High-temperature tail gas quenching reaction tower of refuse combustion furnace

A waste incinerator and reaction tower technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the wear and tear of the lime slurry conveying and spraying system, the scaling and blockage of the reaction tower and flue, and the inability to prevent the formation of dioxin and other problems, to achieve the effect of easy operation and maintenance, avoid scaling and clogging, and reduce the generation of dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

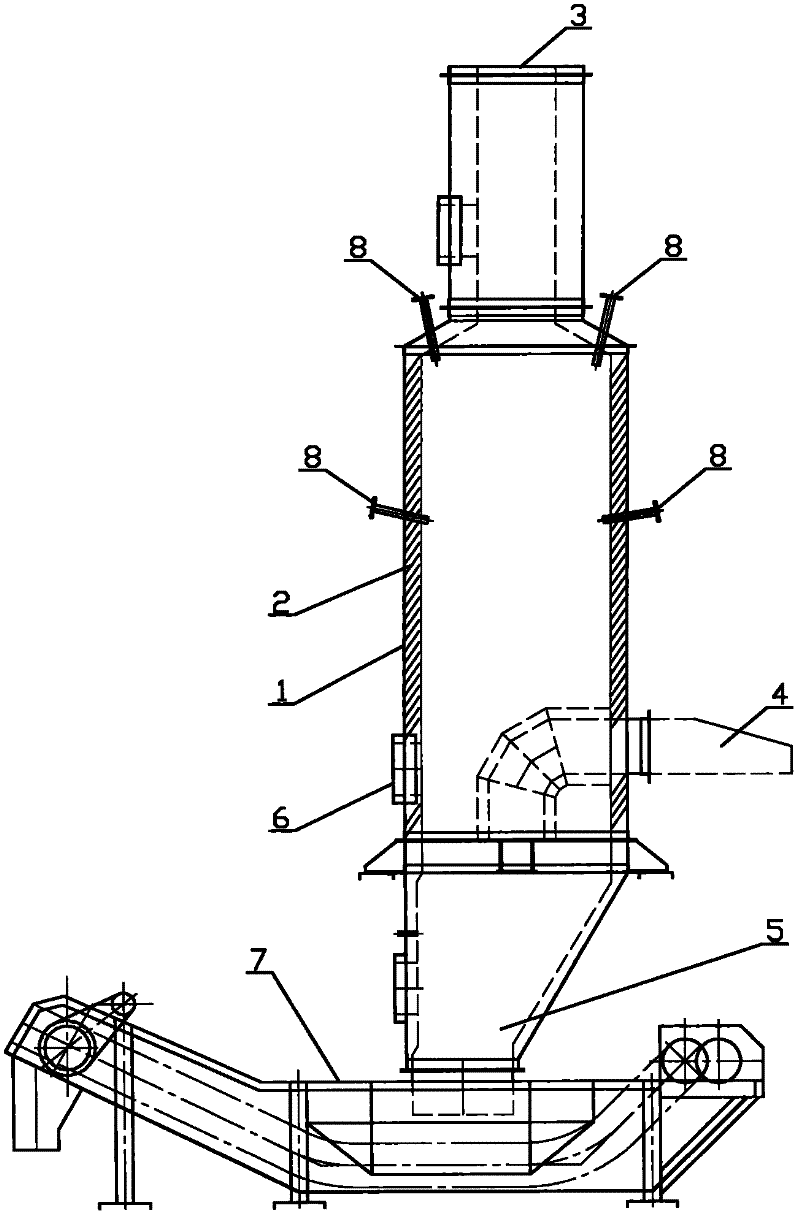

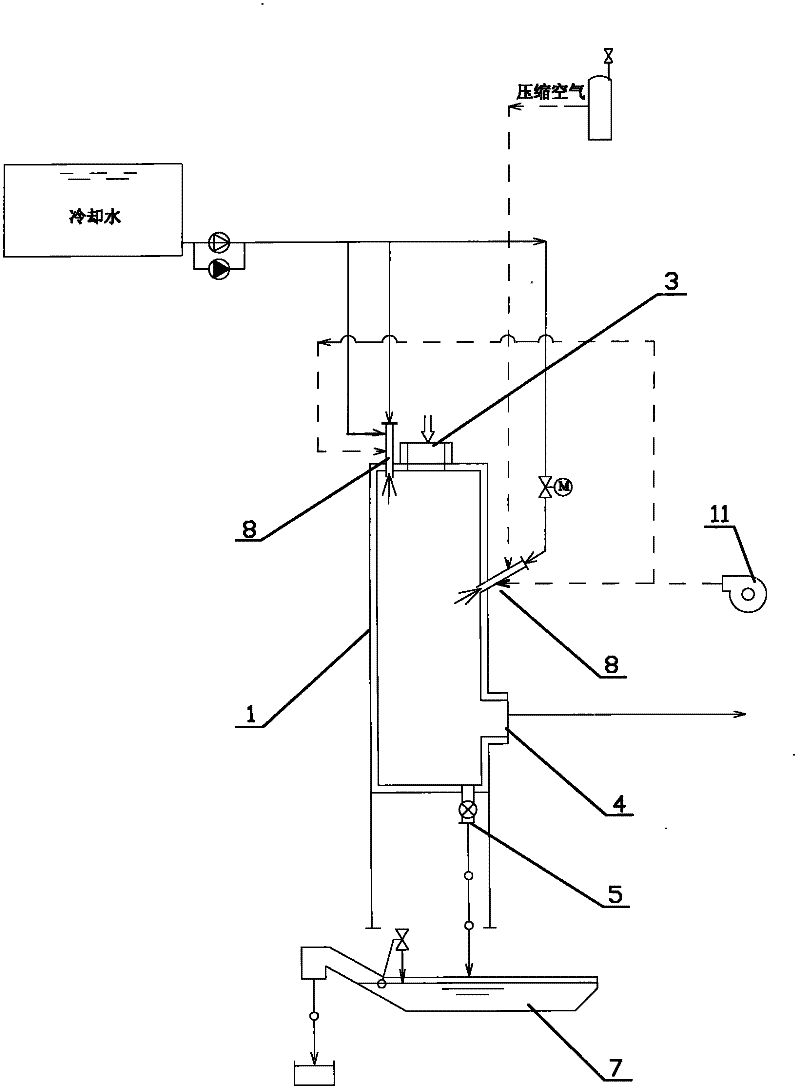

[0011] Depend on figure 1 It can be seen that the high-temperature tail gas quenching reaction tower of the waste incinerator of the present invention includes a tower body 1, the inner wall of the tower is provided with a corrosion-resistant and fire-resistant layer 2, the top of the tower body 1 is provided with a high-temperature tail gas inlet 3, the bottom is provided with a tail gas outlet 4, and the bottom is provided with an exhaust gas outlet. Ash port 5 and manhole 6, ash discharge port 5 leads to ash discharge machine 7. Depending on the size of the tower body, one or more cooling water sprayers 8 are inserted into the top and middle upper part of the tower body 1 . In order to achieve the best spray effect, the cooling water sprayer 8 in the middle and upper part of the tower body 1 is downward and forms an angle of 30° with the axis of the tower body 1 .

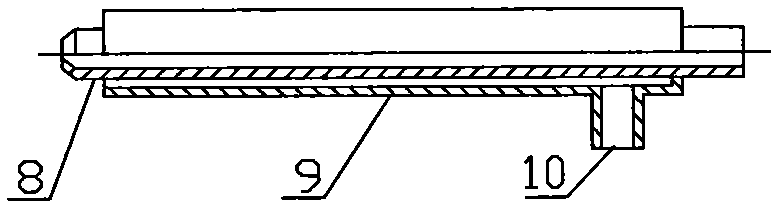

[0012] see figure 2 In order to prevent the acid gas in the tail gas from corroding the cooling water spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com