Yellow disperse dye capable of dyeing in acid and alkaline baths

A disperse dye, yellow technology, applied in the direction of azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of poor dyeing reproducibility, inconvenient dyeing and finishing process, different color depth of fabrics, etc. Sublimation fastness, simplified process, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

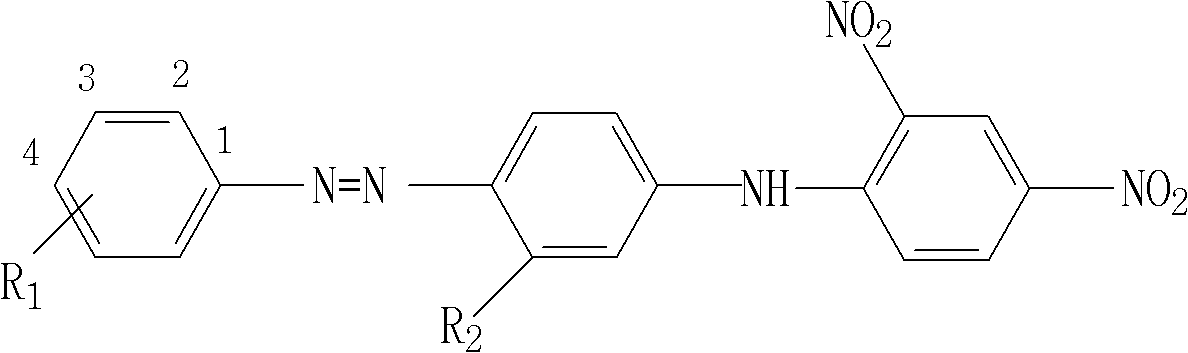

Method used

Image

Examples

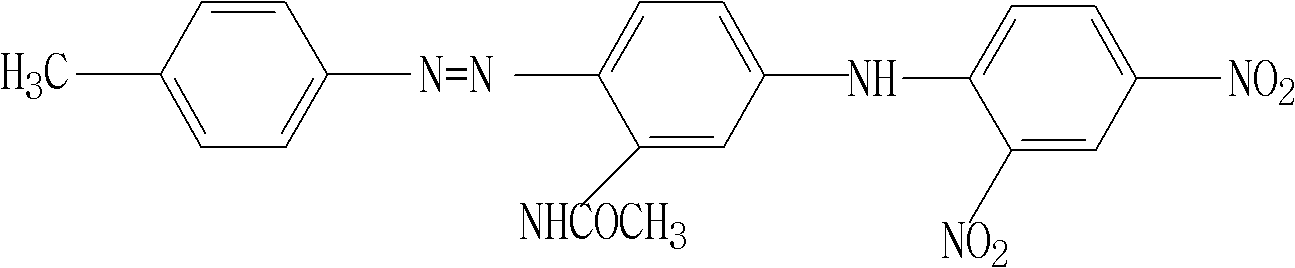

preparation example 1

[0018] Add 100 grams of ice water and 5.46 grams (0.05 gmol) of 98% p-toluidine in a 250 milliliter three-necked flask, then add 15.2 grams of 30% hydrochloric acid, stir until fully dissolved on an ice-water bath, and then stir at 0-10 ° C Add dropwise 14.1 grams (0.051 gmol) of 25% sodium nitrite solution, and react at 0-5°C until p-toluidine disappears, then add about 0.5 gram of sulfamic acid, check with starch potassium iodide test paper until the test paper is colorless after stirring, The diazo solution is to be coupled.

[0019] Add 250 milliliters of water and 7.5 grams (0.049 gmol) of 98% m-aminoacetanilide in a 1000 milliliter beaker, then add 30 grams of 30% hydrochloric acid and stir until completely dissolved, then add the above-mentioned diazonium solution for coupling and reaction Until the coupling component disappears, filter and wash with water until neutral to obtain 30-35 grams of intermediate product filter cake, about 13 grams of dry product.

[0020] A...

preparation example 2-9

[0023] According to the molar ratio of Preparation Example 1, the same synthetic method can obtain the respective corresponding dyes in the general formula of the dyes, and the substituents of the resulting products are shown in the following table:

[0024] Preparation No.

