Treatment method of dye wastewater

A dye wastewater and treatment method technology, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem that activated carbon adsorption method cannot be applied, dye wastewater treatment is not ideal, and dilution methods are not implementation issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

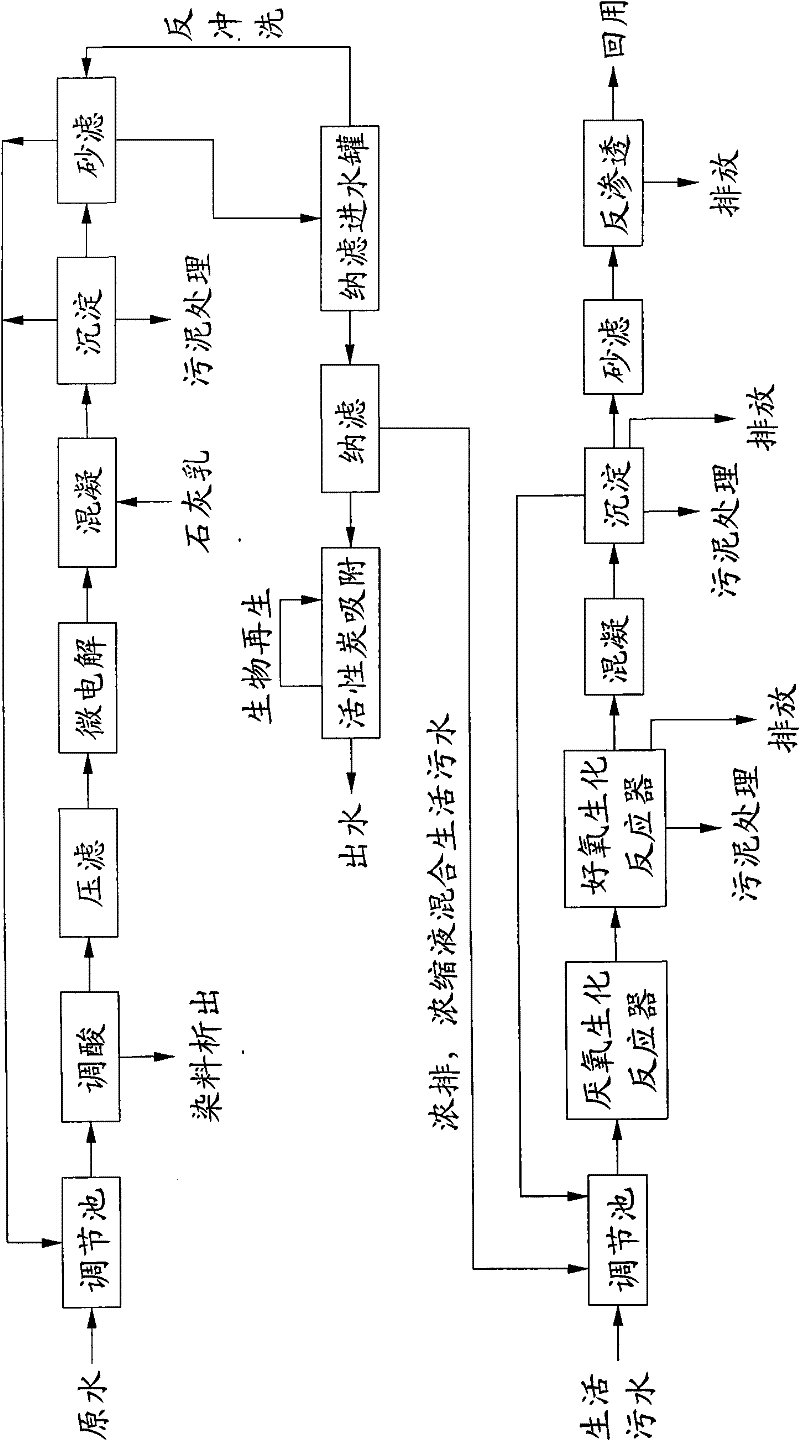

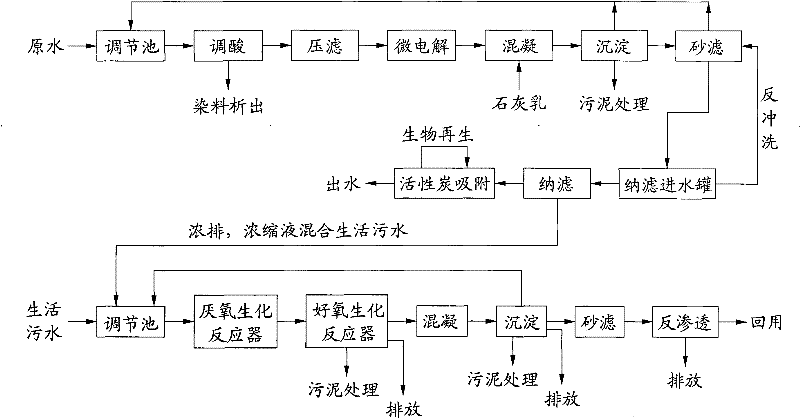

[0040] Such as figure 1 Shown, the present invention is a kind of processing method of dye waste water, and it comprises the following steps:

[0041] (1) Pretreatment: Wastewater is collected through the drainage pipe network and enters the sewage treatment system. The waste water first passes through the grid to remove the large suspended particles contained in the water, and then flows into the homogeneous regulating tank. An underwater mixer is installed in the homogeneous adjustment tank. In order to make the wastewater homogeneous, the residence time is designed to be 24 hours, and then the wastewater is sent to the pH adjustment tank by the lift pump for acid adjustment treatment.

[0042] The separation efficiency of traditional mechanical grids and screens is very low. In this design, mechanical rotating grids are used to remove solid substances to ensure the smooth operation of subsequent processes.

[0043] (2) Acid adjustment and pressure filtration treatment: ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com