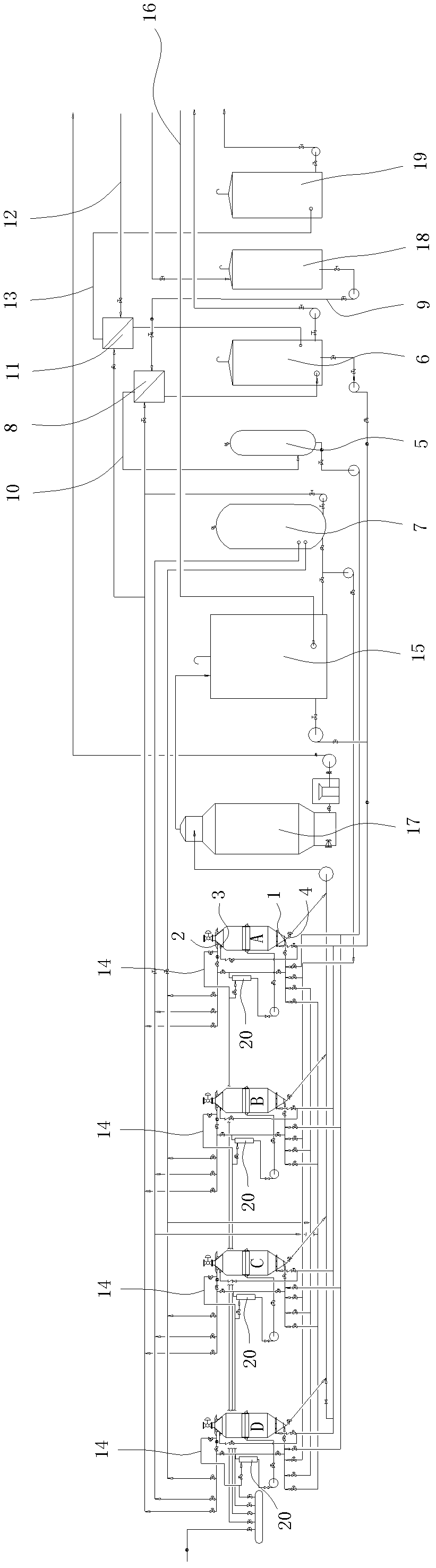

Paper pulp continuous-replacement boiling process

A technology for replacing cooking and pulp, which is applied in the direction of digesters, papermaking, textiles and papermaking, etc. It can solve the problems of large workshop area, high equipment investment, and pressure damage of inner tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

