Method for extracting fish oil from waste sleeve-fish liver

A technology of fish oil and liver, which is applied in the field of extracting fish oil from discarded squid liver, can solve problems that have not been paid attention to and have not been described in detail, and achieve the effects of easy process control, increased added value, and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with embodiment the present invention is described in further detail.

[0036] 1. Extract fish oil from squid liver

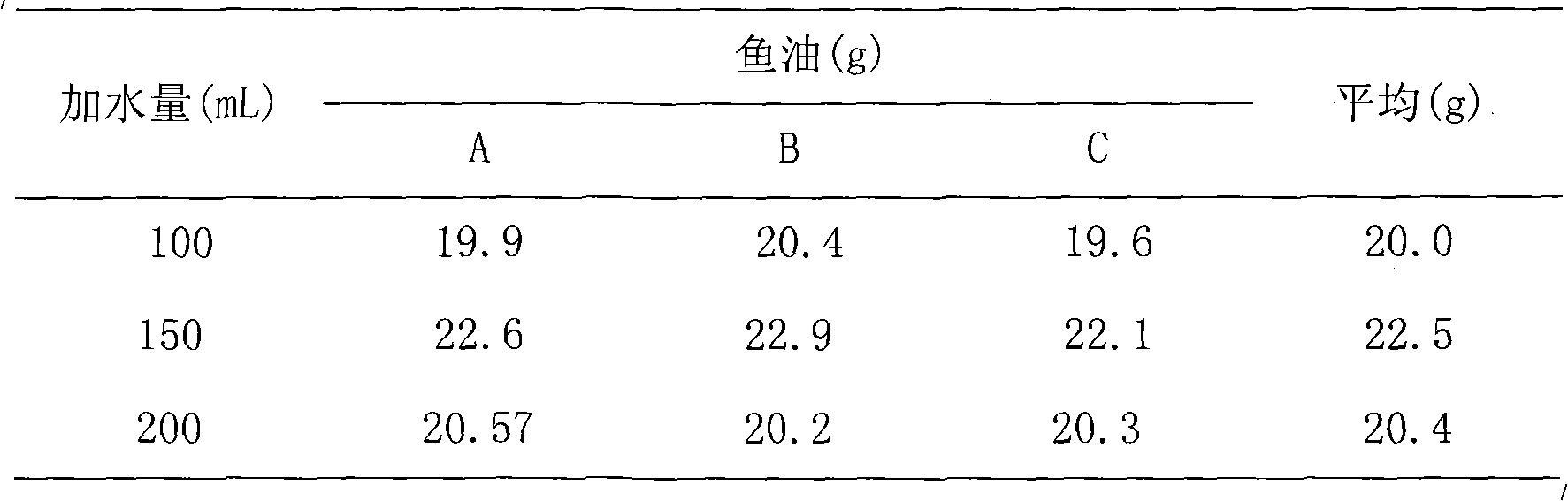

[0037] Take 100g squid liver, add water according to the mass ratio of 1:1, 1:1.5, 1:2 respectively, stir evenly, fill with nitrogen for 10min, and add 0.2g of L-ascorbic acid-6-palmitate to prevent oxidation, put in In a pressure cooker, high temperature and high pressure (121°C, 0.5Mpa), process for 20min, take it out and centrifuge at 5000rpm / min for 30min, the oil floating in the upper layer is the crude fish oil.

