Multi-functional simulation experiment system for mining elevator

It is a simulation experiment and multi-functional technology, which is applied in the lifting equipment, elevators, transportation and packaging in the mine, and can solve the problems of unbalanced tension force of the traction rope, fast running speed, lack of water-drenching environment for the car, etc. To achieve the effect of compact structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

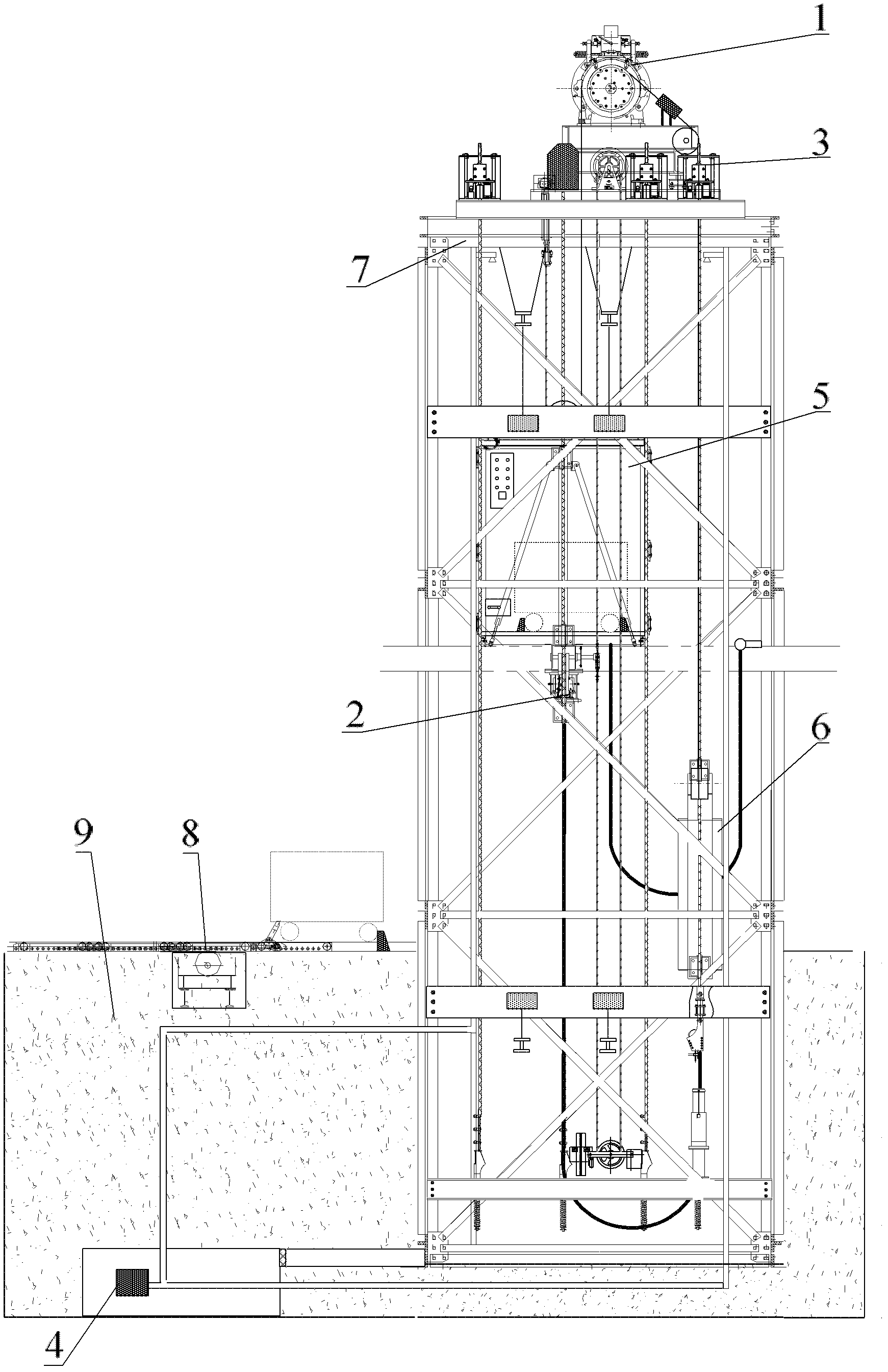

