Integrated warm gas desulfurization and gas shift for cleanup of gaseous streams

A material flow, gas technology, applied in the field of integrated process, can solve the problem of inability to remove sulfur compounds and solid particle pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

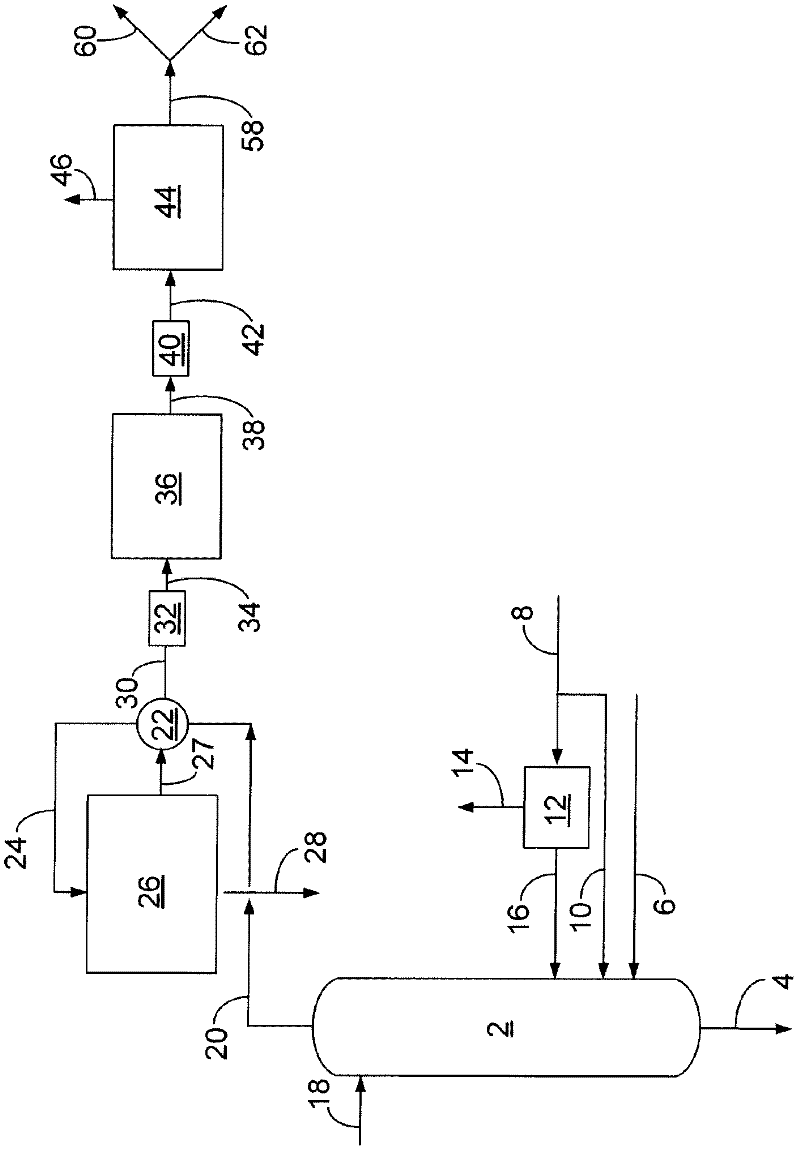

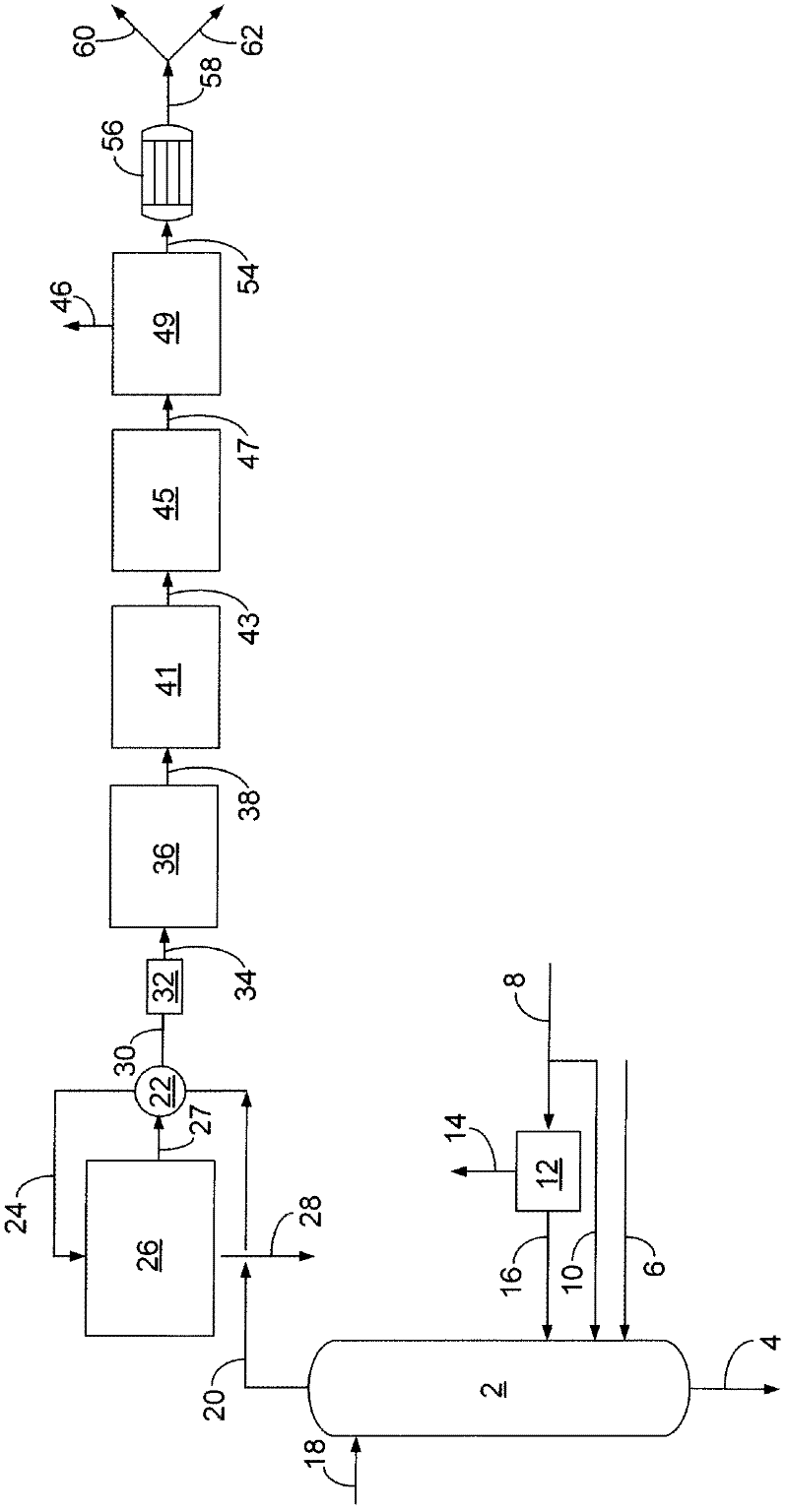

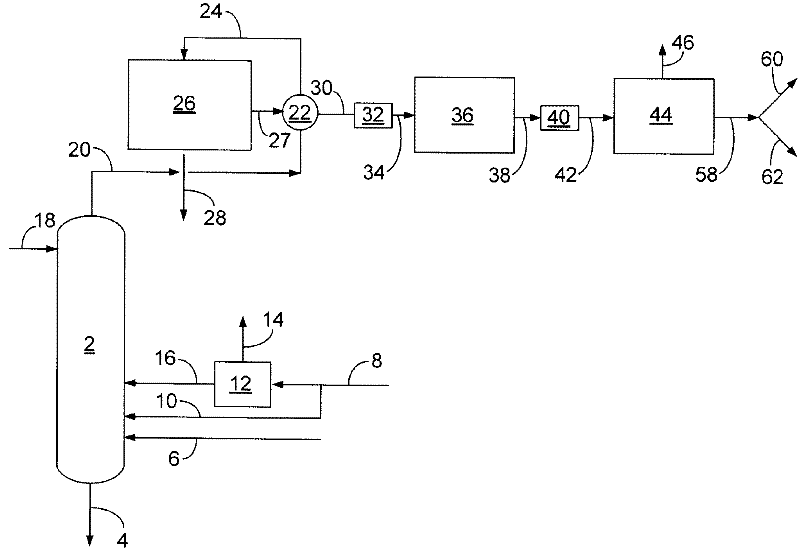

[0011] The present invention includes complete desulfurization (H 2 The integration of S and COS removal) method and CO-rotation process method, which uses solid catalysts at 250°C to 550°C in order to maximize the production of hydrogen from fuel gas and thereby promote clean enrichment CO 2 The capture. CO 2 The stream can be captured and concentrated downstream of the integrated desulfurization and CO rotation unit, which uses a physical solvent method ( figure 1 ), or alternatively use high temperature CO 2 Absorbent ( figure 2 ). This concept represents the next generation of syngas processing and applications, not only in the power generation industry but also in the production of chemicals and fuels.

[0012] The present invention includes COS hydrolysis and hydrogenation process methods, and H 2 S removal method, and integration with CO rotation process method, which uses solid catalyst at 250°C to 550°C in order to maximize the production of hydrogen from fuel gas, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com