A preparation method of a submicron-sized two-dimensional dielectric columnar photonic crystal

A photonic crystal and sub-micron technology, applied in the direction of microlithography exposure equipment, crystal growth, chemical instruments and methods, etc., can solve the problems of difficulty in obtaining columnar structures, differences in development speed, and thorough development, etc., and achieve good application prospects. Simple operation and low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

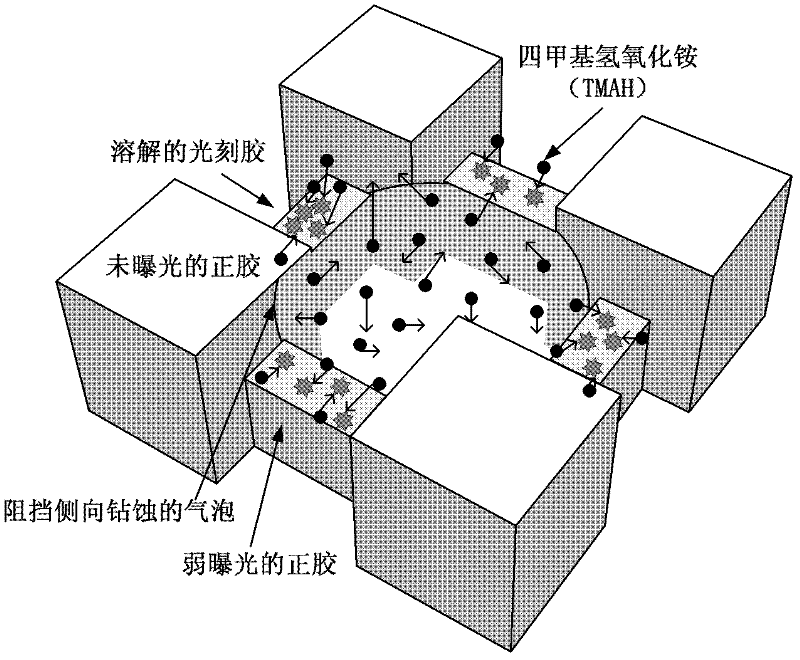

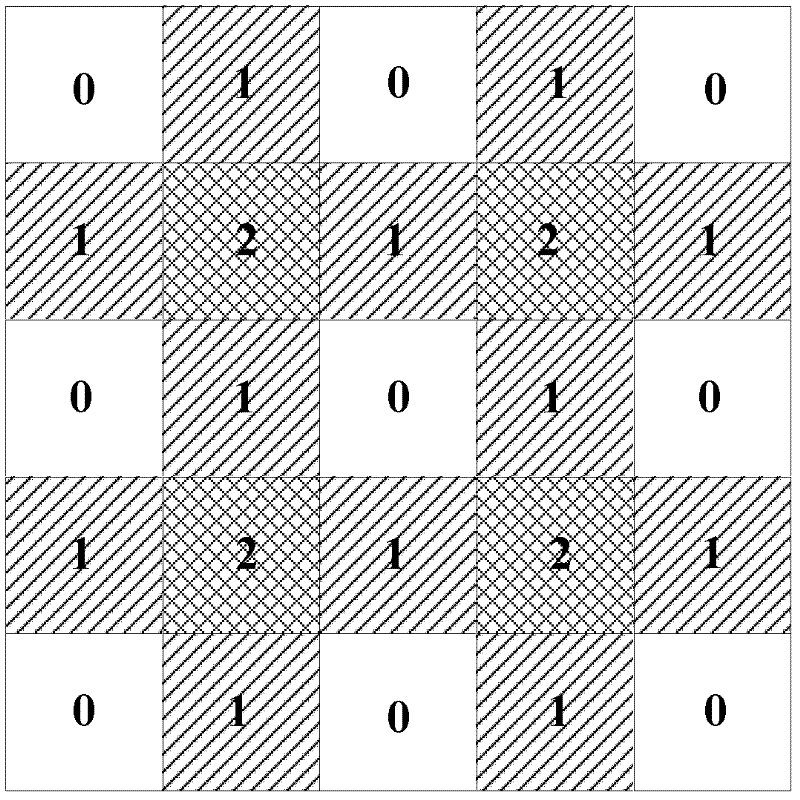

Method used

Image

Examples

Embodiment 1

[0039] (1) Cleaning the substrate: The InP substrate was ultrasonically cleaned three times with carbon tetrachloride, acetone, and ethanol in sequence, then rinsed with deionized water and dried with nitrogen; and finally baked in an oven.

[0040] (2) PECVD deposition of Si 3 N 4 : Put the baked InP substrate into PD-I plasma deposition platform to deposit Si 3 N 4 , The deposition thickness is 100nm.

[0041] (3) Spin-coated photoresist: The photoresist used consists of S6809 brand photoresist (SHIPLEY company in the United States) and E2 brand thinner (SHIPLEY company in the United States) (the main components are ethyl lactate Ethyl lactate) in volume ratio It is prepared by 1:2, and spin-coated for 30 seconds at a rotation speed of 6000 rad / min to obtain a photoresist thickness of 120 nm.

[0042] (4) Soft bake: The sample that has been spin-coated with photoresist is baked on a hot plate at 100°C.

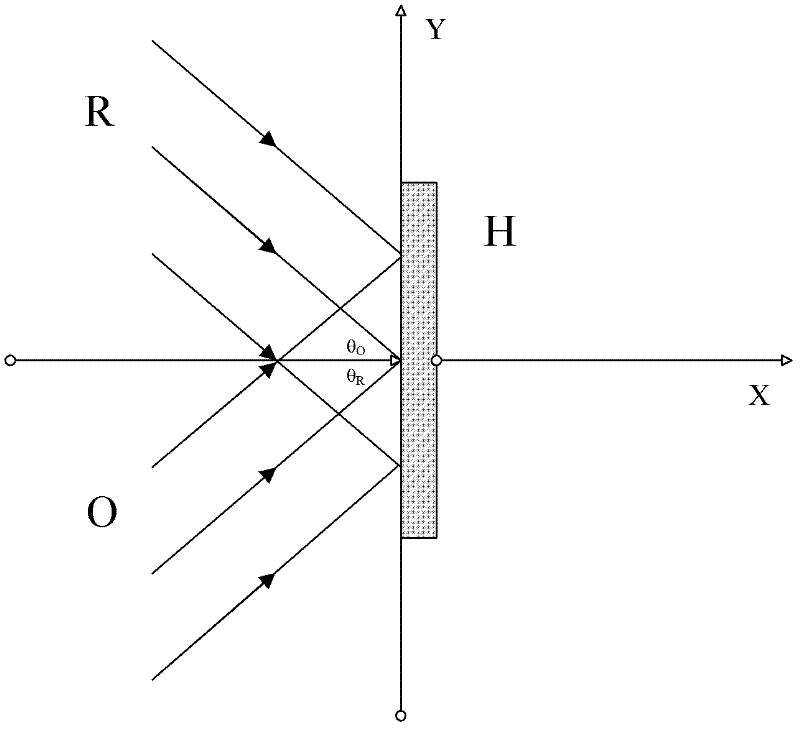

[0043] (5) Vertical cross exposure: Rotate the rotating bracket so that the ang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com