Hollow needle beam lining trolley

A technology of lining trolleys and hollow needles, which is applied in shaft linings, tunnel linings, underground chambers, etc., can solve the problems of high labor intensity, deteriorating construction environment, and low work efficiency, so as to improve traffic capacity, meet ventilation requirements, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment, the utility model is further described.

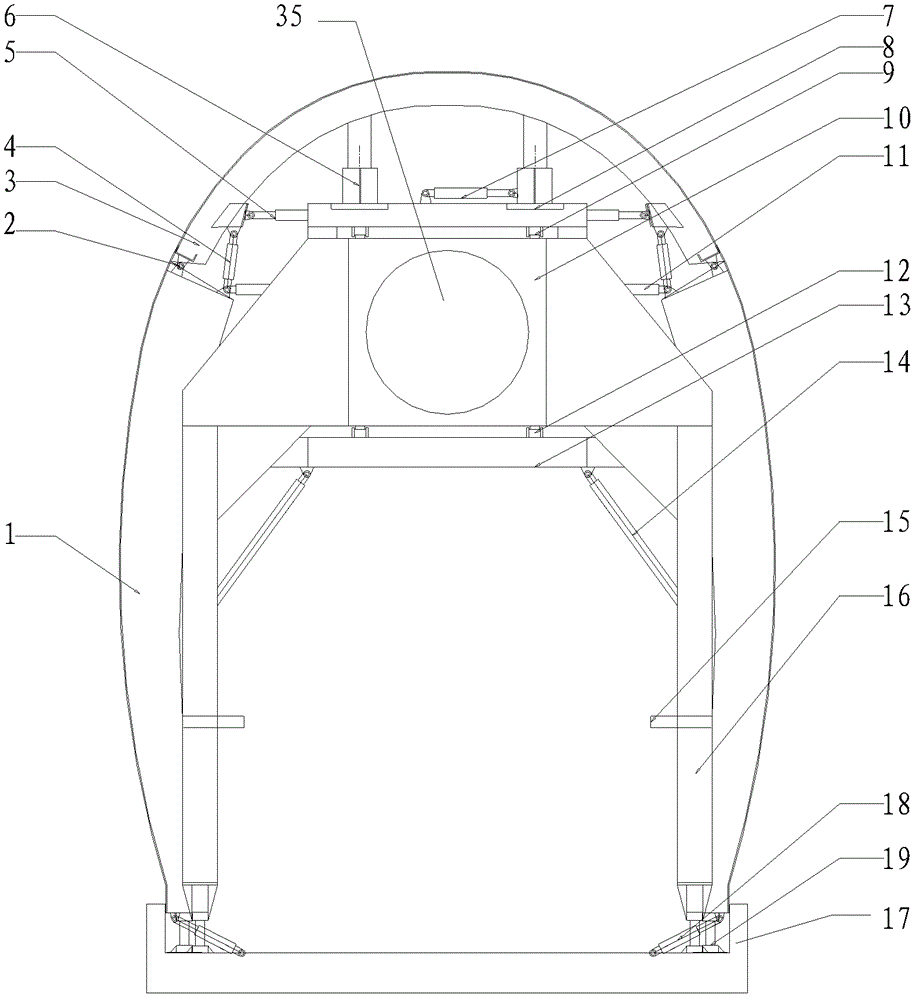

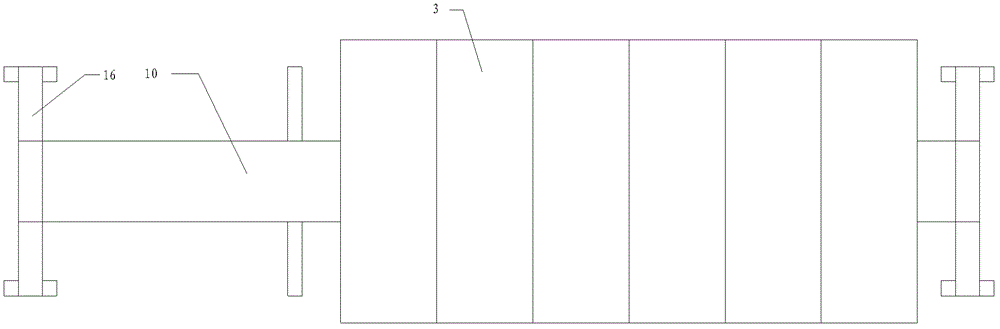

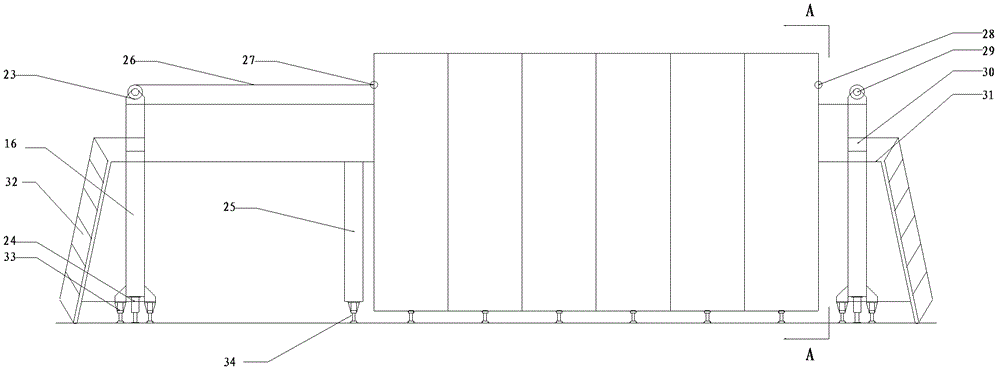

[0026] see figure 1 , figure 2 , image 3 and Figure 4 , the needle beam 10 is a box beam structure with a middle reserved hole 35, which is assembled and welded by steel plates. The two ends of the needle beam 10 are respectively equipped with main legs 16, and the lower end of the main legs 16 is provided with a jacking cylinder 24 With the first load-bearing screw mandrel 33, the hoist 23 is equipped with on one end of the needle beam 10, and the guide pulley 29 is equipped on the other end. There are walking support rollers 12 in sliding contact with the needle beam 10. The formwork system is composed of a top mold 3 and two symmetrically arranged side molds 1. The side mold 1 and the top mold 3 form a ring, and the width of each ring is 1.5-2 meters. In between, the entire trolley is connected by multi-ring formwork through bolts to form a whole a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com