Tungsten/copper gradient material and preparation method thereof

A gradient material and purity technology, applied in the field of material preparation, can solve the problems of limited composition, uneven microstructure, low densification degree, etc., and achieve the effect of continuous gradient distribution of composition, uniform microstructure and high degree of densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing tungsten / copper gradient material, comprising the following steps:

[0036] The experimental raw materials used are: Al powder (purity 98.6%, 100 μm), W powder (purity 99.5%, 2.6-5 μm), Cu 2 O powder (purity 99%, 45 μm).

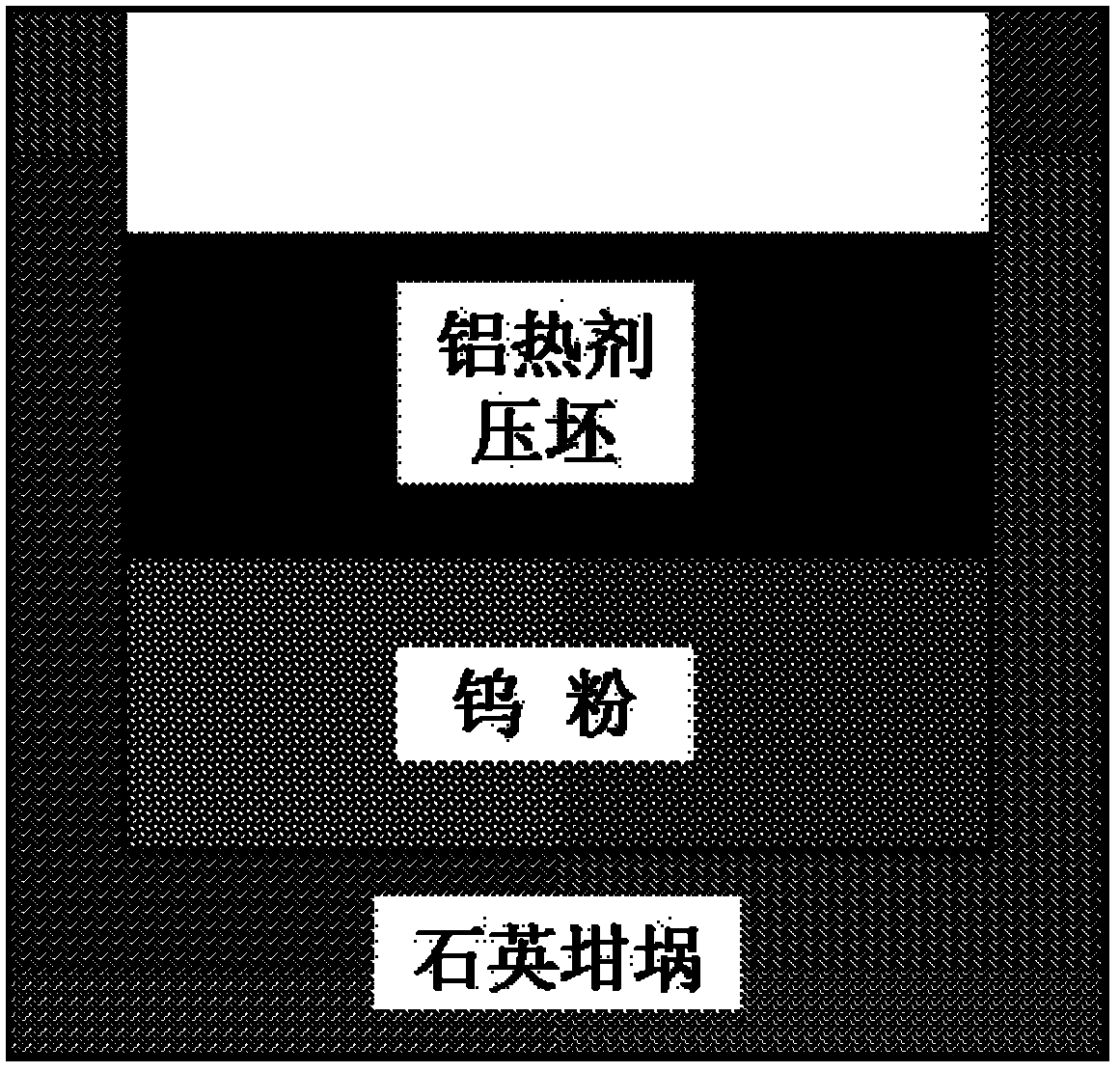

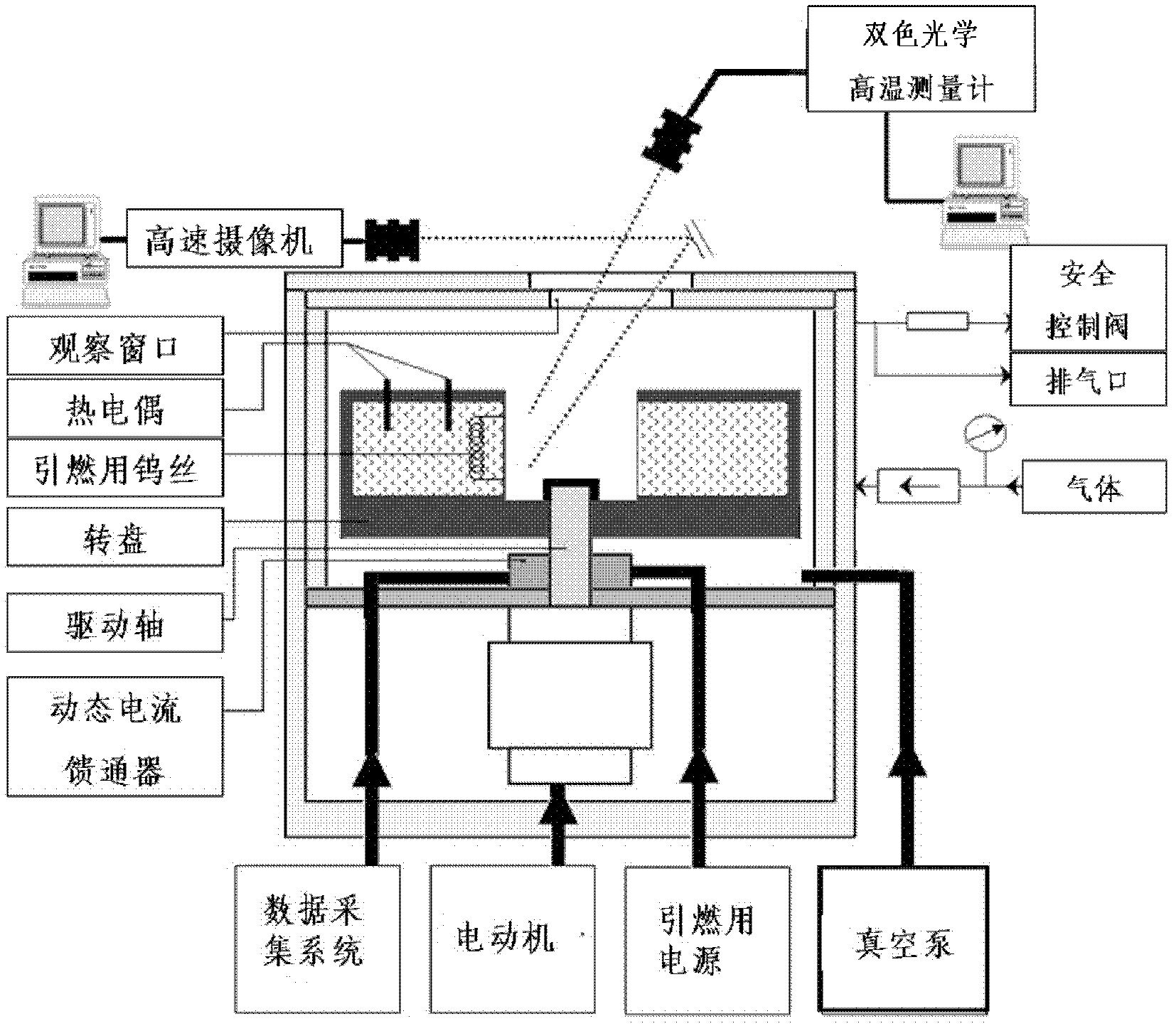

[0037] According to thermite (Al powder and Cu 2 O powder) composition molar ratio n Al : n Cu2O =2:3 to deploy the thermite raw material; then use absolute ethanol as the medium to mechanically activate on a planetary ball mill for 2 hours, then put it into an oven and dry it for 12 hours; put 200g of the dried raw material into a cylindrical steel mold (Φ40mmx80mm ) with a molding pressure of 15 MPa to obtain a thermite compact with a relative density of 50%. Then put the thermite compact into a quartz crucible with 10 mm thick loose tungsten powder, and the thermite compact will press the loose tungsten powder as a whole (such as figure 1 shown), then place the quartz crucible in the stainless steel reactor, and finally ...

Embodiment 2

[0042] A method for preparing tungsten / copper gradient material, comprising the following steps:

[0043] The experimental raw materials used are: Al powder (purity 99.0%, 10 μm), W powder (purity 99.7%, 2 μm), Cu 2 O powder (purity 99.2%, 10 μm).

