Electric flocculation device for industrialized microalgae separation and collection

An electro-flocculation and micro-algae technology, applied in the methods of stress-stimulated microbial growth, biochemical instruments, biochemical equipment and methods, etc. quality, improve the effect of electroflocculation, and the effect of high electroflocculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

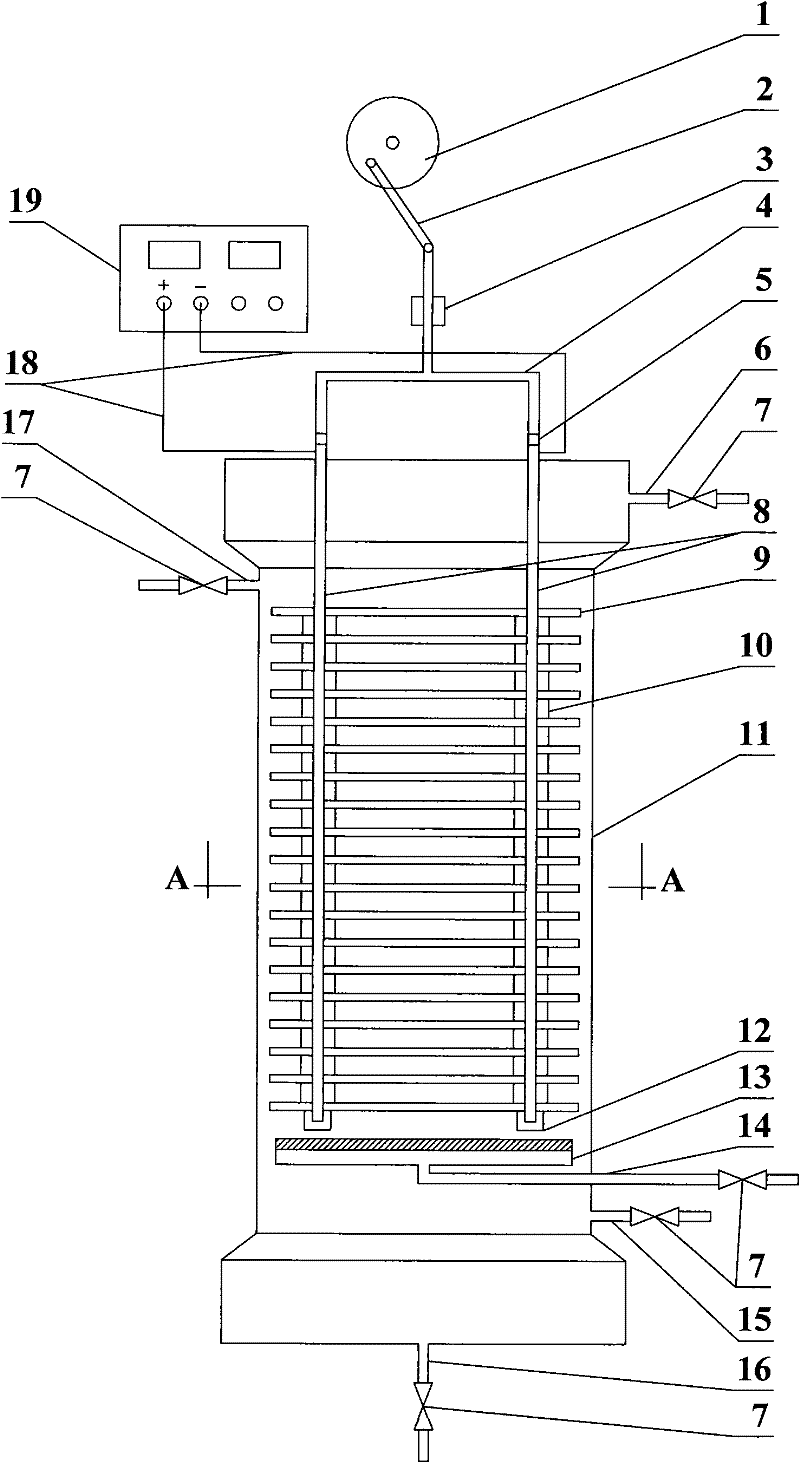

[0050] Embodiment 1: Separation and collection of algal body in botrytis culture fluid

[0051] In the device of the present invention, the separation and collection of algal bodies in the botrytis culture solution is carried out. The botrytis culture liquid enters the tower body through the feed liquid inlet 17, and then electrocoagulation is carried out to separate the algae bodies during the downward movement. The liquid outlet 15 is discharged; the algal body floats to the surface of the liquid under the effect of rising gas while flocculating and continuously gathers, and then overflows and collects from the algal body outlet 6; the flow rate ratio of the feed liquid inlet 17 and the feed liquid outlet 15 is 1: 0.95. During the continuous separation and collection process, samples were taken at the feed liquid outlet 15 to measure the biomass of microalgae in the clear liquid, and the recovery rate of the botrytis algae body was 98.5%.

Embodiment 2

[0052] Embodiment 2: Separation and collection of algal body in chlorella culture fluid

[0053] In the device of the present invention, the separation and collection of algal bodies in the chlorella culture solution is carried out. The chlorella culture solution enters the tower body from the feed liquid inlet 17, and then electrocoagulation is carried out to separate the algae bodies during the downward movement, and the clear liquid It is discharged from the feed liquid outlet 15; while the algae are flocculated, they float to the surface of the liquid under the action of the rising gas and gather continuously, and then overflow and collect from the algae outlet 6; the flow rate ratio between the feed liquid inlet 17 and the feed liquid outlet 15 is 1:0.85. During the continuous separation and collection process, samples were taken at feed liquid outlet 15 to measure the biomass of microalgae in the clear liquid, and the recovery rate of algae body of chlorella was 98.9%. ...

Embodiment 3

[0054] Embodiment 3: Separation and collection of algal body in spirulina culture fluid

[0055] In the device of the present invention, the separation and collection of algae bodies in the spirulina culture solution is carried out. The spirulina culture solution enters the tower body from the feed liquid inlet 17, and then electrocoagulation is carried out to separate the algae bodies during the downward movement. The liquid outlet 15 is discharged; the algal body floats to the surface of the liquid under the effect of rising gas while flocculating and continuously gathers, and then overflows and collects from the algal body outlet 6; the flow rate ratio of the feed liquid inlet 17 and the feed liquid outlet 15 is 1: 0.9. During the continuous separation and collection process, samples were taken at feed liquid outlet 15 to measure the biomass of microalgae in the clear liquid, and the algae body recovery rate of spirulina was 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com