Epitaxial growth method of InGaN quantum dot and single photon source obtained thereby

A technology of epitaxial growth and growth method, which is applied in the field of single photon source, can solve the problems of large randomness of InGaN quantum dots, difficult control of lateral size and density, unsuitability for single photon source, etc., to achieve suitable for large-scale application, mild conditions, The effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

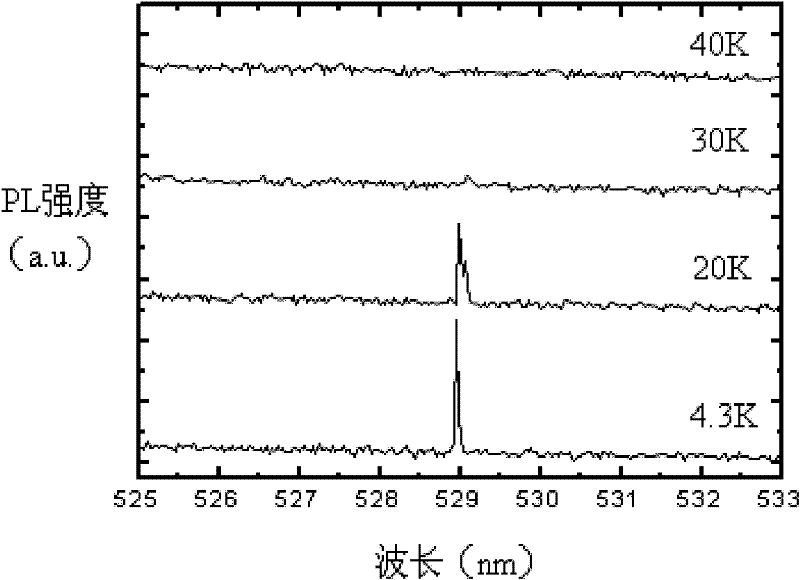

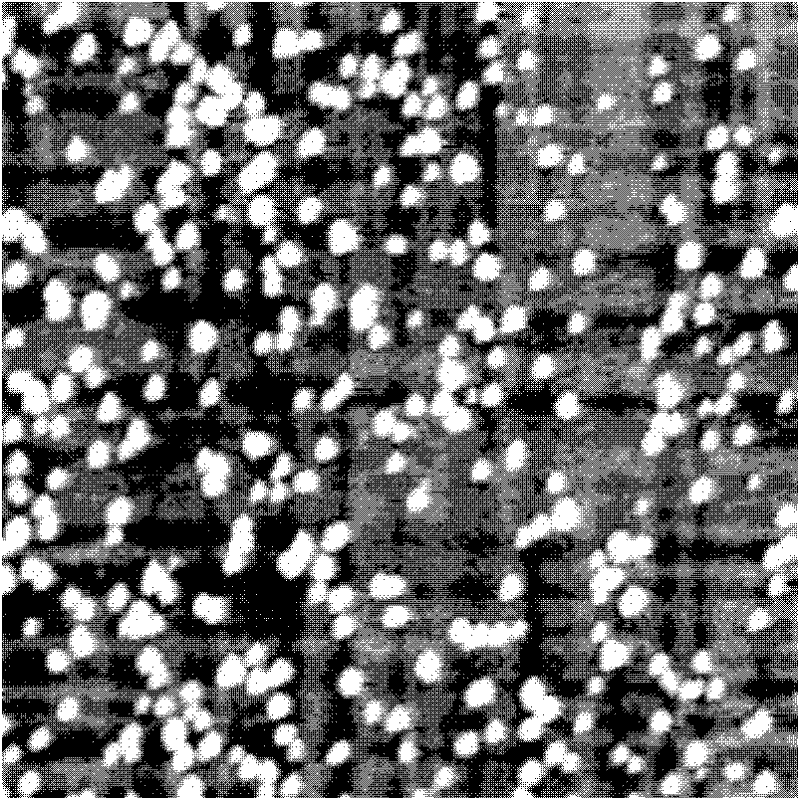

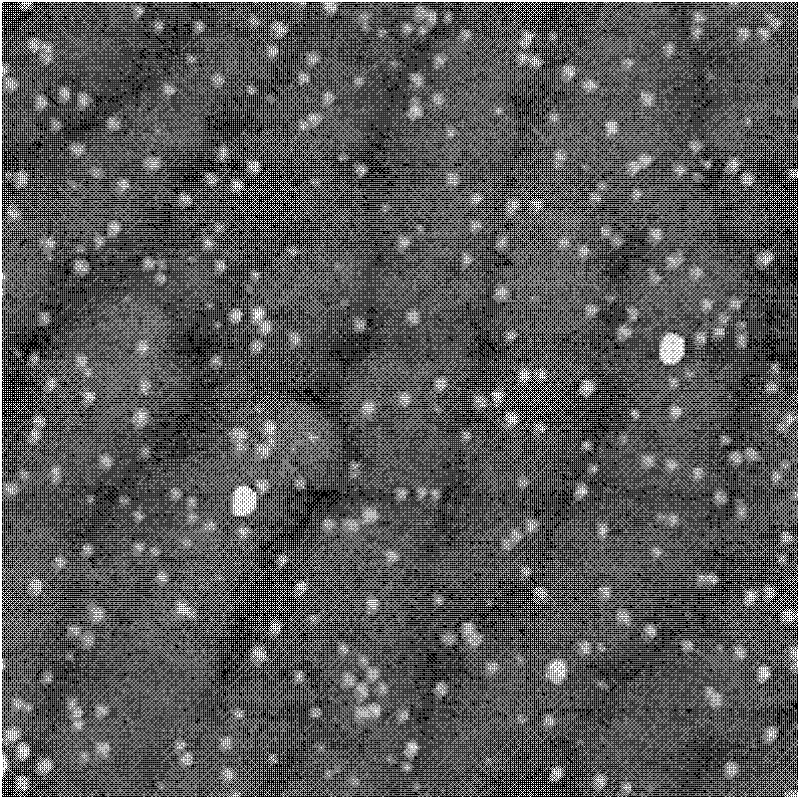

[0031] Using MOCVD to grow low-density InGaN quantum dots in the low-temperature GaN insertion layer, the epitaxy sequence is as follows Figure 4 As shown, its specific growth process is:

[0032] 1. The carrier gas is H 2 , the sapphire substrate at H 2 Cleaning was carried out for 10 minutes under ambient conditions, the temperature was 1060° C., and the pressure of the reaction chamber was 200 mbar.

[0033] 2. The carrier gas is H 2 , a 30nm-thick GaN buffer layer was grown on a sapphire substrate at a temperature of 530°C and a reaction chamber pressure of 400mbar.

[0034] 3. The carrier gas is H 2 , a GaN bulk material with a thickness of 2 μm was grown on the GaN buffer layer at a temperature of 1040° C. and a reaction chamber pressure of 400 mbar.

[0035] 4. Switch the carrier gas to N 2 , grow a 20nm-thick GaN insertion layer on the GaN bulk material at a temperature of 650°C and a reaction chamber pressure of 400mbar.

[0036] 5. The carrier gas is N 2 , I...

Embodiment 2

[0040]Using MOCVD to grow low-density InGaN quantum dots in the low-temperature GaN insertion layer, the epitaxy sequence is as follows Figure 4 As shown, its specific growth process is:

