Cylindrical composite bridge anticollision device

A composite material and anti-collision device technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of poor anti-collision effect, difficult repair, high cost, etc., and achieve the effect of convenient replacement, convenient installation and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

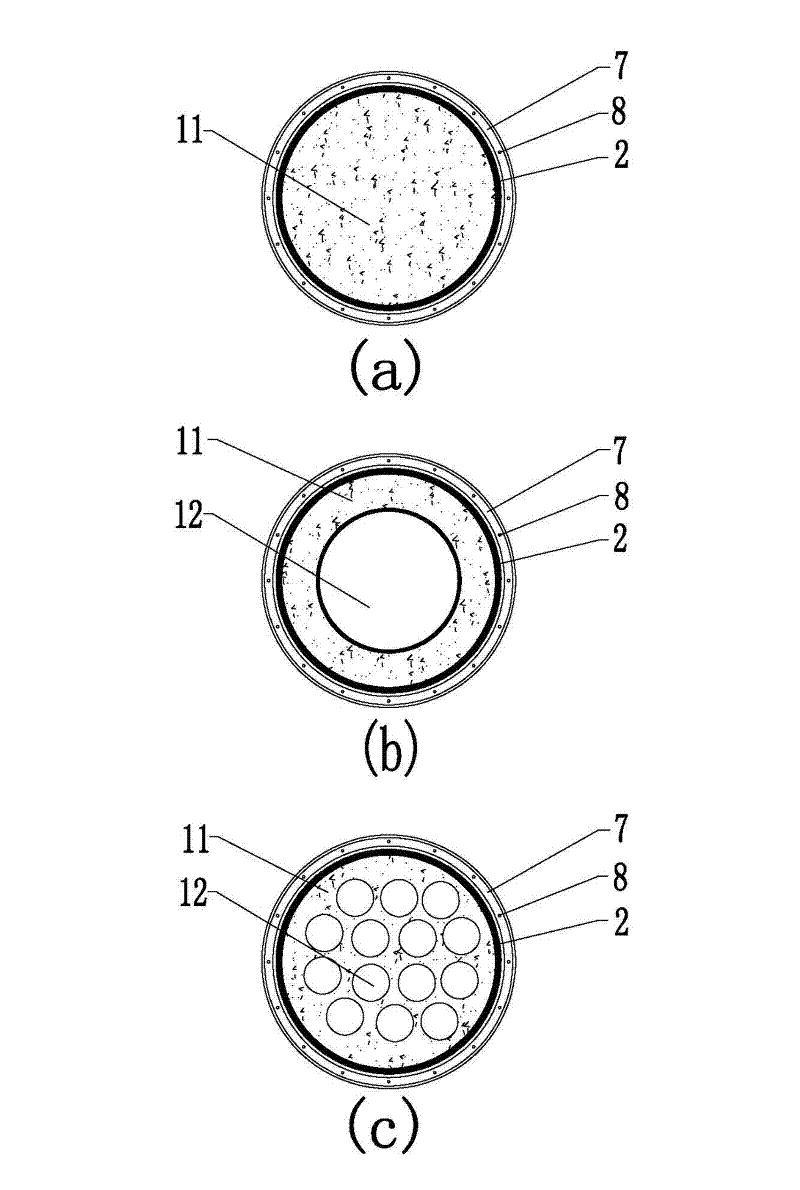

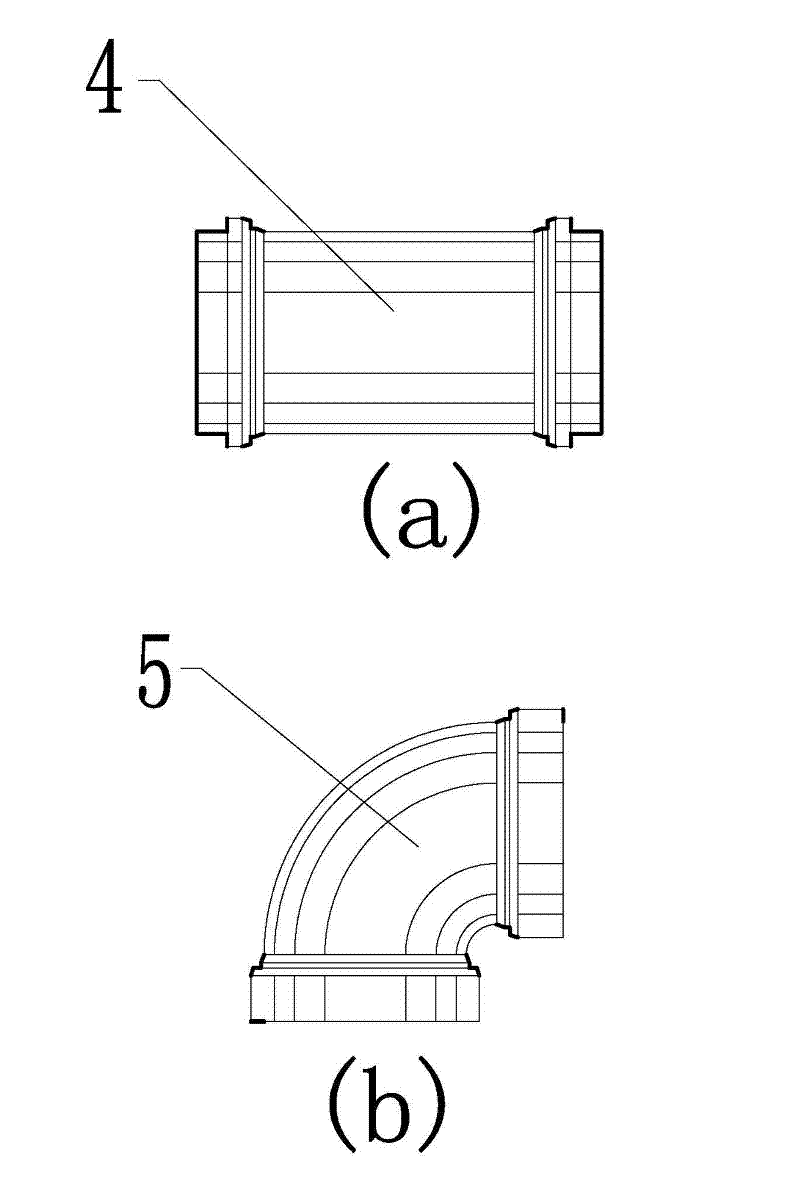

[0033] The tubular composite material bridge anti-collision device of the present invention, as Figure 4 (a) shown. The straight cylindrical anti-collision member 4 is made of basalt fiber cloth and vinyl ester resin through a winding process to form a composite material tube, both ends of which are spherical, and the shell 2 is filled with countless PE hollow spheres with a small diameter as the hollow device 12, the shell The space between the body 2 and the hollow device 12 is tightly filled with recycled rubber particles as a buffer energy-dissipating material 11, and then several straight cylindrical anti-collision members 4 made of composite materials are connected in series through the connecting rod 6 to form a horizontal anti-collision body, which is especially suitable for wharf anti-collision Hitting needs to wait.

Embodiment 2

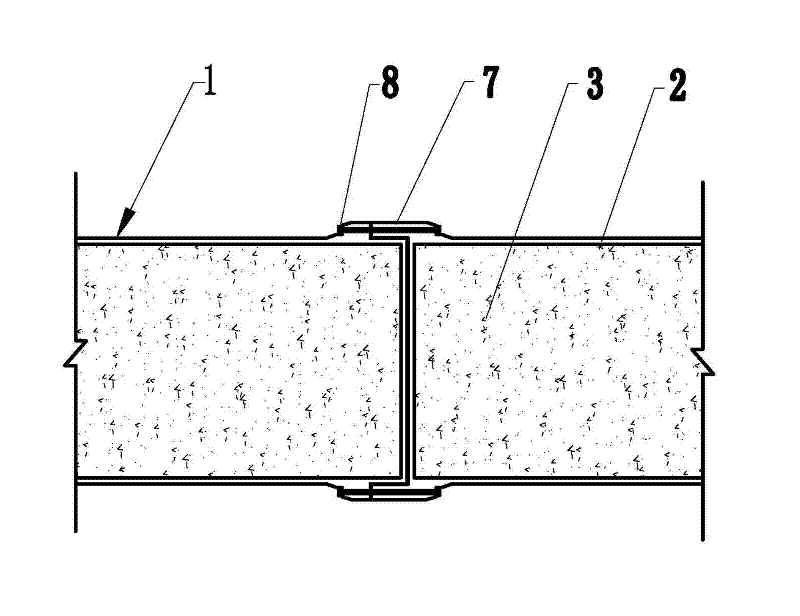

[0035]The tubular composite material bridge anti-collision device of the present invention, as Figure 5 (a) shown. The straight cylindrical anti-collision member 4 is prepared by winding process of glass fiber and unsaturated polyester resin, and the curved cylindrical anti-collision member 5 is prepared by hand lay-up process; both the straight cylindrical