Method for detecting benzoyl peroxide content of flour simply, conveniently and quickly

A technology of benzoyl peroxide and content, which is applied in the field of fluorescence detection, and achieves the effects of low cost, easy popularization and application, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

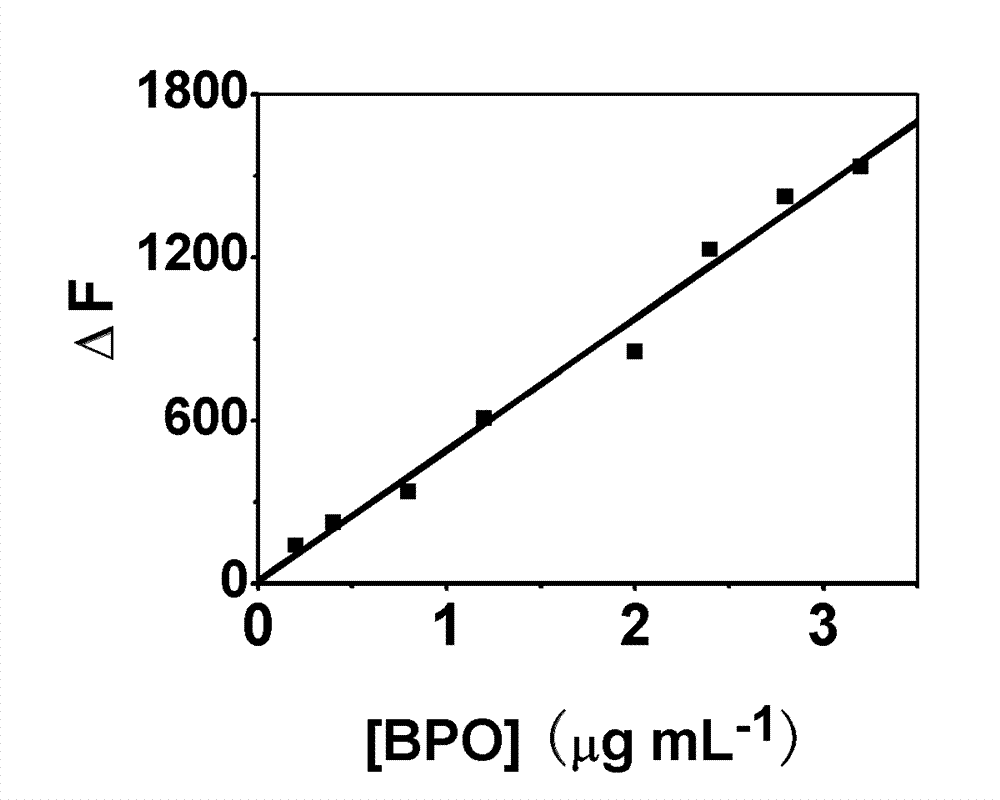

[0022] The mensuration of benzoyl peroxide content in embodiment 1, flour

[0023] 1. Preparation of stock solution:

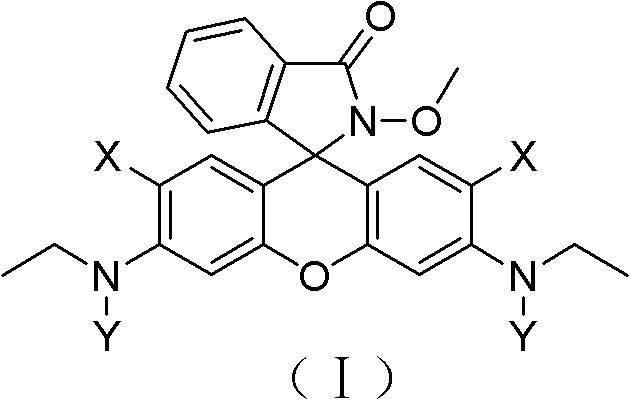

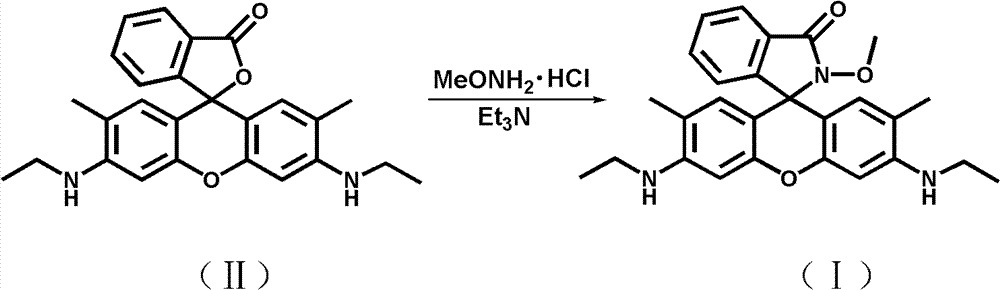

[0024] (1) fluorescent reagent N-methoxyrhodamine 6G lactam (as shown in formula (I), wherein, X is CH 3 , Y is the standard stock solution of H): Accurately weigh 44.35 mg of N-methoxyrhodamine 6G lactam, dissolve it with 100 mL of acetonitrile, and obtain a standard stock solution of N-methoxyrhodamine 6G lactam with a concentration of 1 mM ;

[0025] (2) The standard stock solution of benzoyl peroxide: accurately take by weighing benzoyl peroxide 50mg, dissolve with 100mL ethanol, obtain the standard stock solution of the benzoyl peroxide that concentration is 0.5g / L;

[0026] (3) the standard stock solution of ferrous chloride: accurately take ferrous chloride tetrahydrate 745.2mg, dissolve with 25mL three times of water, obtain the standard stock solution of the ferrous chloride that concentration is 150mM;

[0027] 2. Preparation of sample solution to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com