[0041] 1. The carrier gas is H 2 , SiC substrate in H 2 Cleaning was carried out for 10 minutes under ambient conditions, the temperature was 1200° C., and the pressure of the reaction chamber was 400 mbar.

[0042] 2. The carrier gas is H 2 , a 20nm-thick AlN buffer layer was grown on a SiC substrate at a temperature of 1200°C and a reaction chamber pressure of 100mbar.

[0043] 3. The carrier gas is H 2 , a 2000nm thick GaN bulk material was grown on the AlN buffer layer at a temperature of 1100°C and a reaction chamber pressure of 400mbar.

[0044] 4. Switch the carrier gas to N 2 , a 25nm-thick GaN insertion layer was grown on the GaN bulk material at a temperature of 765°C and a reaction chamber pressure of 400mbar.

[0045] 5. The carrier gas is N 2 , grow InGaN quantum dots o...

Embodiment 3

[0049] Using MOCVD to grow multi-layer low-density InGaN quantum dots in the low-temperature GaN insertion layer to form a single photon source of multi-layer quantum dot mechanism, the epitaxial growth sequence is as follows Figure 5 As shown, its specific growth process is:

[0050] 1. The carrier gas is H 2 , the sapphire substrate at H 2 Cleaning was carried out for 10 minutes under ambient conditions, the temperature was 1060° C., and the pressure of the reaction chamber was 200 mbar.

[0051] 2. The carrier gas is H 2 , a 50nm-thick AlN buffer layer was grown on a sapphire substrate at a temperature of 400°C and a reaction chamber pressure of 400mbar.

[0052] 3. The carrier gas is H 2 , a 5 μm thick GaN bulk material was grown on the AlN buffer layer at a temperature of 1040° C. and a reaction chamber pressure of 400 mbar.

[0053] 4. Switch the carrier gas to N 2 , a 15nm-thick GaN insertion layer was grown on the GaN bulk material at a temperature of 650°C and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com