High-performance elastic alloy material for aerial hyperbaric cabin and production method thereof

An elastic alloy and production method technology, applied in the field of new high-performance elastic materials, can solve problems such as restricting the development and application of alloys, and achieve the effects of narrowing the tolerance range, ensuring resistance uniformity, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

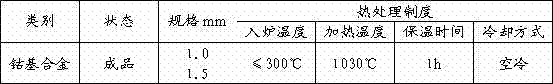

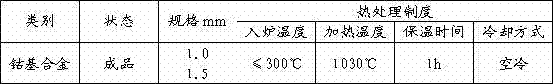

Image

Examples

Embodiment 1

[0031] High-performance elastic alloy material for aviation hyperbaric cabin, its chemical composition is (wt.%): Ni 15%, Cr 19%, Co 40%, Si 0.6%, Mn 2%, C 0.08%, P 0.01%, S 0.01%, Mo 7%, Ti 0.5%, Al 0.3%, lanthanum-cerium alloy 0.5%, Fe 15%.

Embodiment 2

[0033] High-performance elastic alloy material for aviation hyperbaric cabin, its chemical composition is (wt.%): Ni 14%, Cr 20%, Co 39%, Si 0.3%, Mn 2.2%, C 0.1%, P 0.01%, S 0.01%, Mo 6.5%, Ti 1%, Al 0.2%, Lanthanum-cerium alloy 0.5%, Fe 16.18%.

Embodiment 3

[0035] High-performance elastic alloy material for aviation hyperbaric cabin, its chemical composition is (wt.%): Ni 17%, Cr 21%, Co 40%, Si 0.3%, Mn 1.7%, C 0.07%, P 0.01%, S 0.01%, Mo 6.5%, Ti 0.35%, Al 0.4%, lanthanum-cerium alloy 0.5%, Fe 12.16%.

[0036] The production method of above embodiment 1-3 comprises the following steps:

[0037] 1. Vacuum melting:

[0038] (1) Raw material preparation: the charge is Ni plate, metal Cr, industrial pure Fe and metal Mn, Co and other materials, which are baked and used for later use;

[0039] (2) Charging: Load Ni, Cr, Fe, Co furnace materials that have been baked into the intermediate frequency smelting furnace, and put C, Mn, Si, and lanthanum-cerium alloys into the material cup.

[0040] (3), refining:

[0041] For low-power chemical materials, after the material is 70% melted, increase the power to melt at a high speed. When it is fully melted, it will enter the refining period after reaching the refining temperature. Refin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com