Method of treating oil sludge with surfactant

A surfactant and oil sludge technology, which is applied in the field of treating oil sludge with surfactants, can solve the problems of biosurfactant production costs limiting commercial applications, and achieve the effects of less secondary pollution, low temperature, and high emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

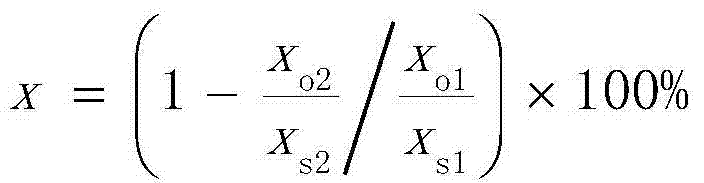

Method used

Image

Examples

Embodiment 1

[0021] The aqueous solution of sodium cholate with a concentration of 0.1g / L (the price of feed-grade sodium cholate used in this example is between 8,000 and 10,000 yuan / ton) was used to sprinkle crude oil on the farmland soil in Ma'an Village, Changzhi Island. The ground oil sludge formed within 3 days is subjected to thermochemical washing treatment, the stirring speed is 200r / min, the mass ratio of the aqueous solution of sodium cholate to the ground oil sludge is 2:1, the washing temperature is 50°C, and the washing time is 30min. The pH value of the aqueous solution was adjusted to 9 with 0.1 mol / L NaOH aqueous solution. The resulting treated oily sludge is designated as sample 1.

[0022] The washing efficiency of the sample 1 was measured, and the washing efficiency of the sample 1 was 87.5%.

[0023] Follow the same procedure as above, only replacing the aqueous solution of sodium cholate at a concentration of 0.1 g / L with Na at a concentration of 5 g / L 2 CO 3 Aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com