System and method for optimally controlling air compressor load

A load optimization control and air compressor technology, applied in pump control, chemical industry, mechanical equipment, etc., can solve problems such as poor system stability accuracy, dynamic quality, and unsatisfactory control effects, to eliminate adverse effects and improve control accuracy. and dynamic quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

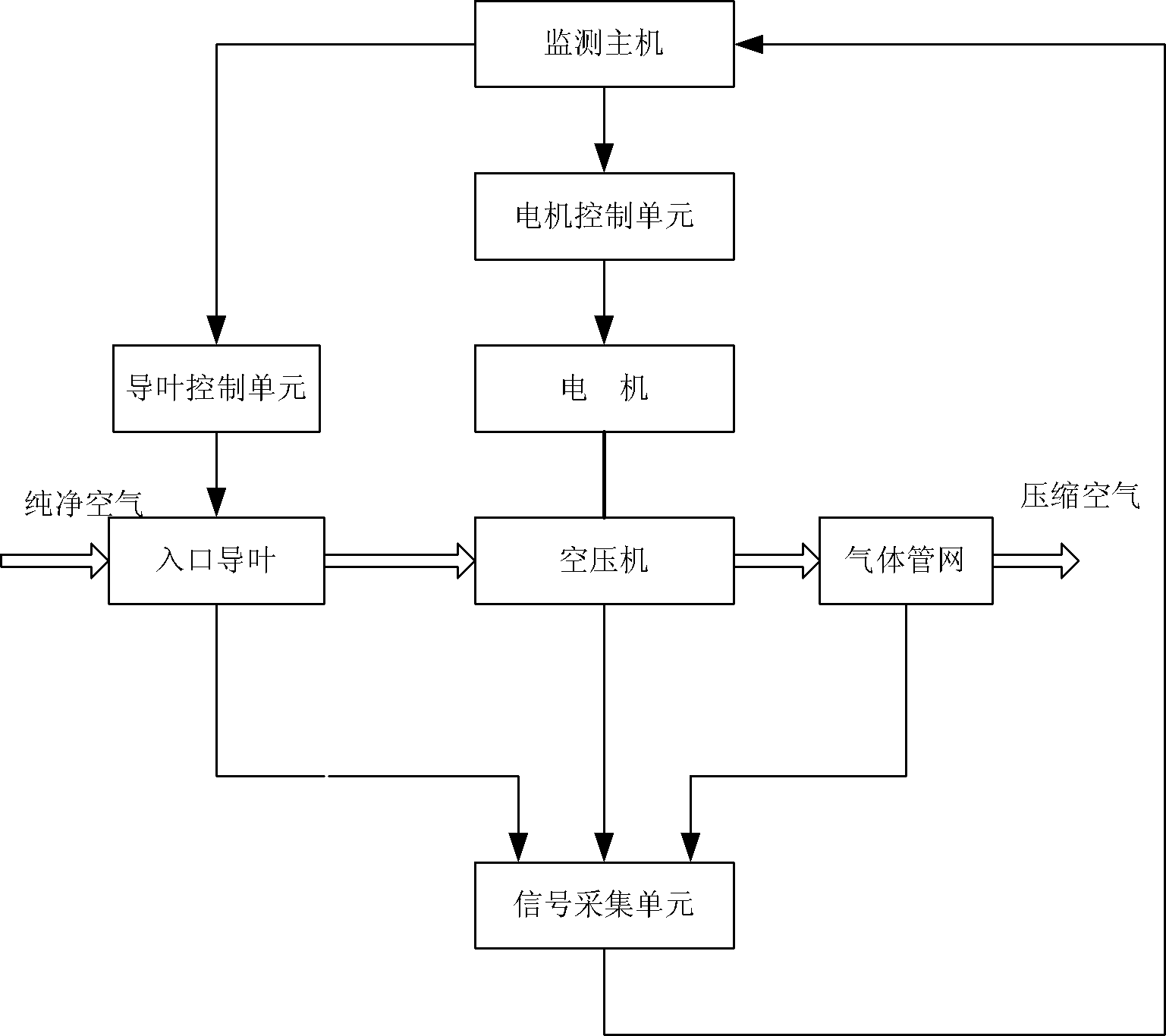

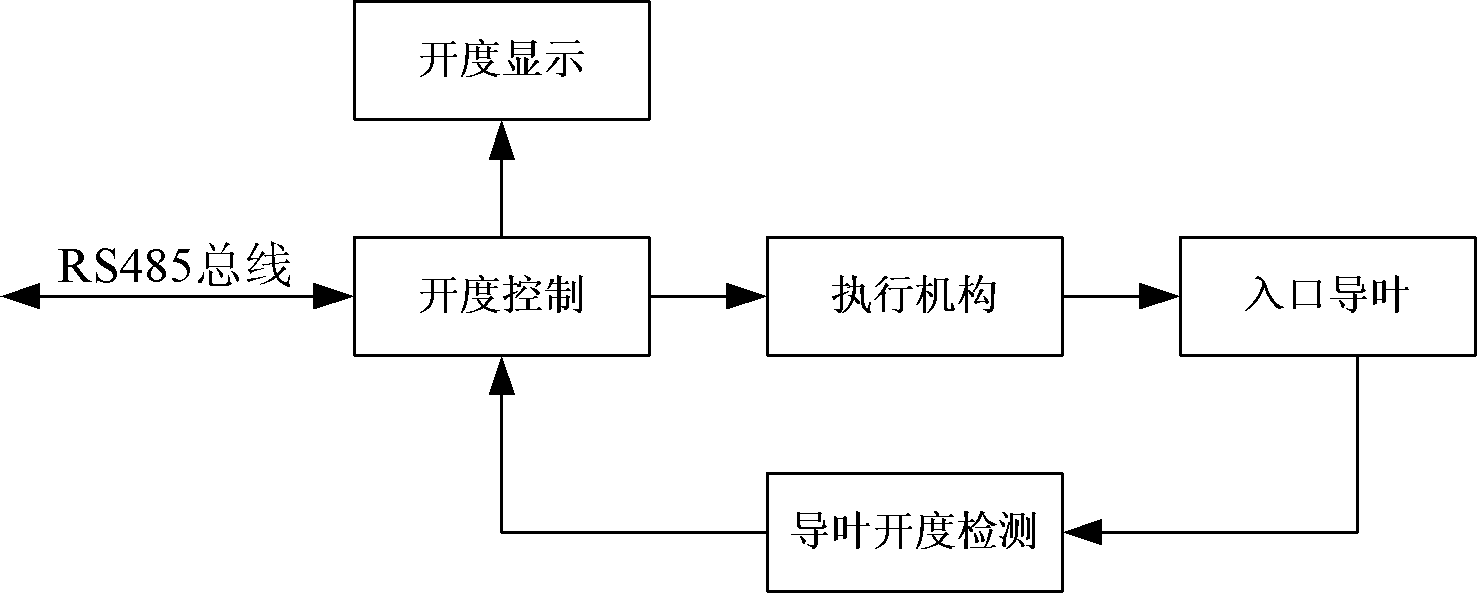

[0023] Such as figure 1 As shown, the air compressor load optimization control system of the present invention is composed of a monitoring host, a signal acquisition unit, a guide vane control unit and a motor control unit.