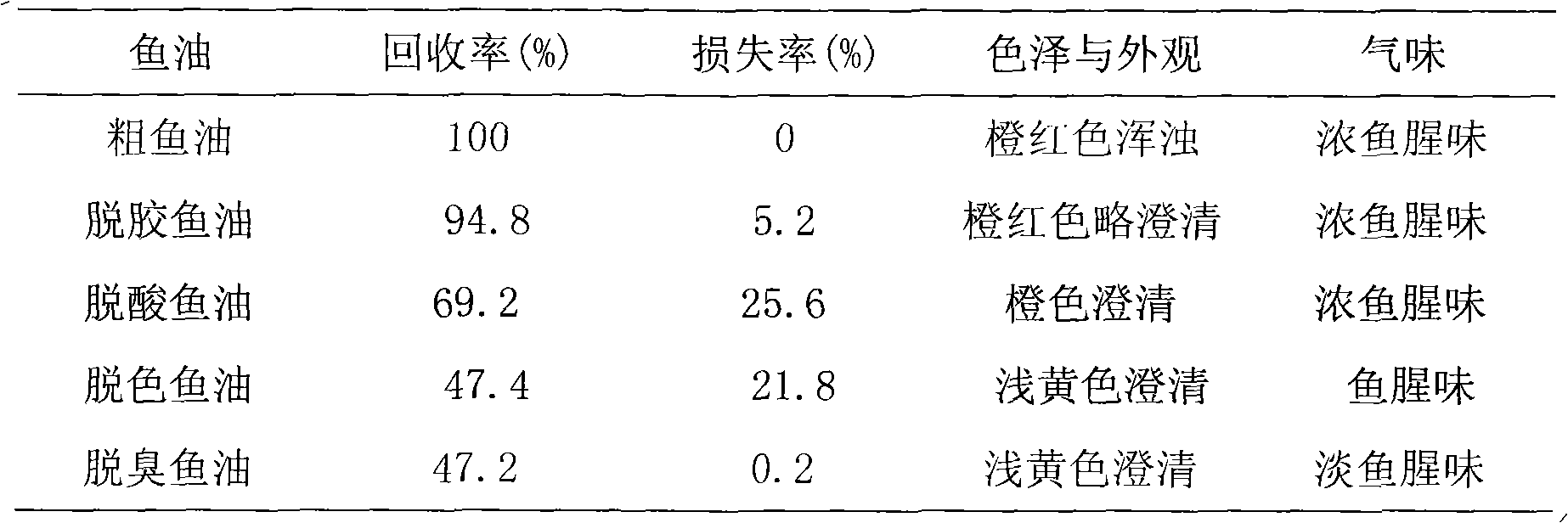

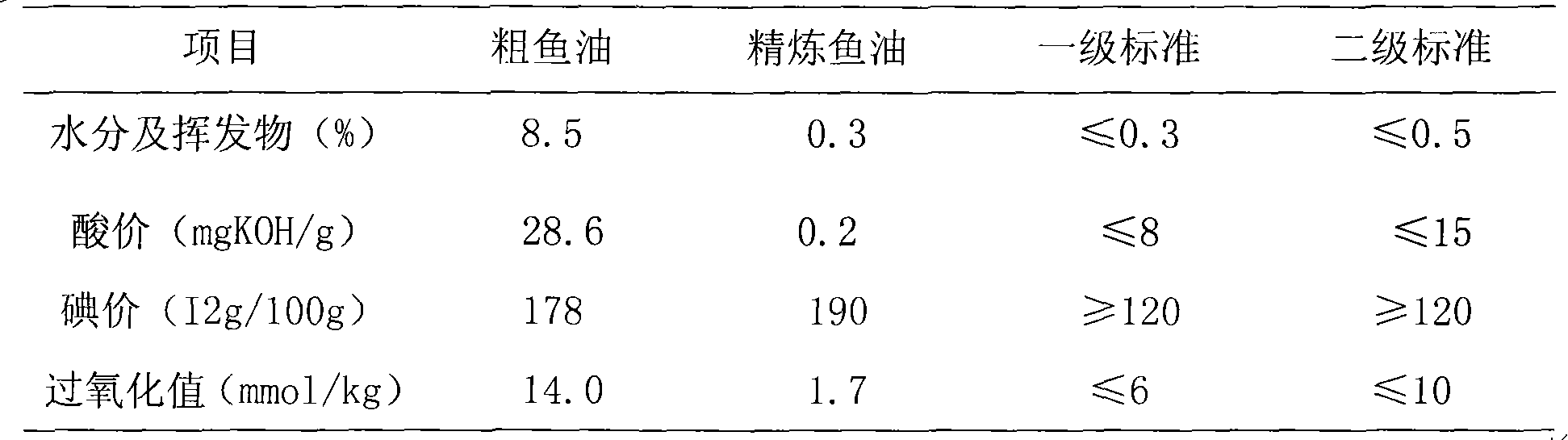

[0038] 2. Refining of fish oil

[0039] a, degumming: take a certain amount of crude fish oil, heat 80°C in a water bath, and constantly stir, then slowly add phosphoric acid (80% by volume) accounting for 1% of the volume of fish oil, stir evenly, and heat at 80°C for 1min, Then centrifuge at 5000rpm / min for 20min, and the oil floating in the upper layer is the degummed fish oil.

[0040] B, deacidification: add N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com