Lighting dose real-time controlling apparatus in photolithography system

A real-time control and lithography system technology, applied in the semiconductor field, can solve problems such as difficulty in building models, difficulty in long-term guarantee of accuracy, inability to test all exposure conditions, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

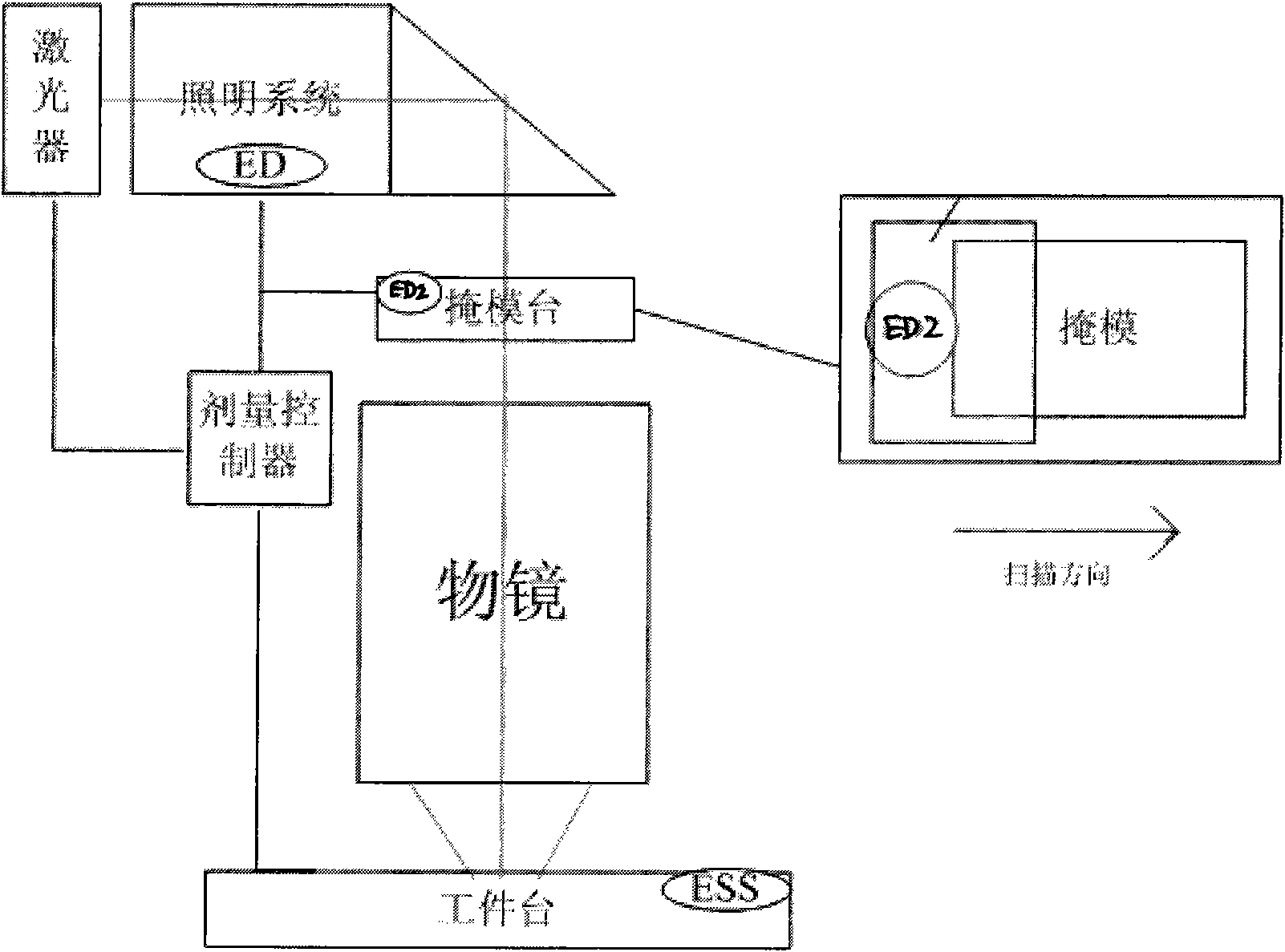

[0020] On the basis of the technical solution described in the background art, an energy sensor ED2 is added to the mask table above the objective lens of the lithography system, which is called the third light energy sensor. The point energy sensor ESS and energy sensor ED mentioned in the background art, They are respectively called the second light energy sensor and the first light energy sensor. Such as figure 2 , the energy sensor ED2 is installed on the center line of the mask stage in the scanning direction, on one side of the mask, adjacent to the mask. During each scanning exposure, the variable slit of synchronous scanning in the illumination system is opened earlier, or closed later, so that the illumination light also scans the energy sensor ED2 before or after scanning the mask; The energy sensor ED2 measures the energy of the pulse, and the pulse energy of the silicon plane can be calculated by multiplying the pulse energy measured by the energy sensor ED2 by t...