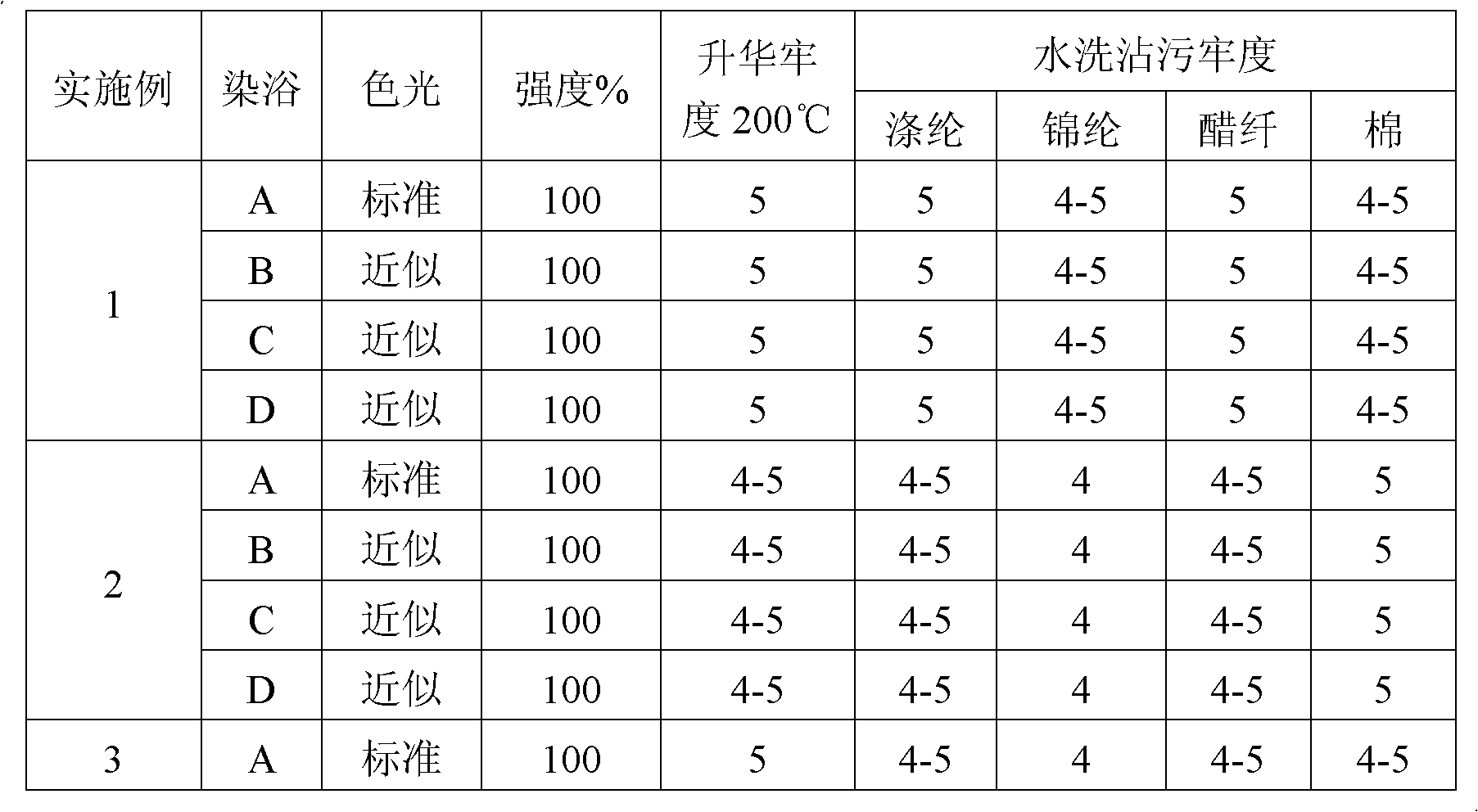

Embodiment 1

[0026] Get 20 grams of the dye of Preparation Example 1, 20 grams of diffusing agent MF, 20 grams of sodium lignin sulfonate and 90 grams of water, and filter when the degree of diffusion reaches 4-5 grades. The dye slurry is quickly dried to obtain yellow disperse dyes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com