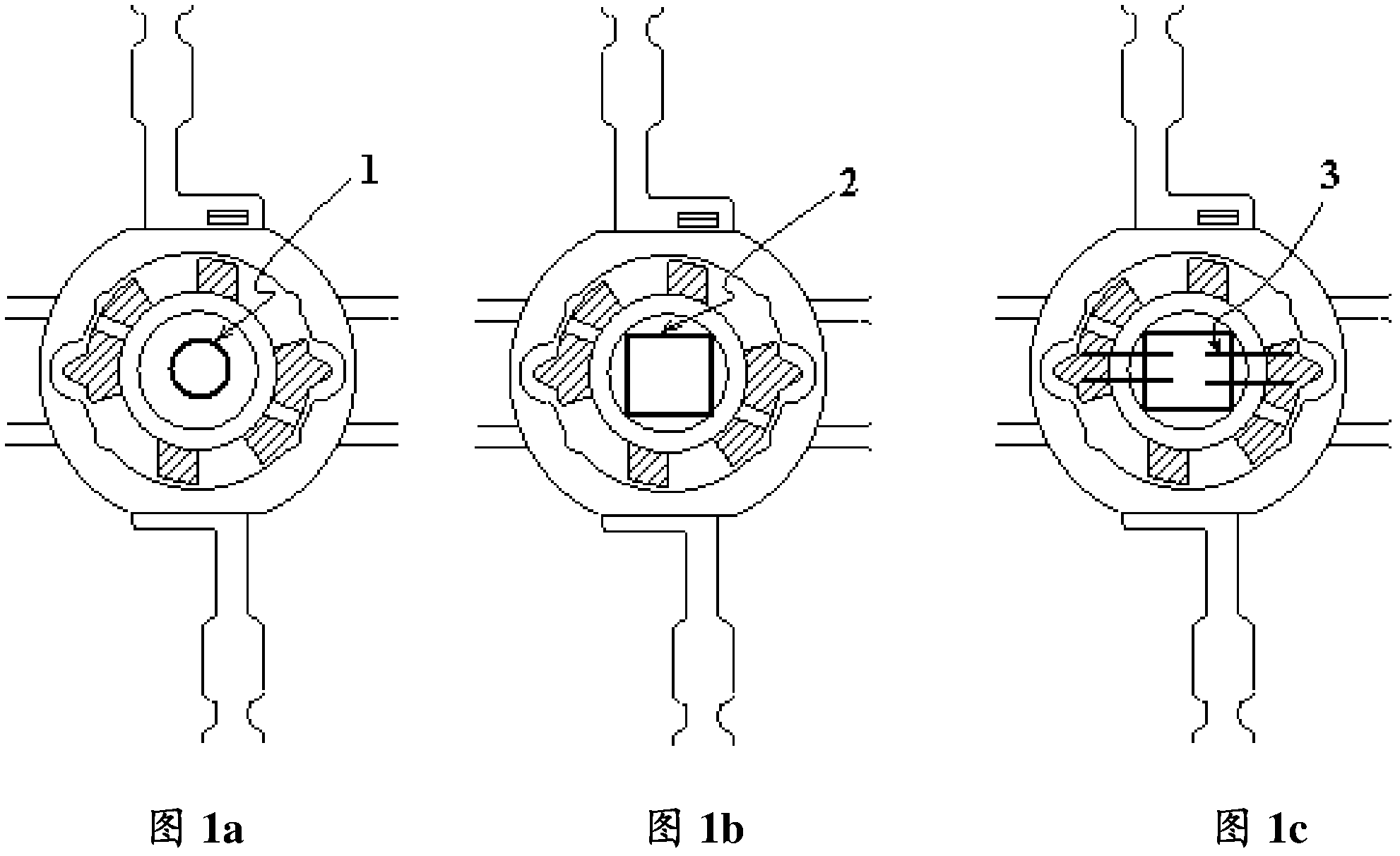

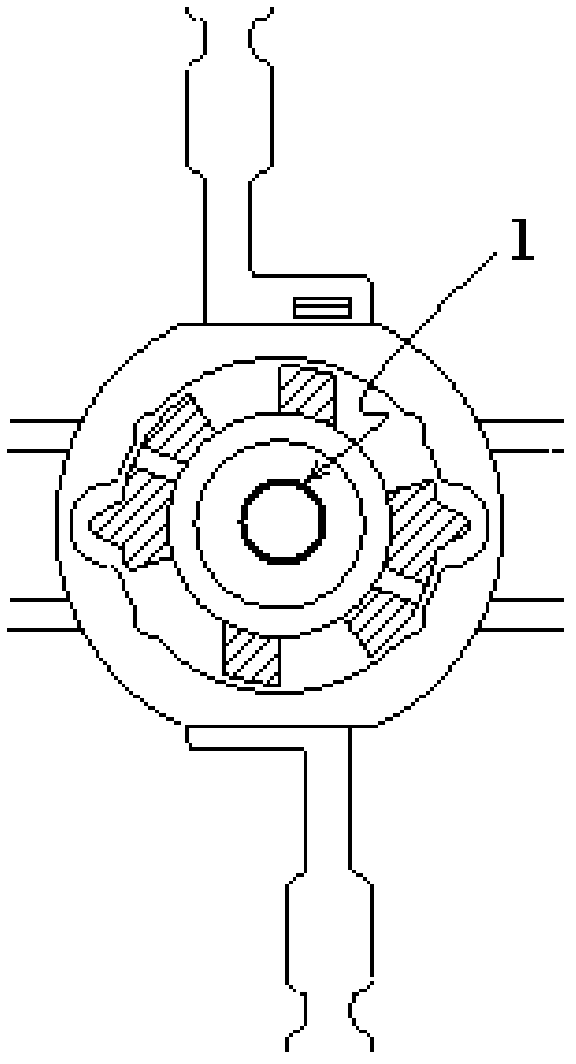

High-power LED (Light-Emitting Diode) encapsulating structure and encapsulating method

A technology of LED packaging and packaging structure, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of large attenuation, poor anti-stress ability, poor thermal conductivity, etc., to achieve the effect of prolonging life and reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment, the present invention is described in detail.

[0018] First of all, analyze the heat conduction problem in the existing technology. The medium between the chip and the bracket of the existing LED is silver glue or white glue, and there is also a eutectic method. The thermal conductivity of the silver glue is generally 2- 3W / mk, the ultra-precious silver glue with special process can only reach 20-30W / mk; the thermal conductivity of white glue does not exceed 3W / mk; the eutectic method, because the required temperature reaches above 350 degrees, is reliable for product quality There is a certain threat, and at the same time, the eutectic produces a lot of internal stress, and there is no buffer between the chip and the frame, and the chip is easily damaged by stress. In this regard, the present invention will use solder for crystal bonding, the thermal conductivity reaches above 50W / mk, the bonding force is much greater than that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com