High-speed burner impulse tunnel furnace

A high-speed burner and tunnel furnace technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems of outdated control means, small range of fuel adaptation, and reduce the temperature difference of the atmosphere, so as to enhance the convection heat transfer in the furnace, The fuel is suitable for a wide range and improves the effect of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

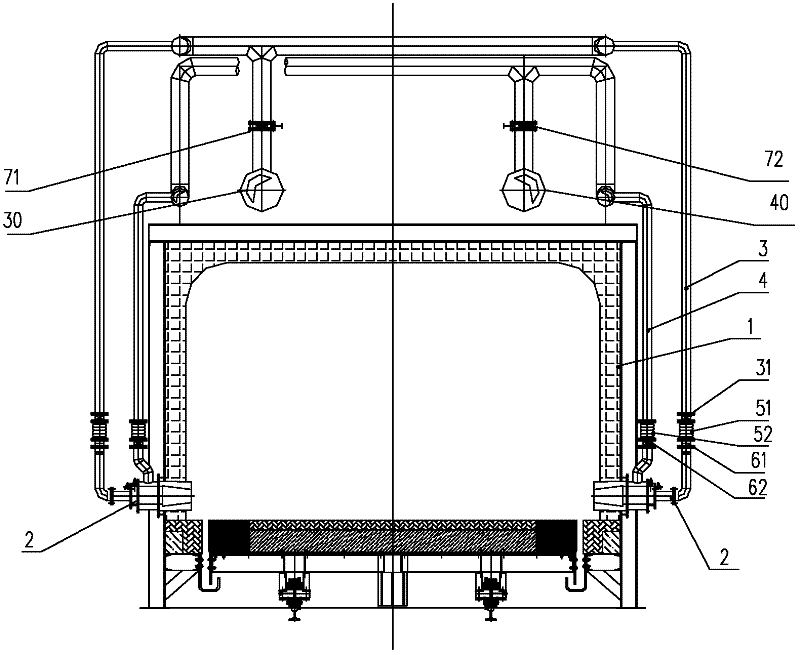

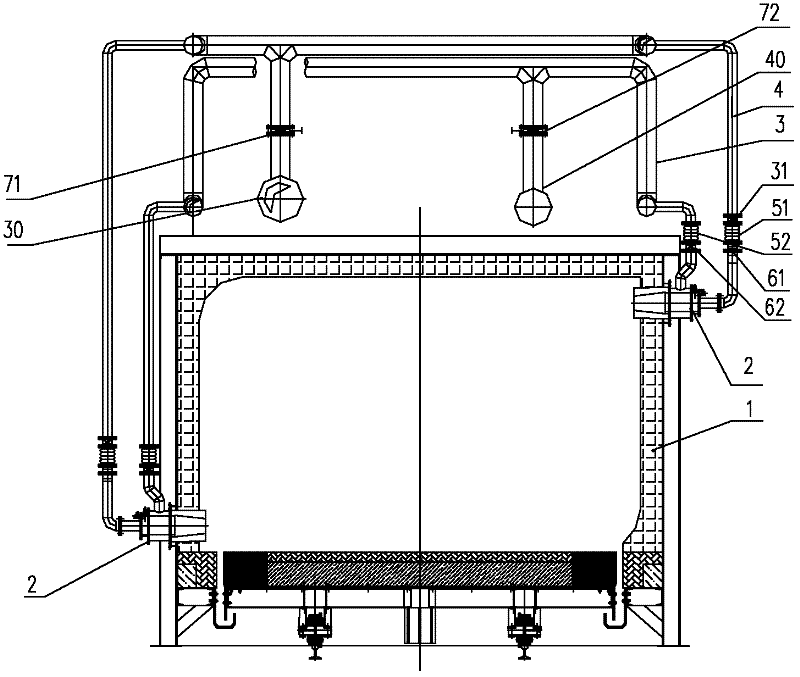

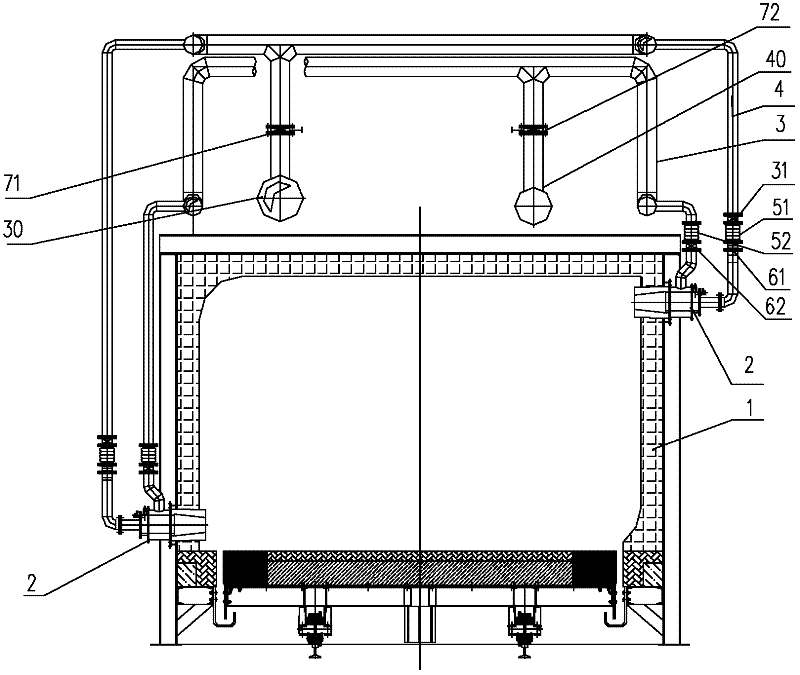

[0017] refer to figure 1 , the high-speed burner pulse tunnel furnace of the present invention comprises a furnace body 1, 2 high-speed burners 2, a gas pipeline 3, an air pipeline 4, a gas shut-off valve 31 and 2 manual regulating valves, 2 pulse control valves and a combustion control device .

[0018] Two high-speed burners 2 are installed on the lower ends of the two side walls of the furnace body 1 respectively. One end of the gas pipeline 3 is a gas inlet 30, the other end of the gas pipeline 3 communicates with the gas inlet of the high-speed burner 2, one end of the air pipeline 4 is an air inlet 40, and the other end of the air pipeline 4 communicates with the air inlet of the high-speed burner 2.

[0019] The first manual regulating valve 61 is installed on the gas pipeline 3 before the high-speed burner 2 , and the second manual regulating valve 62 is installed on the air pipeline 4 before the high-speed burner 2 . The gas shut-off valve 31 is installed on the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com