Embodiment 2

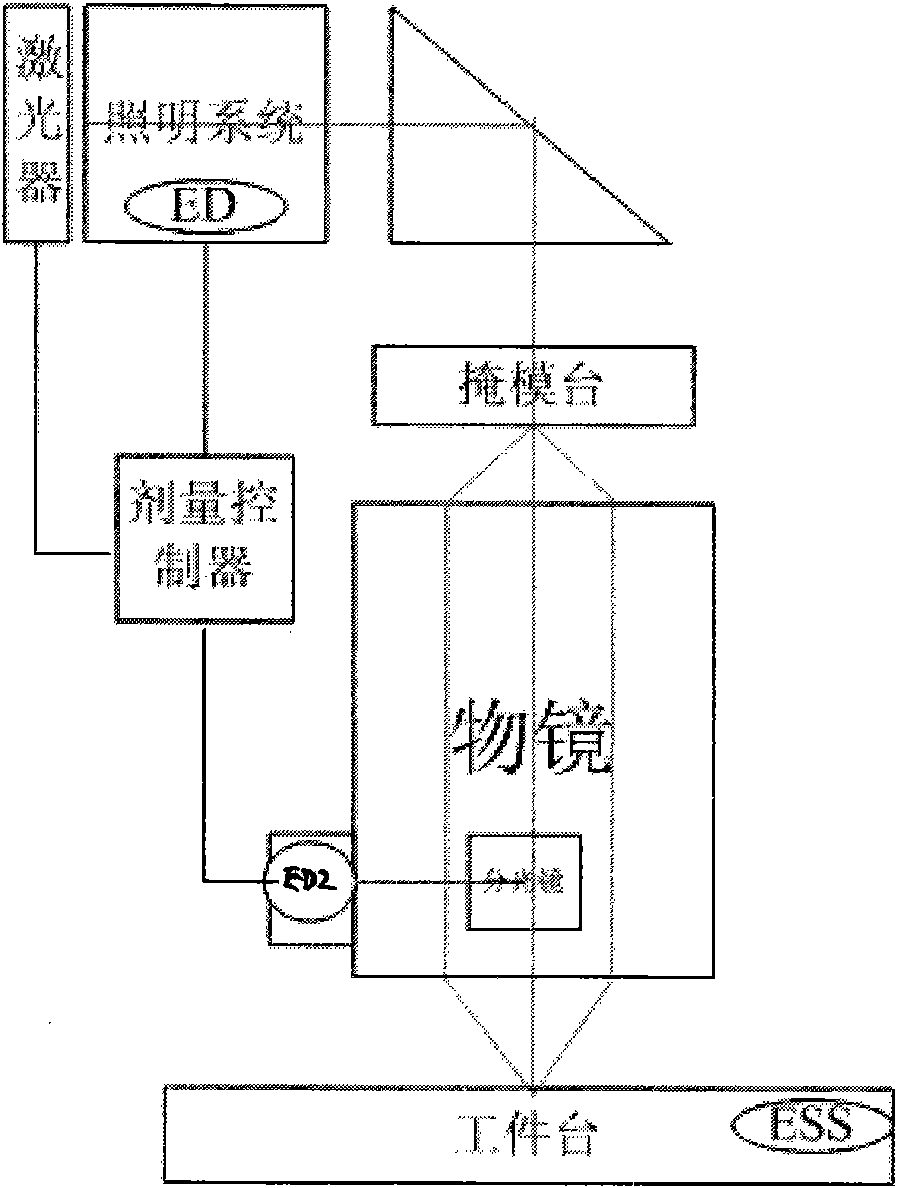

[0029] On the basis of the technical solution described in the background technology, an energy sensor ED2 is added inside the objective lens of the lithography system, which is called the third light energy sensor. The point energy sensor ESS and energy sensor ED mentioned in the background technology are respectively called the first light sensor. Two light energy sensors and a first light energy sensor. Such as image 3 , the energy sensor ED2 is installed on the upper side of the last lens inside the objective lens, and there is a beam splitter inside the objective lens to reflect the diffracted light inside the objective lens to the energy sensor ED2. Because the beam splitter only decomposes a small part of the light in the pupil, it does not affect the imaging and has little effect on the image quality. No matter how the illumination settings are changed, the diffracted light from the mask can always irradiate the beam splitter and be reflected by the beam splitter to ...

Embodiment 3

[0038] On the basis of the technical solution described in the background technology, an energy sensor ED2 is added below the objective lens of the lithography system away from the focal plane, which is called the third light energy sensor. The point energy sensor ESS and energy sensor ED mentioned in the background technology, They are respectively called the second light energy sensor and the first light energy sensor. Such as Figure 4 , the energy sensor ED2 is installed on the side below the last lens inside the objective lens, and there is a beam splitter under the objective lens away from the focal plane, which reflects the diffracted light under the objective lens to the energy sensor ED2. Because the beam splitter only decomposes a small part of the light away from the focal plane, it does not affect the imaging and has little impact on the image quality. No matter how the illumination setting is changed, the diffracted light from the mask can always be irradiated on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com