Preparation method of foaming ordered mesoporous carbon integral material with graded tunnel structure

A monolithic material and foam-like technology, which is applied in the field of preparation of foam-like ordered mesoporous carbon monolithic materials with hierarchical pore structure, can solve the problem of uneven distribution of carbon sources, difficulty in controlling the shape and size of bulk silicon templates, and large size of residual solvents. cracks and other problems, to achieve the effect of easy operation, easy amplification, and easy parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare a furfuryl alcohol solution with a mass concentration of 0.05 oxalic acid; prepare a suspension according to the weight ratio of the powdered ordered mesoporous silicon material SBA-15 to the furfuryl alcohol solution of oxalic acid at a weight ratio of 1:10, and stir the suspension for 1 hour; Immerse the fat foam in the obtained suspension for 10 minutes, squeeze out the excess suspension; polymerize and solidify at 180°C for 5 hours to obtain a composite foam, place the above composite foam in a nitrogen atmosphere, and heat it at 0.01°C·min -1 The temperature is raised to 700° C. for carbonization treatment for 1 hour to obtain a composite material of foamy ordered mesoporous silicon material and carbon. The composite material was soaked in 48% hydrofluoric acid for 24 hours, washed until neutral, and dried to obtain a foamy ordered mesoporous carbon monolith.

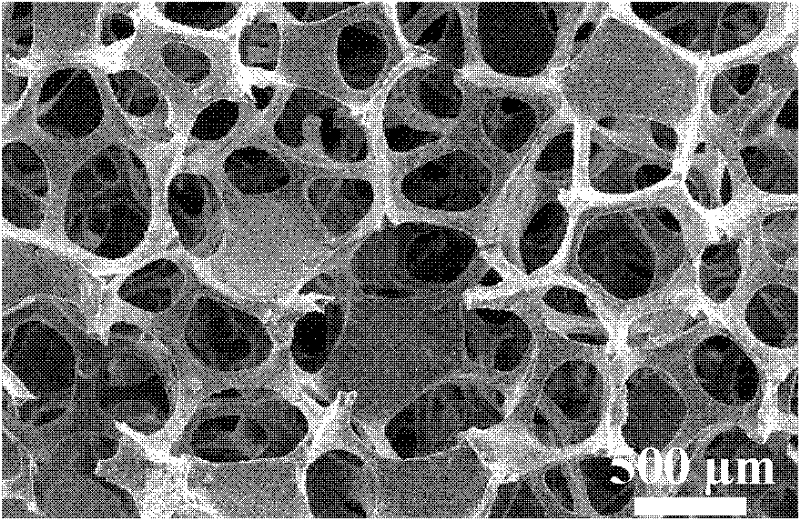

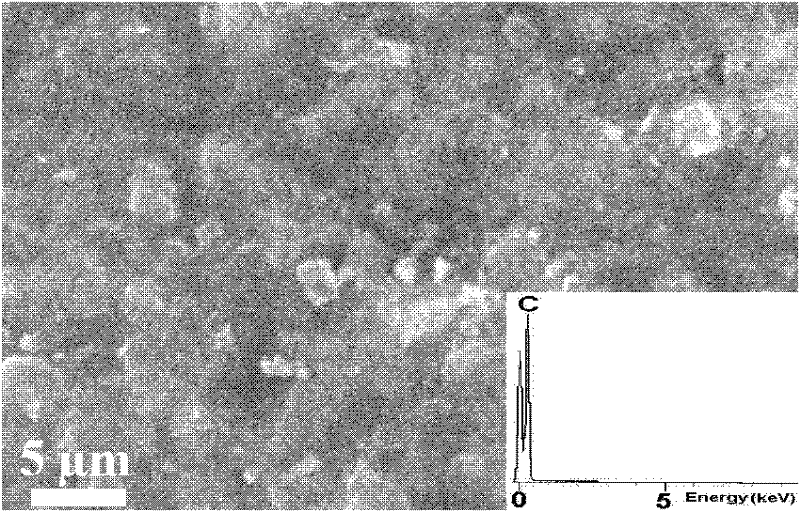

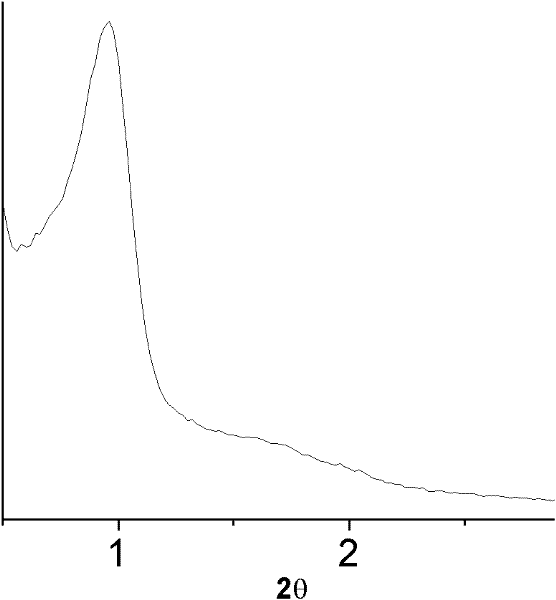

[0021] The resulting foamy ordered mesoporous carbon monolith has a macropore diameter of 500 mic...

Embodiment 2

[0023] Prepare a furfuryl alcohol solution with a mass concentration of 0.1 oxalic acid; prepare a suspension according to the weight ratio of the powdered ordered mesoporous silicon material SBA-15 to the furfuryl alcohol solution of oxalic acid at a weight ratio of 1:6, and stir the suspension for 10 hours; Immerse the fat foam in the obtained suspension for 2 minutes, squeeze out the excess suspension; polymerize and solidify at 80°C for 1 hour to obtain a composite foam, place the above composite foam in a nitrogen atmosphere, and heat at 2°C·min -1 The temperature is raised to 700° C. for carbonization treatment for 1 hour to obtain a composite material of foamy ordered mesoporous silicon material and carbon. The composite material was soaked in 48% hydrofluoric acid for 24 hours, washed until neutral, and dried to obtain a foamy ordered mesoporous carbon monolith.

[0024] The resulting foamy ordered mesoporous carbon monolith has a macropore diameter of 500 microns and ...

Embodiment 3

[0026] Prepare a furfuryl alcohol solution with a mass concentration of 0.05 oxalic acid; prepare a suspension according to the weight ratio of the powdered ordered mesoporous silicon material SBA-15 to the furfuryl alcohol solution of oxalic acid at a weight ratio of 1:8, and stir the suspension for 4 hours; the phenolic resin used as the template Immerse the foam in the obtained suspension for 2 minutes, squeeze out the excess suspension; polymerize and solidify at 80°C for 1 hour to obtain a composite foam, place the above composite foam in a nitrogen atmosphere, -1 The temperature was raised to 900° C. for carbonization treatment for 1 hour to obtain a composite material of foamy ordered mesoporous silicon material and carbon. The composite material was soaked in 48% hydrofluoric acid for 24 hours, washed until neutral, and dried to obtain a foamy ordered mesoporous carbon monolith.

[0027] The resulting foamy ordered mesoporous carbon monolith has a macropore diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com