Dexibuprofen sustained-release pellet and preparation method thereof

A technology for sustained-release pellets and pellets, which is applied in the directions of pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc. It can improve the bioavailability, reduce the interaction, and have good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

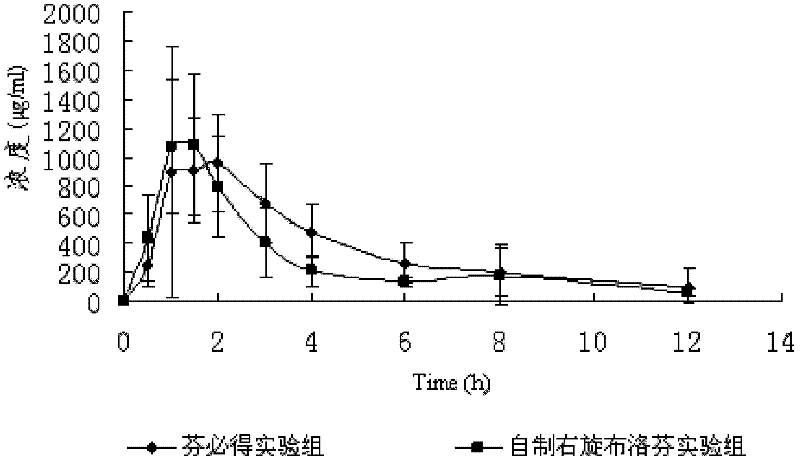

Image

Examples

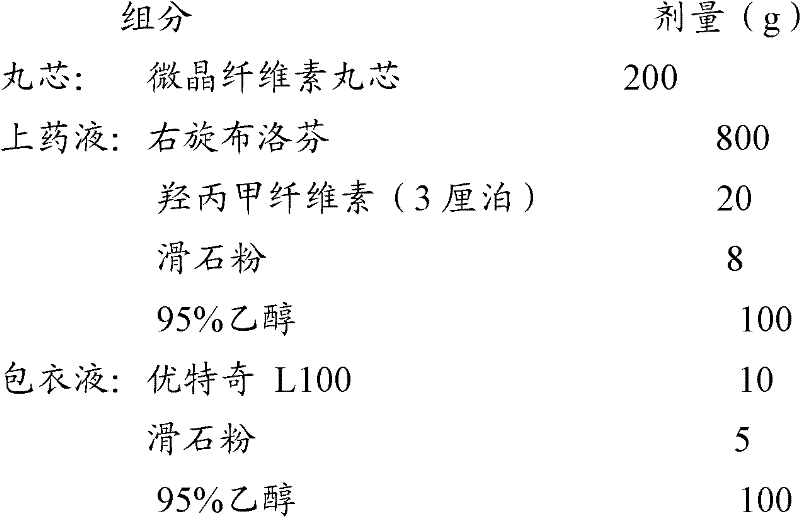

Embodiment 1

[0042] formula:

[0043]

[0044] First prepare the drug solution and coating solution, in the fluidized bed, control the temperature of the material at 30°C, spray the drug at the bottom, and obtain 18-20 mesh uncoated pellets, take 18-20 mesh uncoated pellets For coating, stir while adding the solution to avoid sedimentation of the talcum powder. Capsules are filled according to the content to obtain 200mg specification Dexibuprofen sustained-release capsules. The preparation process of the micropills was smooth, the appearance was round and beautiful, and the micropills were stored without adhesion. The uncoated micropills released relatively fast in the in vitro release test, and passed the coating after coating.

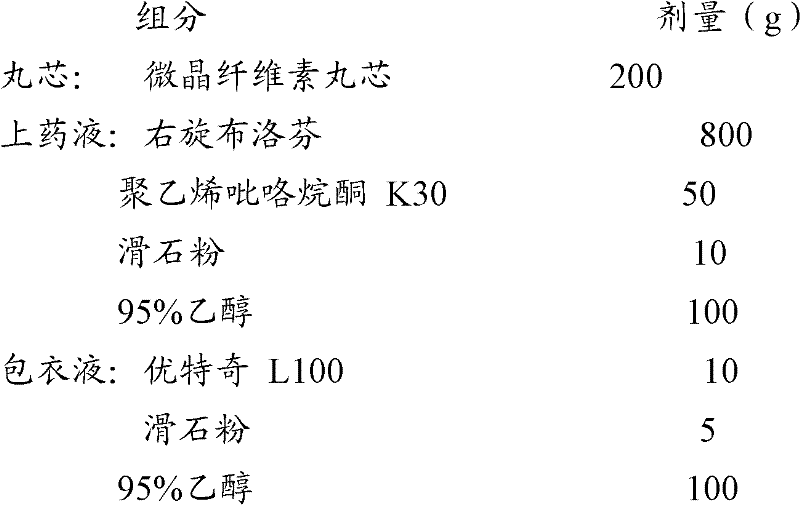

Embodiment 2

[0046] formula:

[0047]

[0048] First prepare the drug solution and coating solution, in the fluidized bed, control the temperature of the material at 30°C, spray the drug at the bottom, and obtain 18-20 mesh uncoated pellets, take 18-20 mesh uncoated pellets For coating, stir while adding the solution to avoid talcum powder settling. During the preparation and storage of pellets, pellet adhesion may occur. Add appropriate amount of talc powder to prevent adhesion. The adhesion of pellets after coating is good. Fill the capsules according to the content to obtain 200mg Dexibuprofen sustained-release capsules. In vitro release test The uncoated pellets were synthesized, and the release of coated pellets was slow.

Embodiment 3

[0050] formula:

[0051]

[0052] First prepare the drug solution and coating solution, in the fluidized bed, control the temperature of the material at 30°C, spray the drug at the bottom, and obtain 18-20 mesh uncoated pellets, take 18-20 mesh uncoated pellets For coating, stir while adding the solution to avoid talcum powder settling. During the preparation and storage of pellets, pellet adhesion may occur. Add appropriate amount of talc powder to prevent adhesion. The adhesion of pellets after coating is good. Fill the capsules according to the content to obtain 200mg Dexibuprofen sustained-release capsules. In vitro release test The uncoated pellets were synthesized, and the release of coated pellets was slow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com