A Surfactant-Assisted Hydrothermal Method for the Preparation of Bird's Nest-shaped CO3O4

A technology of surfactant and bird's nest is applied in the field of preparing Co3O4 with bird's nest shape by hydrothermal method, which can solve the problems such as no literature report in the background technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

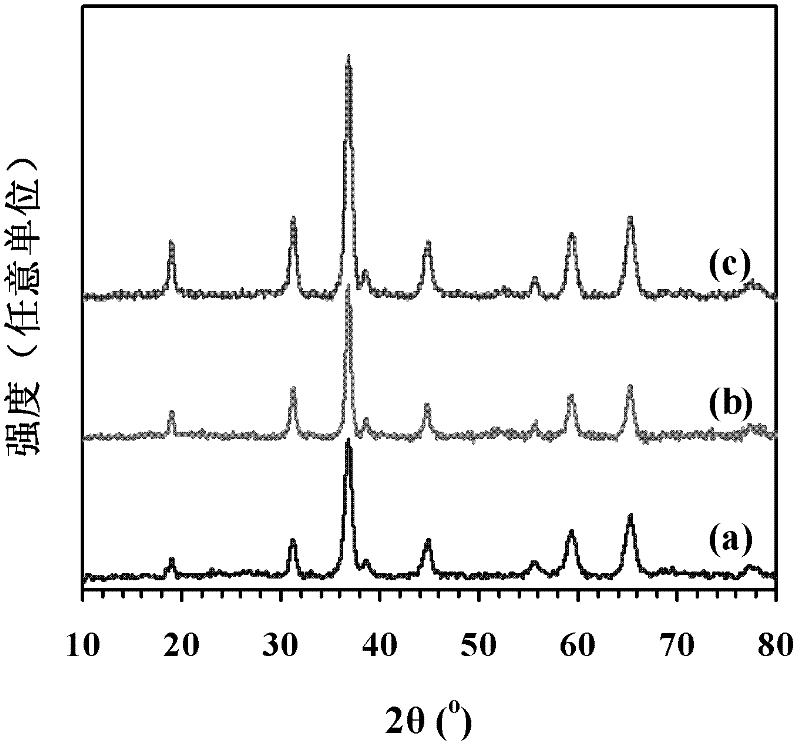

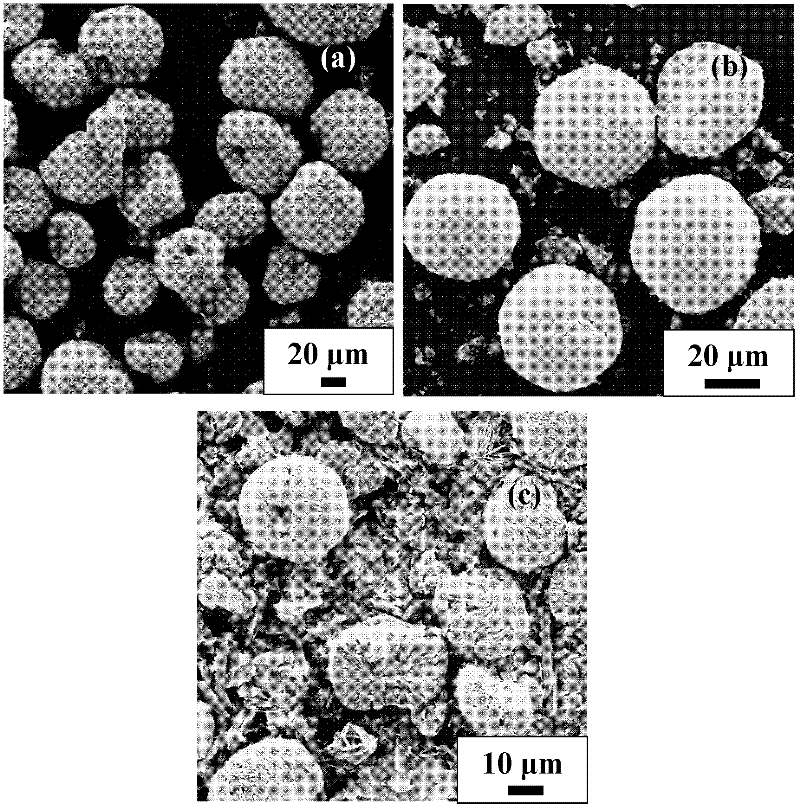

[0012] Embodiment 1: Under the condition of magnetic stirring, ammonia solution is slowly added dropwise to the solution containing 10mmol Co(NO 3 ) 2 In 30mL of transparent aqueous solution, the pH value is controlled between 9 and 10, so that the metal ions can be completely precipitated. Then add 1mL of ethylenediamine, and then transfer the mixture to a 50mL stainless steel reaction kettle lined with polytetrafluoroethylene (80% volume filling), and then put it in a constant temperature box at 140°C for 12h, and then place it at room temperature Cool down, filter the obtained turbid solution with suction, wash, dry (60°C, 12h), and grind evenly to obtain the precursor of the target product, which is then placed in a muffle furnace at a rate of 1°C / min in an air atmosphere Raise the temperature to 300°C and keep at 300°C for 4h to obtain single-phase cubic spinel Co 3 o 4 The powder is in the form of a relatively uniform bird's nest with a scaly surface, with a diameter ...

Embodiment 2

[0013] Embodiment 2: Under the condition of magnetic stirring, ammonia solution is slowly added dropwise to the solution containing 10mmol Co(NO 3 ) 2 In 30mL of transparent aqueous solution, the pH value is controlled between 9 and 10, so that the metal ions can be completely precipitated. Then add 1mL of dodecylamine, then transfer it to a 50mL stainless steel reactor lined with polytetrafluoroethylene (80% volume filling), and then put it in a constant temperature box at 120°C for 24h, and then place it at room temperature After cooling, the obtained turbid solution was suction-filtered, washed, dried (60°C, 12h), and ground uniformly to obtain the target product precursor, which was placed in a muffle furnace and heated to 300°C at a rate of 1°C / min in an air atmosphere. Keep at 300°C for 4h to obtain single-phase cubic spinel Co 3 o 4 The powder is in the shape of a relatively uniform bird's nest with a smooth surface and a diameter of about 42 μm. Its XRD spectrum is ...

Embodiment 3

[0014] Embodiment 3: Under the condition of magnetic stirring, the ammonia solution is slowly added dropwise to the solution containing 10mmol Co(NO 3 ) 2 In 30mL of transparent aqueous solution, the pH value is controlled between 9 and 10, so that the metal ions can be completely precipitated. Then add 1mL of ethylenediamine, then transfer it to a 50mL stainless steel reactor lined with polytetrafluoroethylene (80% volume filling), and then put it in a constant temperature box at 200°C for 12h, and then at room temperature After cooling, the obtained turbid solution was suction-filtered, washed, dried (60°C, 12h), and ground uniformly to obtain the target product precursor, which was placed in a muffle furnace and heated to 300°C at a rate of 1°C / min in an air atmosphere. Keep at 300°C for 4h to obtain single-phase cubic spinel Co 3 o 4 The powder is in the shape of a bird's nest with a scaly surface, and its diameter is about 30 μm. Its XRD spectrum is shown in figure 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com