anti-collision member 4 and the curved cylindrical anti-collision member 5 are filled with Polystyrene foam mortar is used as a buffer energy-dissipating material 11; the straight cylindrical anti-collision member 4 and the curved cylindrical anti-collision member 5 are connected into a complete rectangular ring device with equal cross-section by using socket flange 7 and bolt 8; Nylon rollers are installed on the contact side of the shaped anti-collision member 4 and the bridge pier as a rolling device 9, and a polytetrafluoroethylene slide plate is installed on the contact side of the socket flange 7 and the bridge pier ...

Embodiment 3

[0037] The tubular composite material bridge anti-collision device of the present invention, as Figure 5 (b) shown. Straight cylindrical anti-collision member 4 is made of glass fiber cloth, emery cloth and unsaturated polyester resin through winding process to form a composite sand-filled pipe, and curved cylindrical anti-collision member 5 is also prepared by winding process; the filling diameter of shell 2 is relatively large 1. Composite winding pipe with both ends closed as hollow device 12, medium coarse sand is tightly filled between hollow device 12 and shell 2 as buffer energy-dissipating material 11, using socket-type flange 7 and bolt 8 to connect the straight tube with variable cross-section The shaped anti-collision member 4 and the curved cylindrical anti-collision member 5 are connected to form a complete rectangular ring structure with variable cross-section.

[0038] The composite material bridge anti-collision device of the present invention is prepared by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com