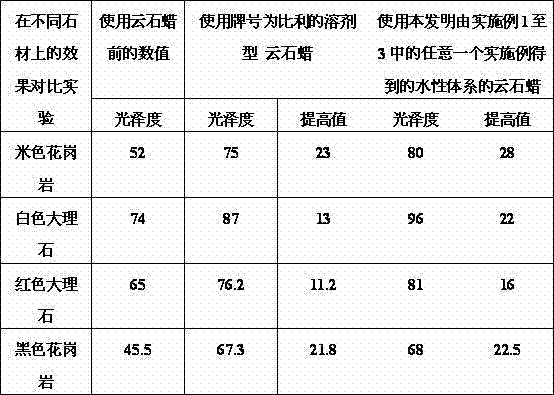

[0023] A kind of cloud paraffin wax, it is made of the raw material of following proportioning by weight: 10 parts of paraffin wax, 6 parts of ozokerite and 2 parts of beeswax, 4 parts of sorbitan monooleate, polyoxyethylene (20EO) sorbitan 6 parts of alcohol monooleate and 2 parts of triethanolamine, 8 parts of ethylene glycol, 65 parts of water, 1.6 parts of simethicone, 1 part of sulfonated fatty acid alkyl ester, and 0.6 part of dioctyl sodium sulfosuccinate. Obtain the semi-paste finished cloud paraffin wax of technical effect shown in Table 1 and Table 2 by above-mentioned preparation example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com