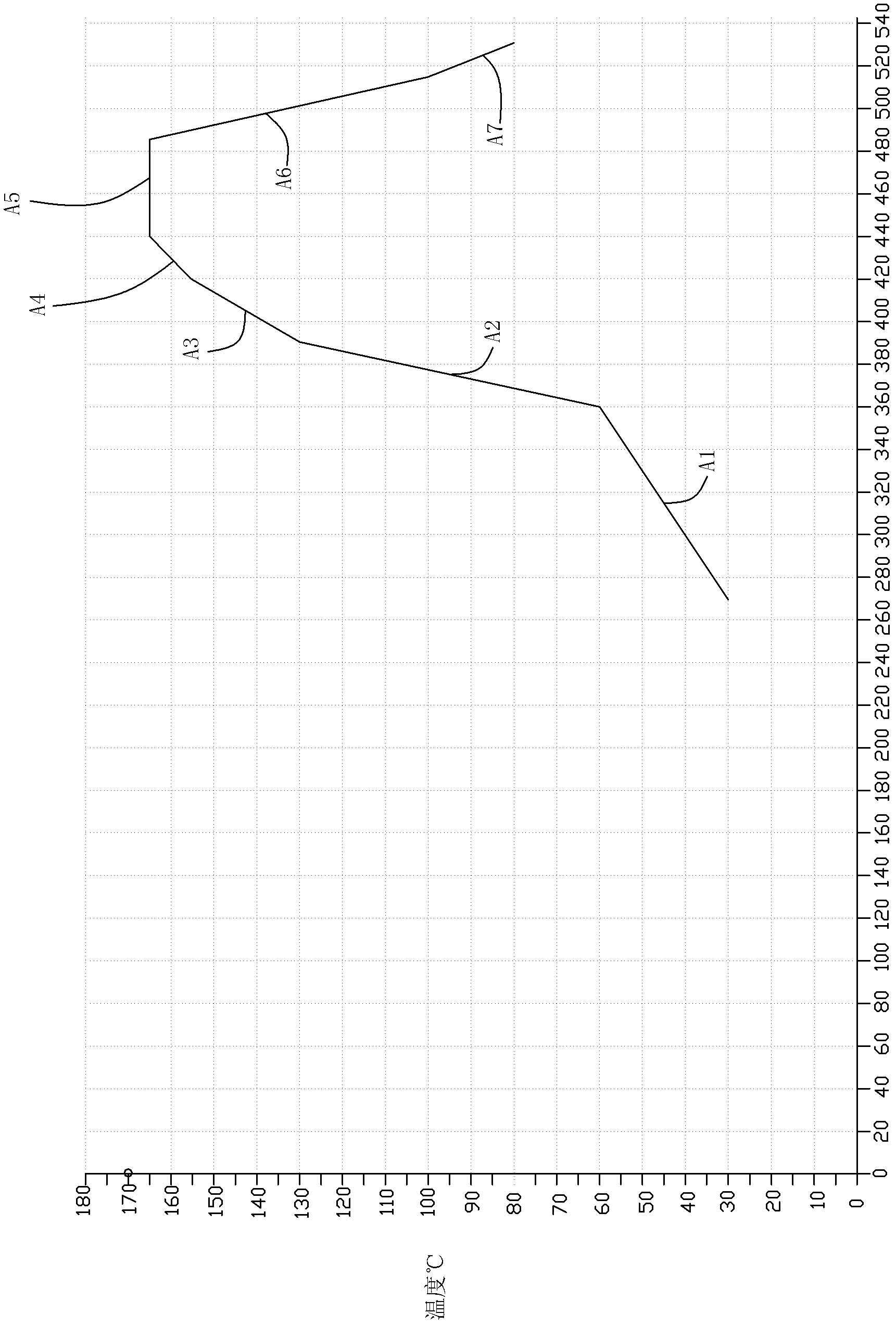

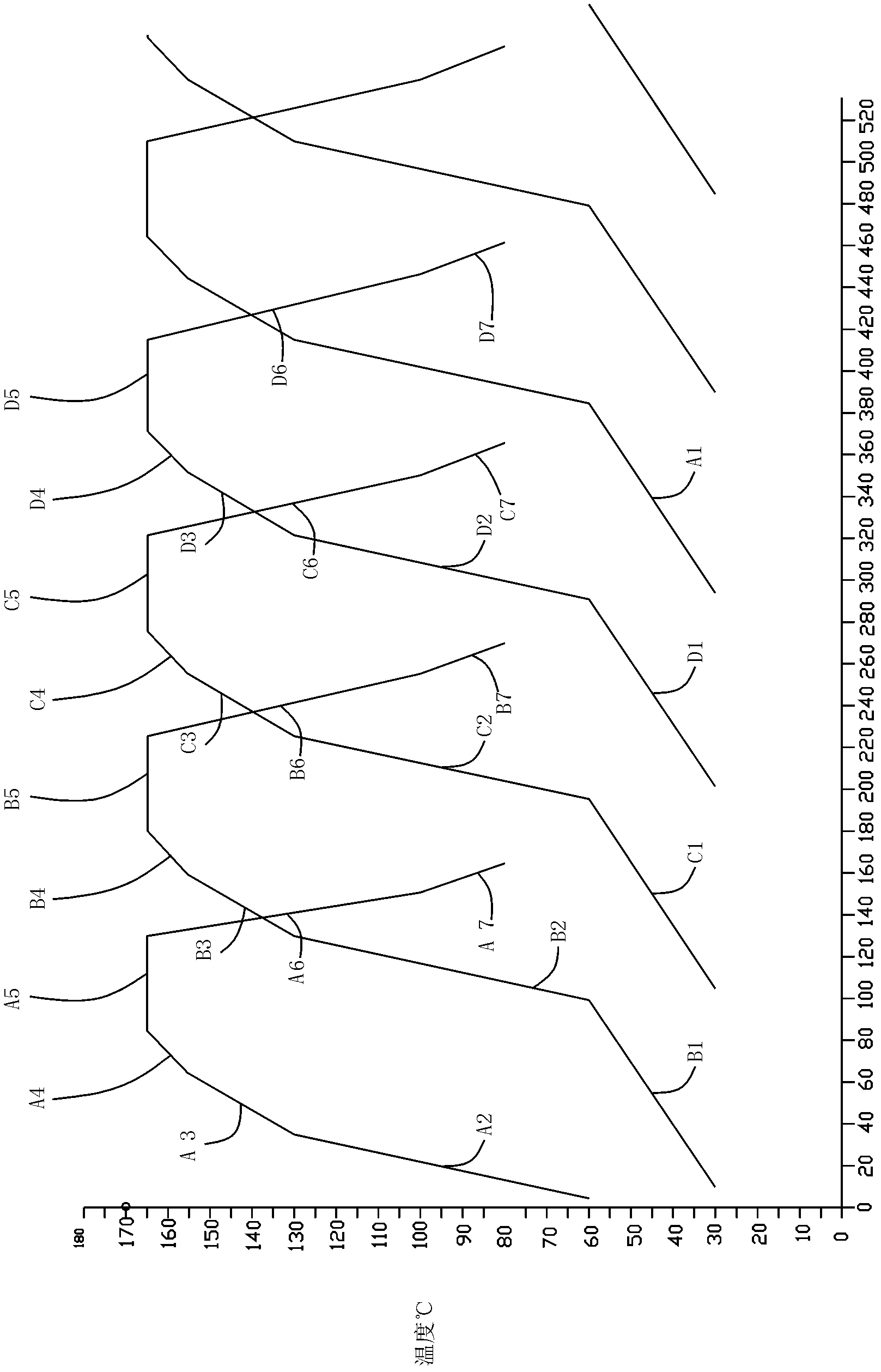

[0138] There are seven process steps in the whole cooking cycle:

[0139] one

two

three

Four

Fives

six

seven

cycle

Pot

primary cooking

intermediate cooking

insulation

Alkali recovery replacement

put the pot

total time

25min

40min

40min

20

60min

40min

15min

240min

[0140] The replacement amount is as follows:

[0141]

[0142]

[0143] When replacing

[0144] V21+V22- remaining space in the pot=V23+V24

[0145] V31+V32=V33+V34

[0146] V61=V63+V64

[0147] V31=V63, the hot black liquor V31 input to the intermediate cooking pot comes from the hot black liquor V63 displaced during alkali recovery and replacement.

[0148] V21=V33, the hot black liquor V21 input to the primary cooking pot comes from the hot black liquor V33 displaced by the intermediate cooking pot.

[0149] 1. Fill pot B (30min)

[0150] The cold black liquor (abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com