Design method for main runner of fuel cell stack and fuel cell stack structure

A fuel cell stack and fuel cell unit technology, which is applied to fuel cell components, fuel cells, fuel cell grouping, etc., can solve problems such as the inability to achieve the best power generation efficiency, the difficulty in shunting fuel gas, and the difficulty in controlling power generation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

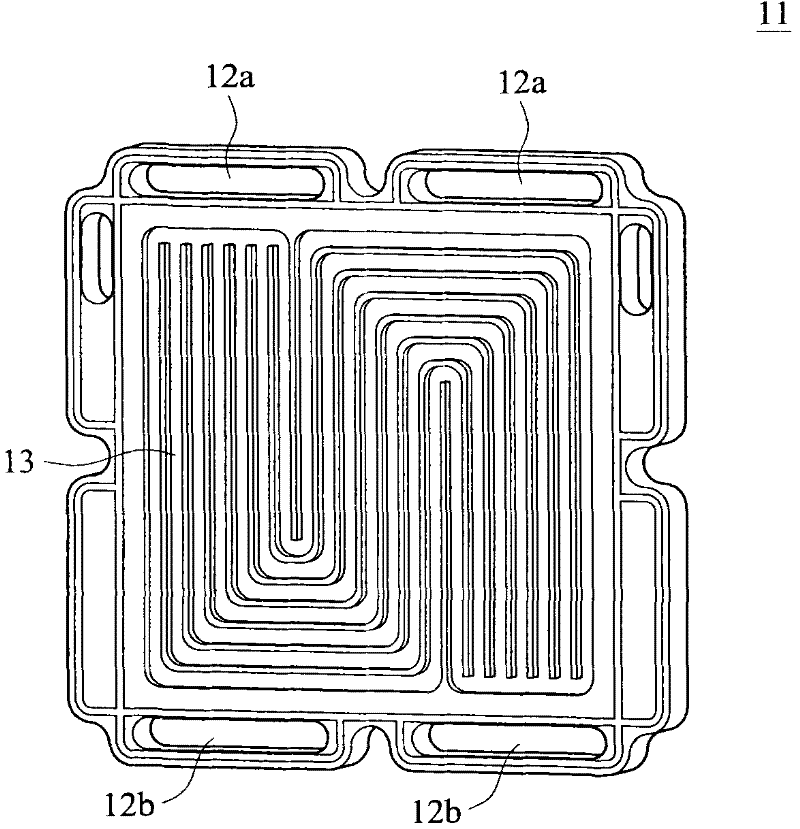

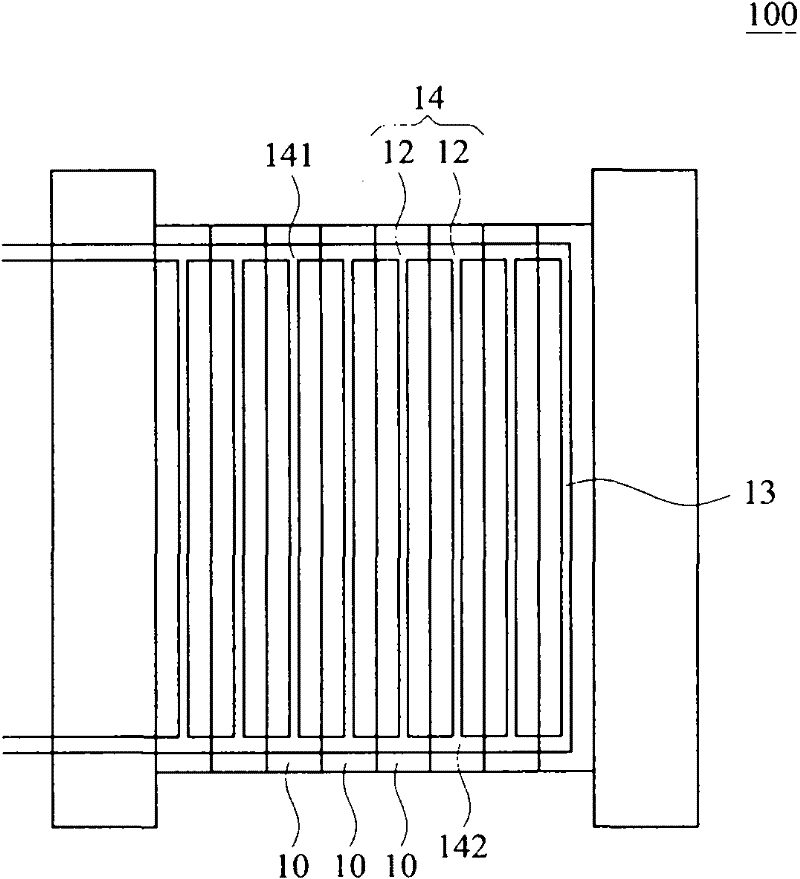

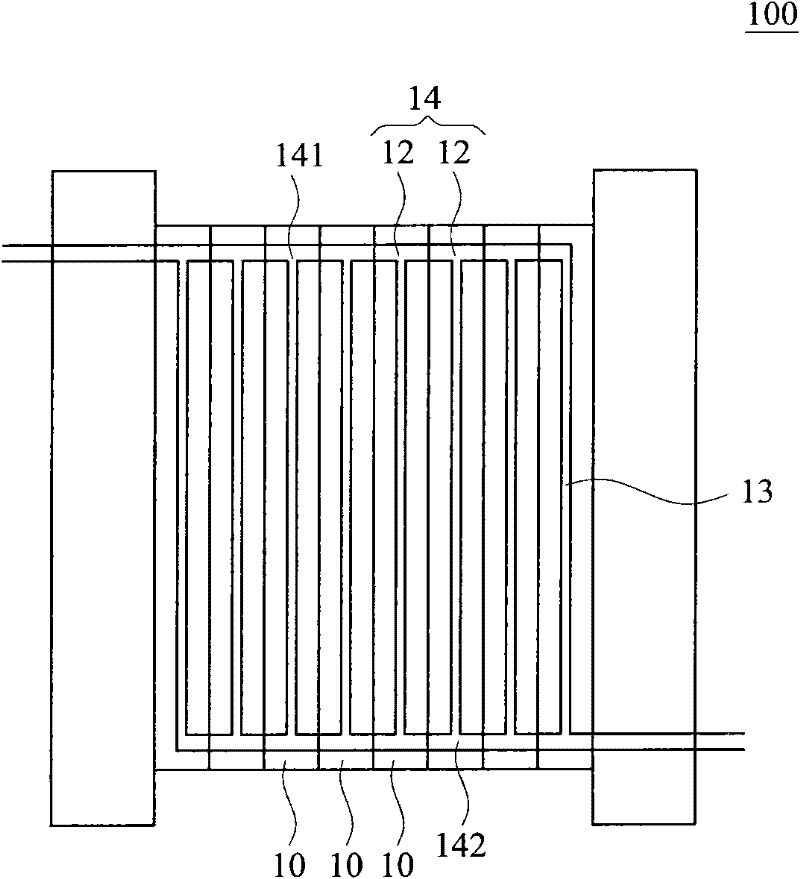

[0038] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the method for designing the main channel of the fuel cell stack and the structure of the fuel cell stack according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Embodiments, methods, steps, features and effects thereof are described in detail below.

[0039] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the drawings. Through the description of the specific implementation mode, when the technical means and functions adopted by the present invention to achieve the predetermined purpose can be obtained a deeper and more specific understanding, but the accompanying drawings are only for reference and des...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap