Coded lock permanent magnet assembly locking device

A technology of permanent magnets and lockers, which is applied in the application of electromagnets, building locks, locks, etc., can solve the problems of high power consumption of electromagnetic coils, easy jamming of iron rod support spring 5, and impact on safety, etc., to achieve Improve the safety and reliability level, eliminate the hidden danger of illegal unlocking, and prolong the effect of battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

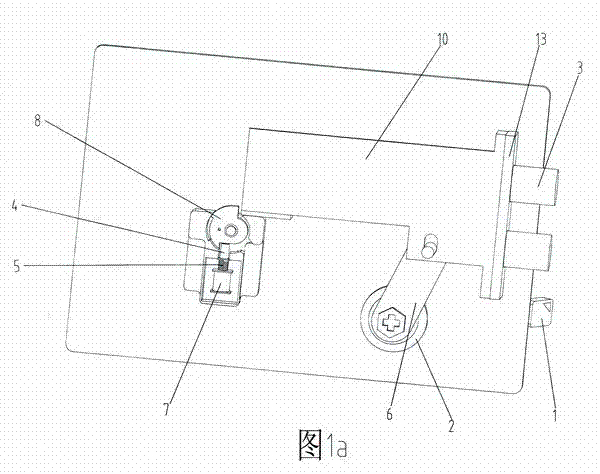

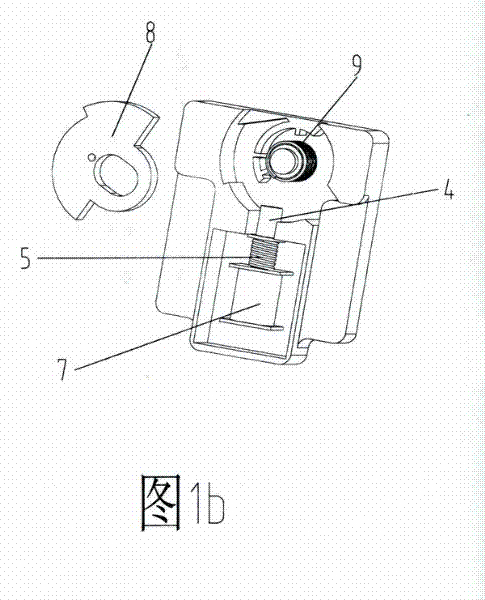

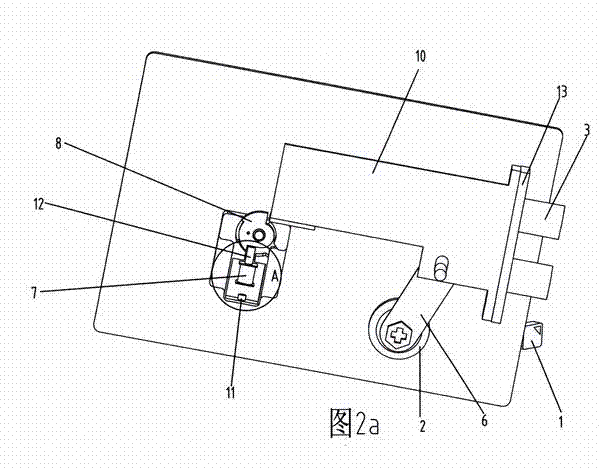

[0015] see Figure 2a , Figure 2b with Figure 2c As shown, the mechanical parts of the electronic combination lock include a key 1 , a lock cylinder 2 , a lock cylinder bolt connecting rod 6 , a cam block 8 , a deadbolt linkage 10 , and a deadbolt 3 . Figure 2a Indicates the back of the lockset, the lower end of the lock cylinder and bolt connecting rod 6 is connected to the lock cylinder 2, and the upper end is connected to the bolt linkage 10, the bolt 3 at the front end of the bolt linkage 10 passes through the locking frame 13, and the bolt linkage The lower part of the rear end of 10 is arranged to be in contact with the vertical plane of the upper end of the cam block 8. The permanent magnet assembly is arranged under the cam block 8, including the electromagnetic coil 7, and the permanent magnet rod 12 arranged in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com