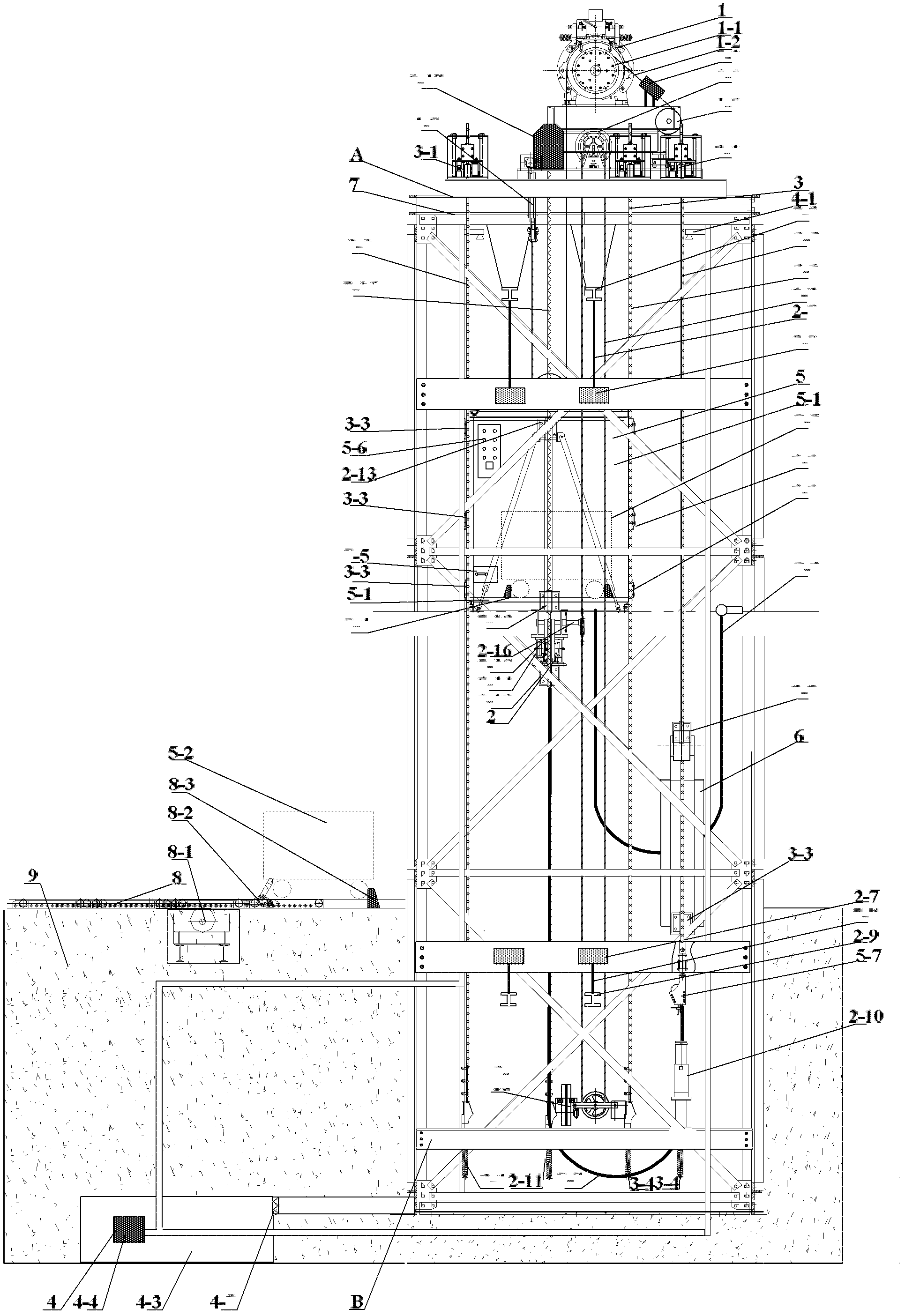

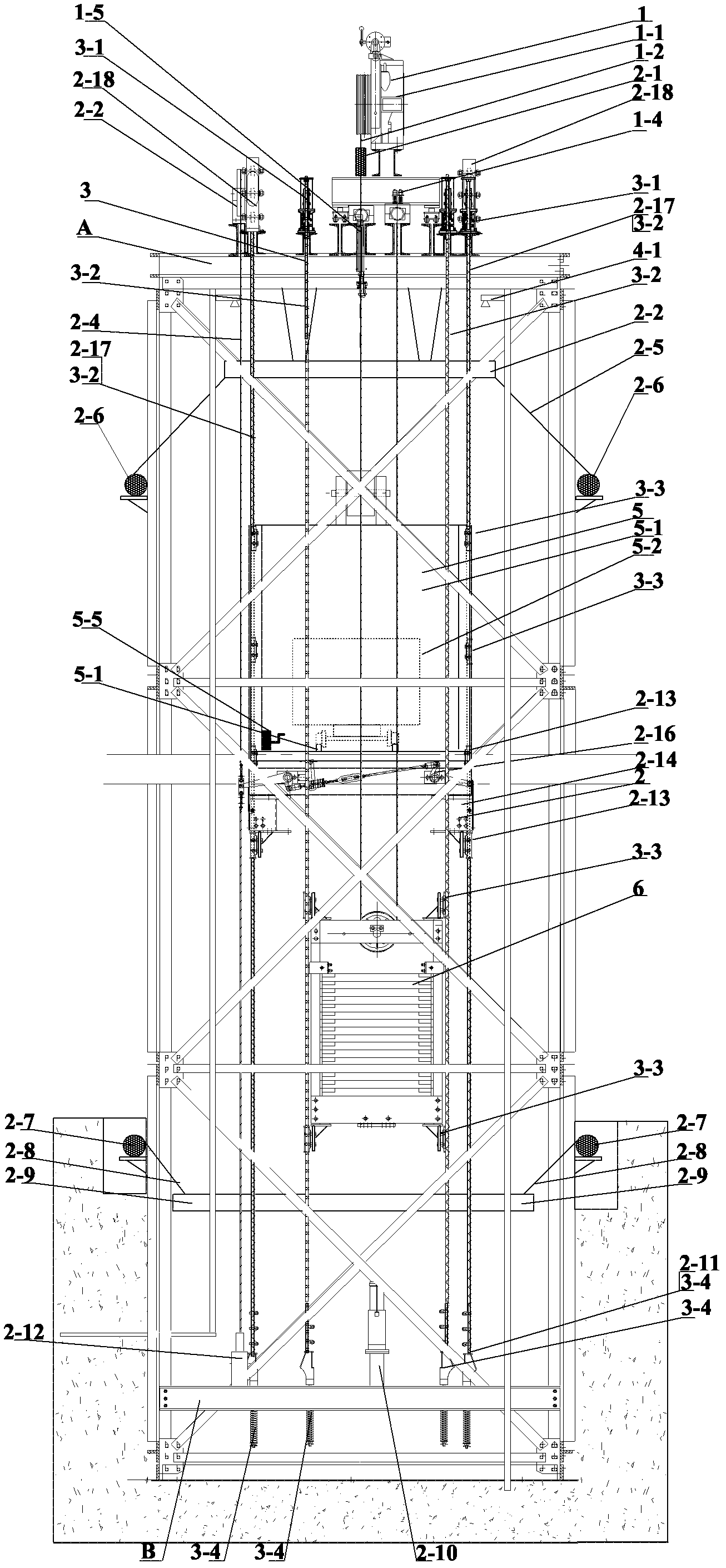

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] The mine elevator multifunctional simulation experiment system of the present invention mainly consists of a derrick 7 fixed on the concrete base 9, an explosion-proof traction test system 1 which is arranged on the top of the derrick 7 for pulling the car 5 to run up and down, and a car protection test. System 2, flexible guide rail guiding test system 3, water spraying simulation test system 4, car 5 and counterweight 6 are composed of a mine car moving device 8 on the concrete base 9; the mine car moving device 8 includes The track on the 9, the cart machine 8-1 that is located under the track, the cart machine 8-1 is provided with the push claw 8-2 that pushes the mine car, and the track both sides of the mine car 5-2 entrance is provided with a stopper. Car device 8-3; car 5 inner bottom is provided with track 5-1, and track 5-1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com