[0024] The monitoring host is the central control module of the air compressor load optimization control system, using an industrial control computer, the CPU is celon1.6GHz, 512M memory, 80G hard disk, two 485 communication interfaces, runs the windows operating system, and is embedded with c programming language Air compressor load optimization control method; connect with the signal acquisition unit by 485 interface, send control commands, and receive collected data; also connect with motor control unit by 485 interface, send optimization control commands, and adjust motor operation status.

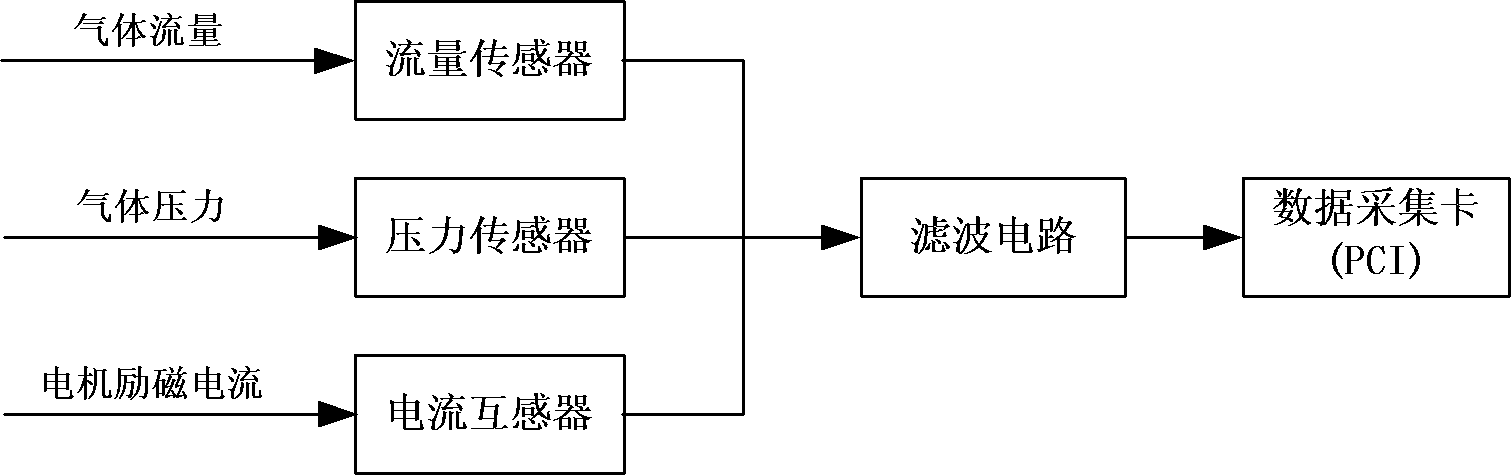

[0025] The signal acquisition unit is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com