Self-centering synchronously clamped silicon rod butting machine

A synchronous clamping and self-centering technology, used in fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of scrap silicon rods, complicated processes, scrap cutting and other problems, so as to improve processing efficiency and improve technology. The effect of low requirements, high dimensional accuracy and high geometrical accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

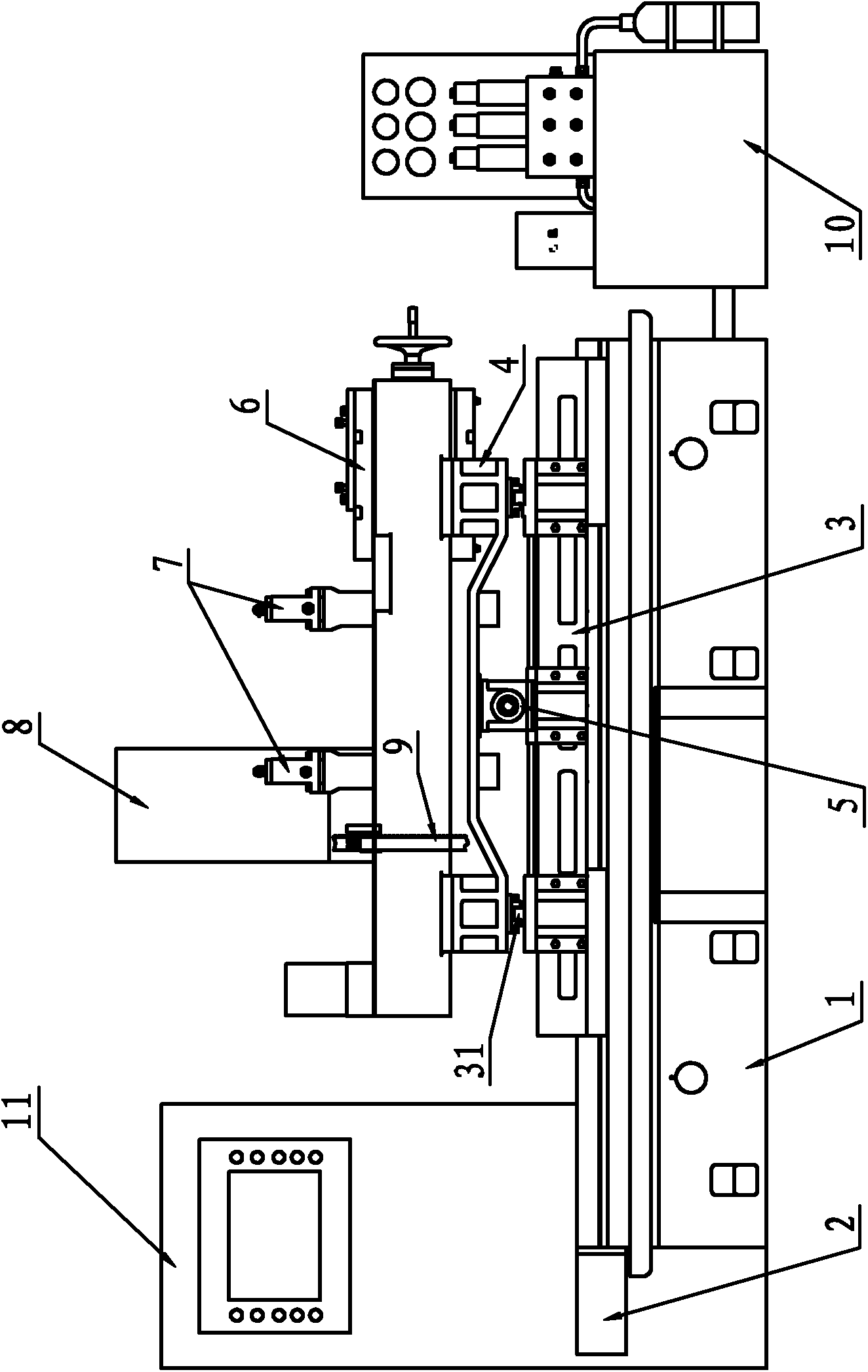

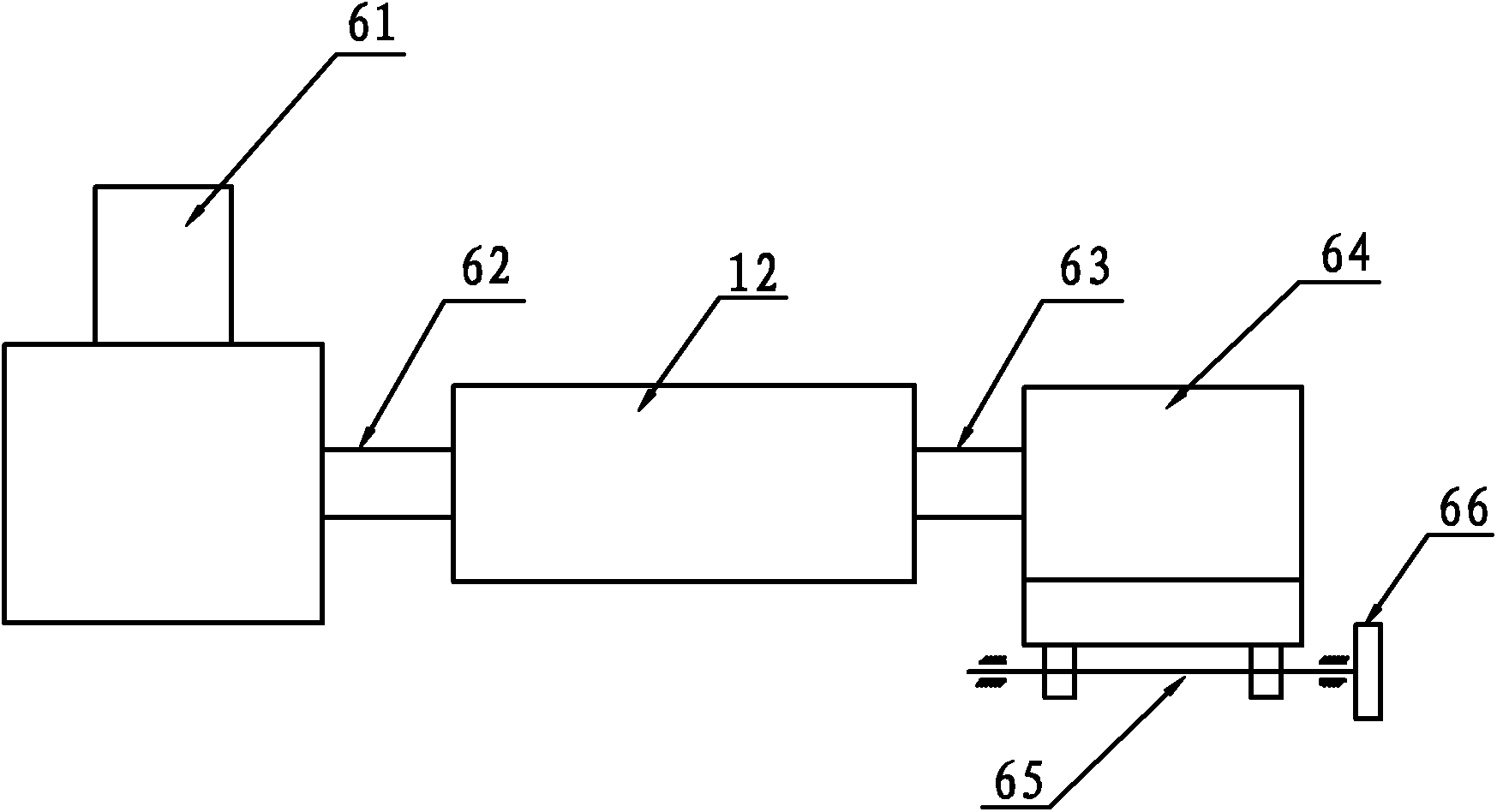

