Chromium-contaminated soil repair agent and preparation method thereof

A technology of chromium-contaminated soil and repair agent, which is applied in the field of soil restoration, and achieves the effect of broad market prospect, low production cost and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

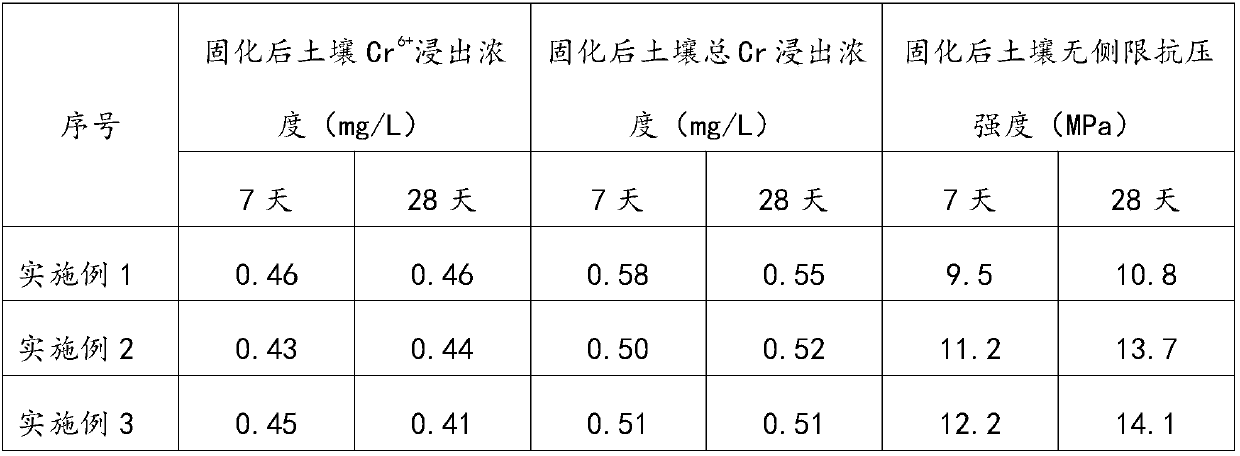

Examples

Embodiment 1

[0021] The chromium-contaminated soil remediation agent of the present embodiment is made of the following raw materials: 10 kg of calcium hydroxyphosphate with 400 meshes, 15 kg of sodium carbonate, 6 kg of palmitic acid, 15 kg of zeolite, 10 kg of calcium chloride, 15 kg of ground steel slag, 6kg of fine slag, 16kg of ferrous sulfate, 10kg of epoxy resin and 16kg of calcium lignosulfonate.

[0022] The preparation method of the above-mentioned chromium-contaminated soil remediation agent comprises the steps of: getting raw materials of the following weight: 400 mesh calcium hydroxyphosphate 10kg, sodium carbonate 15kg, palmitic acid 6kg, zeolite 15kg, calcium chloride 10kg, ground steel slag 15kg , 6kg of finely ground slag, 16kg of ferrous sulfate, 10kg of epoxy resin and 16kg of calcium lignosulfonate, after mixing evenly, grind until the Blaine specific surface area is 360m 2 / Kg to obtain the chromium-contaminated soil remediation agent.

Embodiment 2

[0024] The chromium-contaminated soil remediation agent of the present embodiment is made of the following raw materials: 20 kg of calcium hydroxyphosphate, 10 kg of sodium carbonate, 10 kg of palmitic acid, 10 kg of zeolite, 15 kg of calcium chloride, 10 kg of ground steel slag, 10 kg of milled steel slag, Fine slag 11kg, ferrous sulfate 10kg, epoxy resin 15kg and calcium lignosulfonate 11kg.

[0025] The preparation method of the above-mentioned chromium-contaminated soil remediation agent comprises the steps of: taking raw materials of the following weight: calcium hydroxyphosphate 20kg, sodium carbonate 10kg, palmitic acid 10kg, zeolite 10kg, calcium chloride 15kg, ground steel slag 10kg, ground slag 11kg , 10kg of ferrous sulfate, 15kg of epoxy resin and 11kg of calcium lignosulfonate, after mixing evenly, grind until Blaine's specific surface area is 380m 2 / Kg to obtain the chromium-contaminated soil remediation agent.

Embodiment 3

[0027] The chromium-contaminated soil remediation agent of the present embodiment is made of the following raw materials: 30 kg of 400 mesh calcium hydroxyphosphate, 5 kg of sodium carbonate, 15 kg of palmitic acid, 5 kg of zeolite, 20 kg of calcium chloride, 5 kg of finely ground steel slag, 16kg of fine slag, 4kg of ferrous sulfate, 20kg of epoxy resin and 6kg of calcium lignosulfonate.

[0028] The preparation method of the above-mentioned chromium-contaminated soil remediation agent comprises the steps of: taking raw materials of the following weight: calcium hydroxyphosphate 30kg, sodium carbonate 5kg, palmitic acid 15kg, zeolite 5kg, calcium chloride 20kg, ground steel slag 5kg, ground slag 16kg , 4kg of ferrous sulfate, 20kg of epoxy resin and 6kg of calcium lignosulfonate, after mixing evenly, grind until Blaine specific surface area is 400m 2 / Kg to obtain the chromium-contaminated soil remediation agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com