Micropore filter material sintered plate for dust separator

A technology of plastic sintering plate and dust collector, which is applied in the fields of filtration of dispersed particles, chemical instruments and methods, separation of dispersed particles, etc., can solve the problems of intractable dust, and achieve the effect of avoiding filtration pressure loss, saving occupied space and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

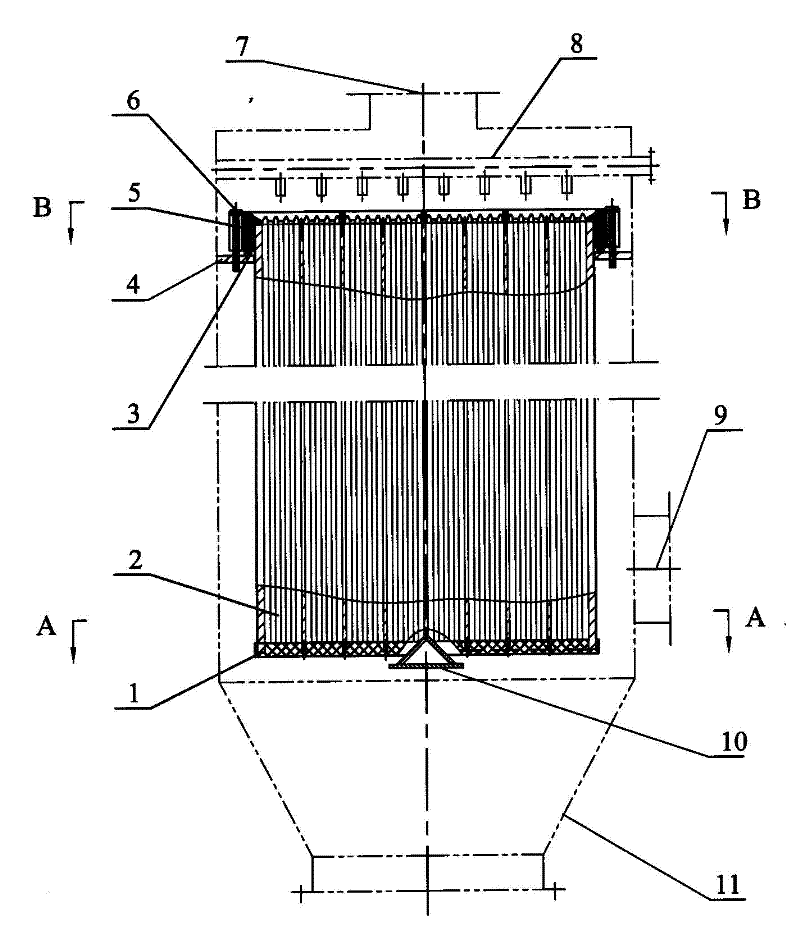

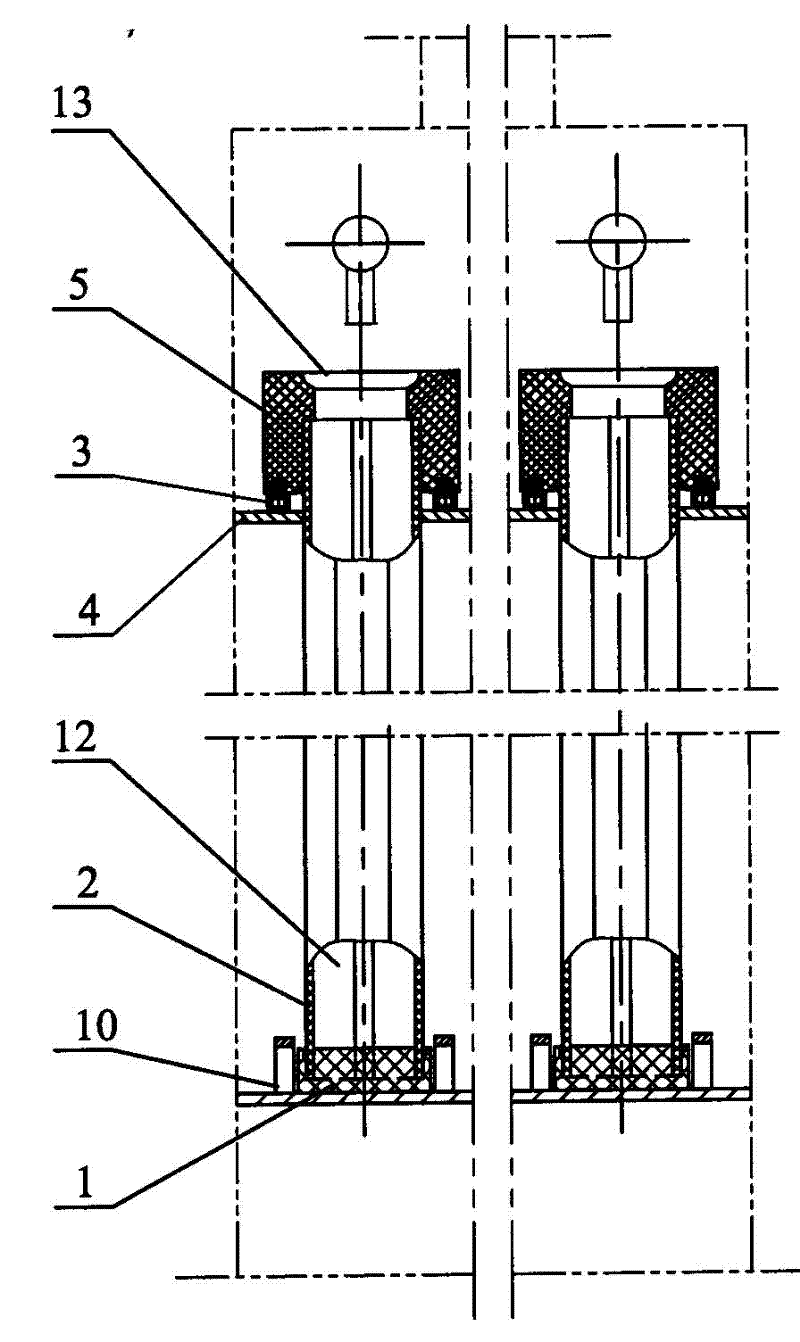

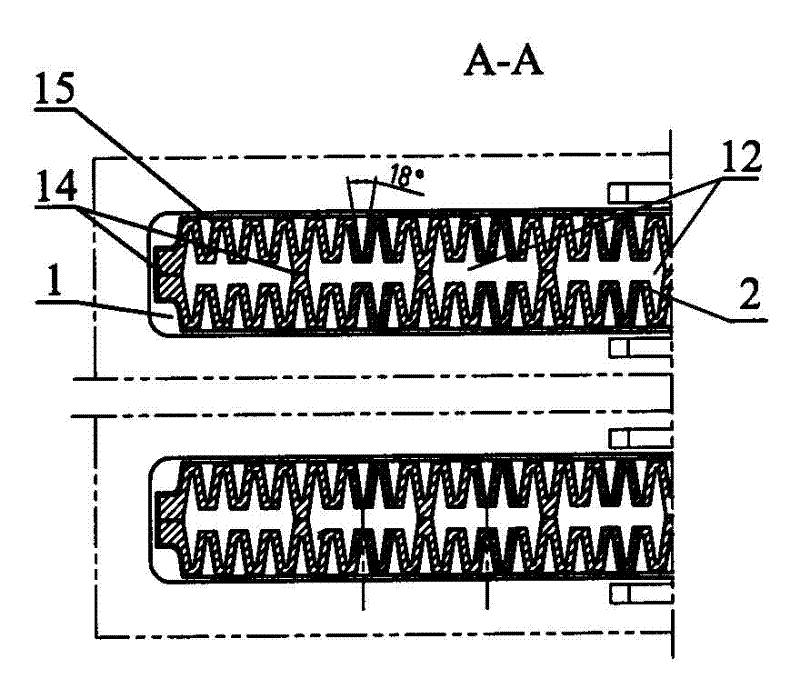

[0015] according to Figure 1~4 The specific structure of the present invention will be described in detail. The microporous filter plastic sintered plate for the dust collector mainly includes the microporous plastic sintered plate body 2 formed by sintering the polymer compound, the partition plate 4 and the bottom frame for fixing the plastic sintered plate body 2 and the dust collector housing 11 10 and other components. The housing 11 of the dust collector, the clean gas outlet 7, the dusty gas inlet 9, the blowing pipe 8 with nozzles connected to the compressed air and the bottom dust discharge device, etc., all adopt the same kind of products in the prior art. Generic structure. The microporous plastic-sintered plate body 2, which allows airflow to pass through but not dust to pass through, is composed of two V-shaped corrugated plates with a symmetrical structure and an included angle of 18 degrees in cross section. In this embodiment, the polymer compound (mainly m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com