[0044]According to thermite (Al powder and Cu 2 O powder) composition molar ratio n Al : n Cu2O = 2:3 to prepare thermite raw materials; then use absolute ethanol as the medium to mechanically activate on a planetary ball mill for 0.5 hours, and then put it into an oven at 80°C for 10 hours; put 250g of the dried raw materials into a cylindrical steel Molded in a mold (Φ40mmx80mm), the molding pressure is 15MPa, and pressed for 5min to obtain the thermite compact. Then put the thermite compact into a quartz crucible with 10 mm thick loose tungsten powder, the thermite compact will press the loose tungsten powder as a whole, then place the quartz crucible in a stainless steel reactor, and finally put Install the stainless steel...

Embodiment 3

[0046] A method for preparing tungsten / copper gradient material, comprising the following steps:

[0047] The experimental raw materials used are: Al powder (purity 98.6%, 150 μm), W powder (purity 99.5%, 25 μm), Cu 2 O powder (purity 99.6%, 100 μm).

[0048] According to thermite (Al powder and Cu 2 O powder) composition molar ratio n Al : n Cu2O =2:3 to prepare thermite raw materials; then use absolute ethanol as the medium to mechanically activate on a planetary ball mill for 24 hours, and then put it into an oven at 100°C to dry for 10 hours; put 100g of dried raw materials into a cylindrical steel Molded in a mold (Φ40mmx80mm), the molding pressure is 40MPa, and pressed for 20min to obtain the thermite compact. Then put the thermite compact into a quartz crucible with 10 mm thick loose tungsten powder, the thermite compact will press the loose tungsten powder as a whole, then place the quartz crucible in a stainless steel reactor, and finally put Install the stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com