Protection film substrate special for information technology (IT) product

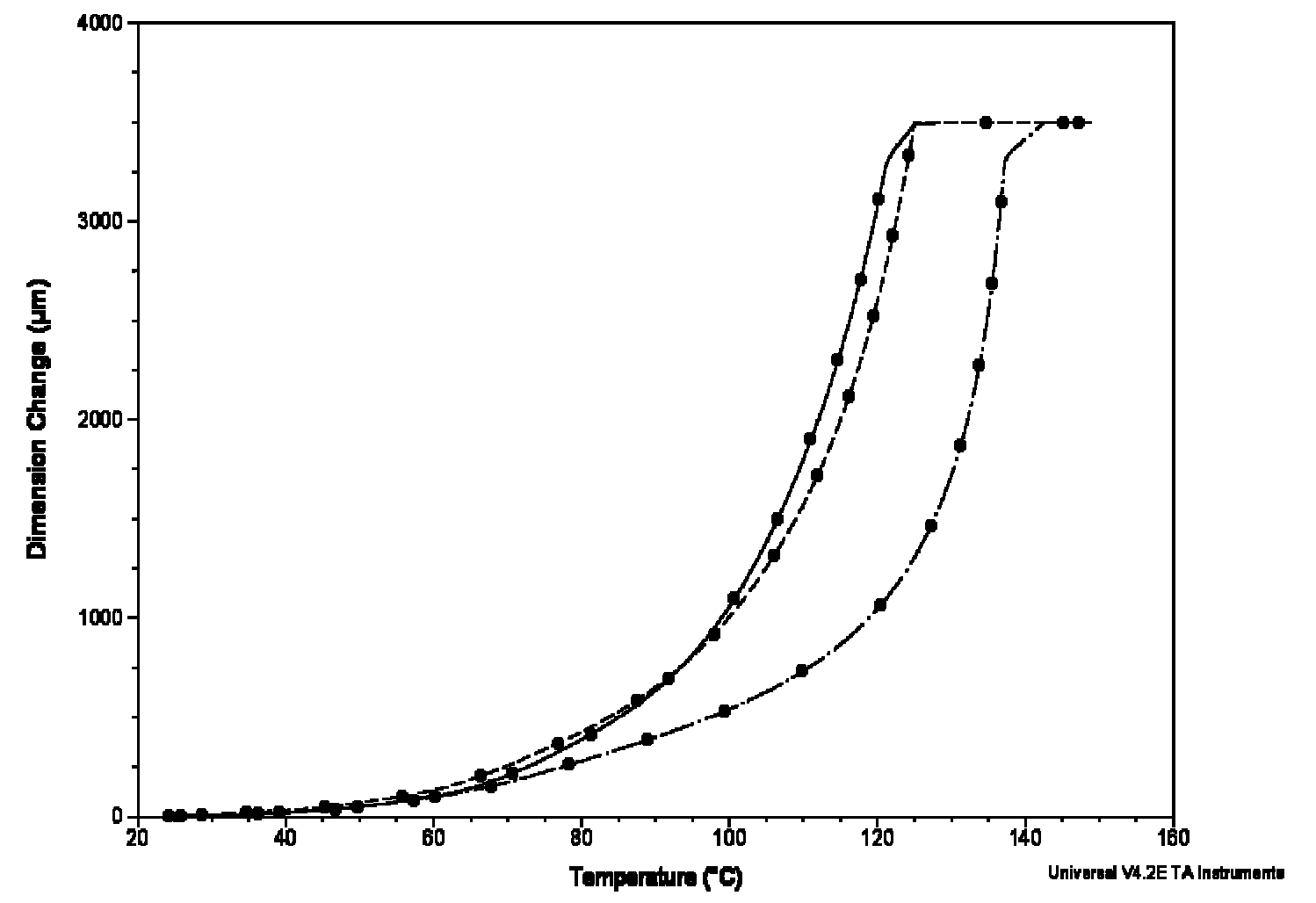

A technology for protective films and substrates, applied in the field of special protective film substrates for IT products, can solve problems such as poor impact resistance, poor heat resistance, and poor film flatness, and achieve good heat resistance and tensile strength. and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Special protective film substrate for IT products, including outer surface layer 1, middle layer 2, inner surface layer 3. The thickness ratios of the three layers are 5%-60% of the outer surface layer and 10%-80% of the middle layer. %, the inner surface layer is 5%-60%.

[0018] In the special protective film substrate for IT products, the main material of the outer surface layer is block copolymer polypropylene or homopolymer polypropylene or a blend of the two, and the main material of the intermediate layer is homopolymer polypropylene or block copolymer polypropylene. Polypropylene or a blend of both; the main material of the inner surface layer is block copolymer polypropylene or homopolymer polypropylene or a blend of both.

[0019] In the special protective film substrate for IT products, the thickness of the protective film substrate is in the range of 20-150 microns, preferably in the range of 30-90 microns.

Embodiment 2

[0020] Example 2: Considering film performance and cost comprehensively, the best ratio of the present invention is:

[0021] Outer surface layer: 100% interlocking copolymer polypropylene, accounting for 20% of the layer thickness,

[0022] Middle layer: 100% homopolymer polypropylene, accounting for 60% of the layer thickness

[0023] Inner surface layer: 100% block copolymer polypropylene, accounting for 20% of the layer thickness.

[0024] According to actual requirements, the raw material ratio and layer thickness ratio of the outer surface layer, middle layer, and inner surface layer can be adjusted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com