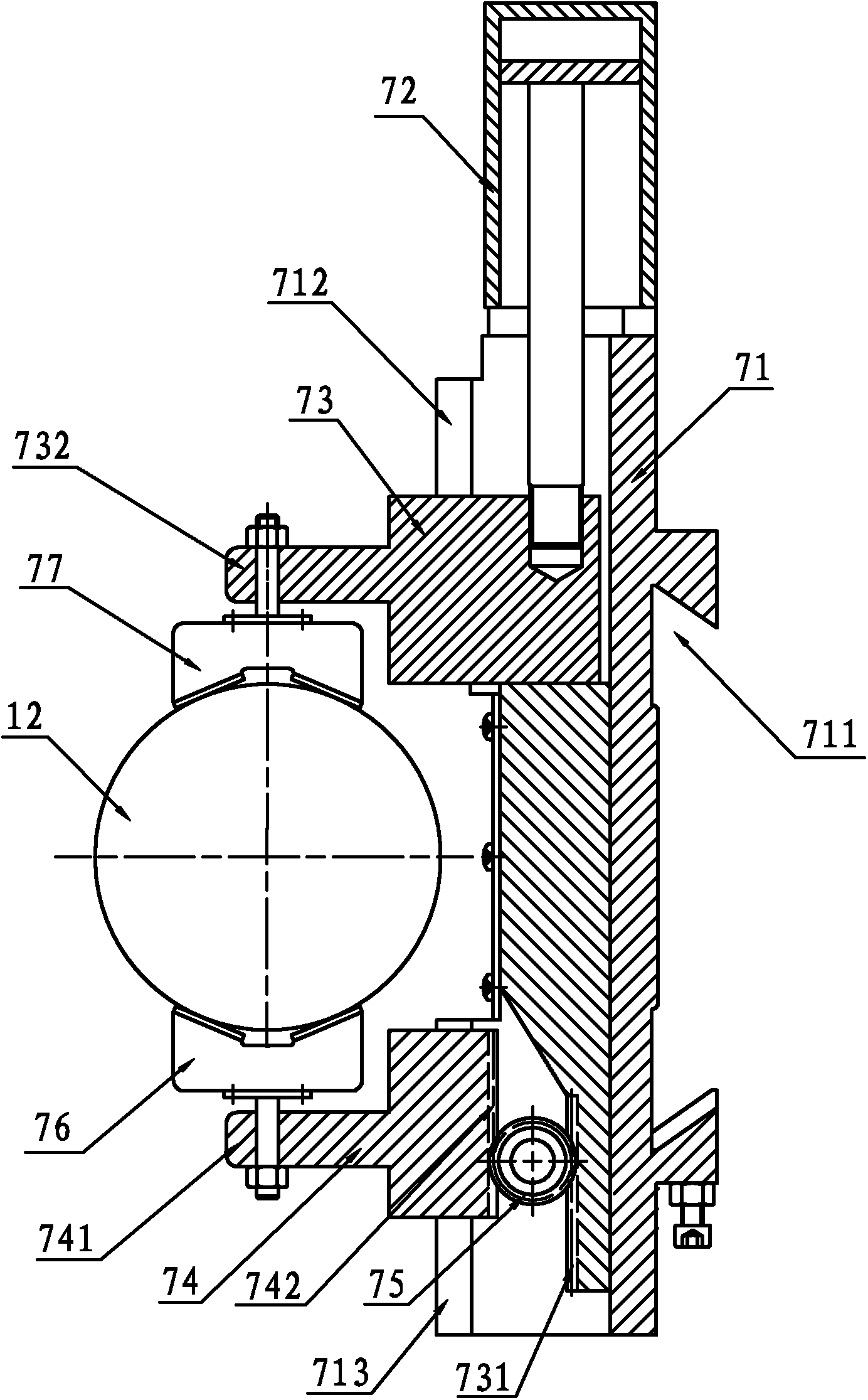

[0023] A self-centering and synchronous clamping silicon rod cutting machine, such as figure 1 As shown, it includes a feed slide base 1, a feed motor 2, a feed slide 3, a longitudinal feed slide 4, a longitudinal feed motor 5, a pressing device 6, a self-centering double support positioning and clamping device 7, a belt Saw side stand 8, saw blade 9, hydraulic station 10 and electric control box 11, feed slide table 3 is installed on feed slide table seat 1, is provided with between feed slide table 3 and feed slide table seat 1 The screw nut linear motion mechanism driven by the motor 2; a longitudinal slide rail 31 is provided on the feed slide table 3, and the longitudinal feed slide table 4 is slidably matched with the longitudinal slide rail 31 on the feed slide table 3; Between the platform 4 and the feed slide 3, there is a screw nut linear motion mechanism driven by the longitudinal feeding motor 5; the pressing device 6 is as figure 2As shown, it includes an electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com