Photovoltaic terminal box

A volt junction box and box cover technology, applied in the field of photovoltaic power generation, can solve problems such as difficulty in achieving heat dissipation, wasting power resources, and increasing the thickness and volume of photovoltaic junction boxes, so as to achieve heat reduction and rapid heat transfer, and improve deformation resistance Ability, not easy to miss the installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

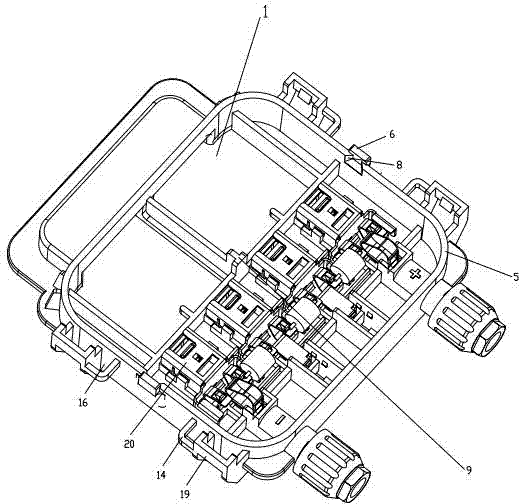

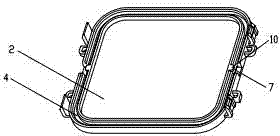

[0027] like Figure 1 to Figure 3 As shown, the present invention includes a base 1 , a box cover 2 and a sealing ring 3 . like figure 2 As shown, the periphery of the box cover 2 is provided with an annular groove 4 , and above the annular groove 4 are provided two opposite cover blocks 10 . image 3 The sealing ring 3 in the figure is placed in the annular groove 4 of the box cover 2 in Figure 2, and is wrapped by the cover block 10 of the box cover 2.

[0028] figure 1 edge 5 of middle base 1 and figure 2 The annular groove 4 of the middle box cover 2 cooperates to realize the extrusion up and down of the sealing ring 3 . figure 1 Both sides of the middle base 1 are respectively provided with outer protrusions 6 , and the two outer protrusions 6 are alternately connected with the edge 5 of the base 1 through hypotenuses 8 . figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com