Fermented whey preparation and its production method

A technology of fermented milk and lactic acid fermentation, applied in the direction of whey, dairy products, milk preparations, etc., which can solve the problem of unconceived solid content concentration of whey aqueous solution, unconceived lactic acid bacteria and/or yeast fermentation, and unrepresented thermal stability and other issues, to achieve the effect of fresh and refreshing flavor, effective production, thermal stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

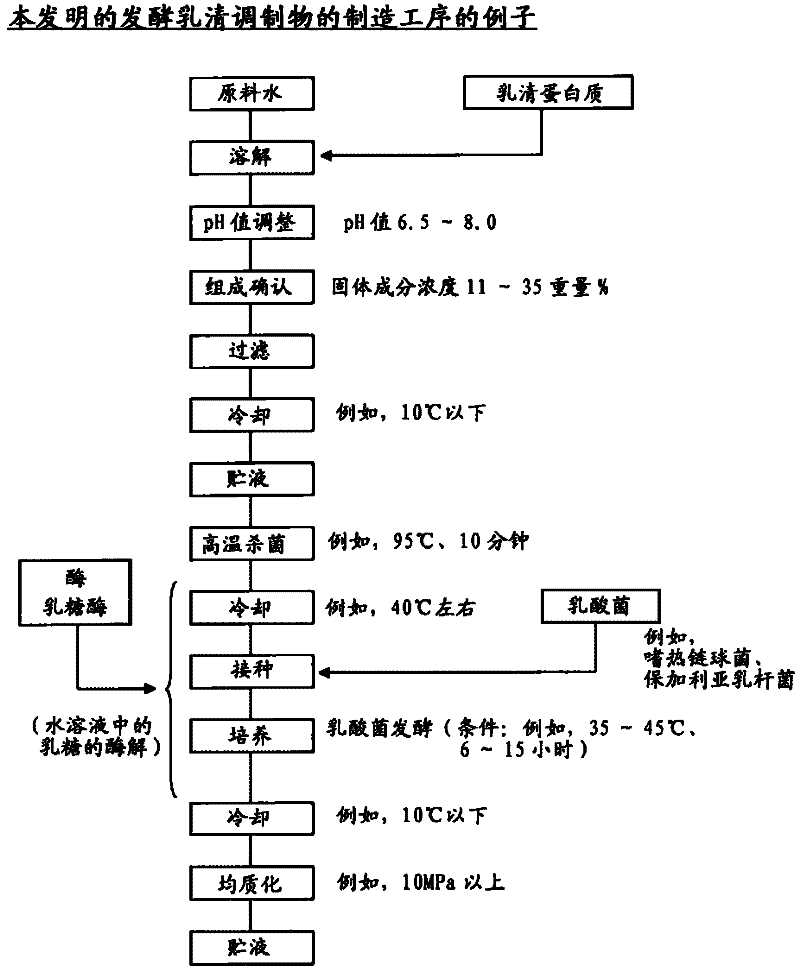

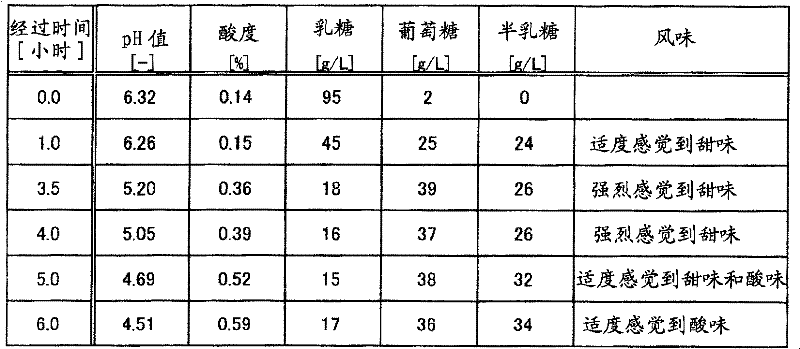

[0090] Example 1 (the present invention): Preparation of fermented whey preparation (when using lactic acid bacteria and lactase)

[0091] As whey protein, 140 g of sweet whey powder (manufactured by Meiji Dairy Co., Ltd.) was prepared, dissolved in deionized water, and a whey protein aqueous solution (whey aqueous solution) with a solid content concentration of 14% by weight was prepared, and then oxidized with hydrogen Sodium acts as a pH adjuster, adjusting the pH to about 7.0. Next, the whey protein aqueous solution was heat-sterilized at 95° C. for 10 minutes by scalding in boiling water. After sterilization, the aqueous solution was observed to contain aggregate particles smaller than 100 μm (average particle diameter: 3 μm). The resulting aqueous solution was cooled to 43°C.

[0092] Next, a frozen concentrate of lactic acid bacteria starter (isolated from "Bulgaria Yoichi Glut" (product name) manufactured by Meiji Dairy Co., Ltd.) was added to the whey protein aque...

example 2

[0102] Example 2 (comparative example): Preparation of fermented whey preparation (when lactase is not used)

[0103] Tests and evaluations were performed in the same manner as in Example 1, except that lactase (lactose decomposing enzyme) was not added during lactic acid fermentation.

[0104] The results are shown in Table 2.

[0105] Table 2

[0106]

example 3

[0107] Example 3 (comparative example): Preparation of fermented whey preparation (when lactic acid bacteria are not used)

[0108] Tests and evaluations were performed in the same manner as in Example 1, except that predetermined lactic acid bacteria were not added during lactic acid fermentation (lactase was added).

[0109] The results are shown in Table 3.

[0110] table 3

[0111]

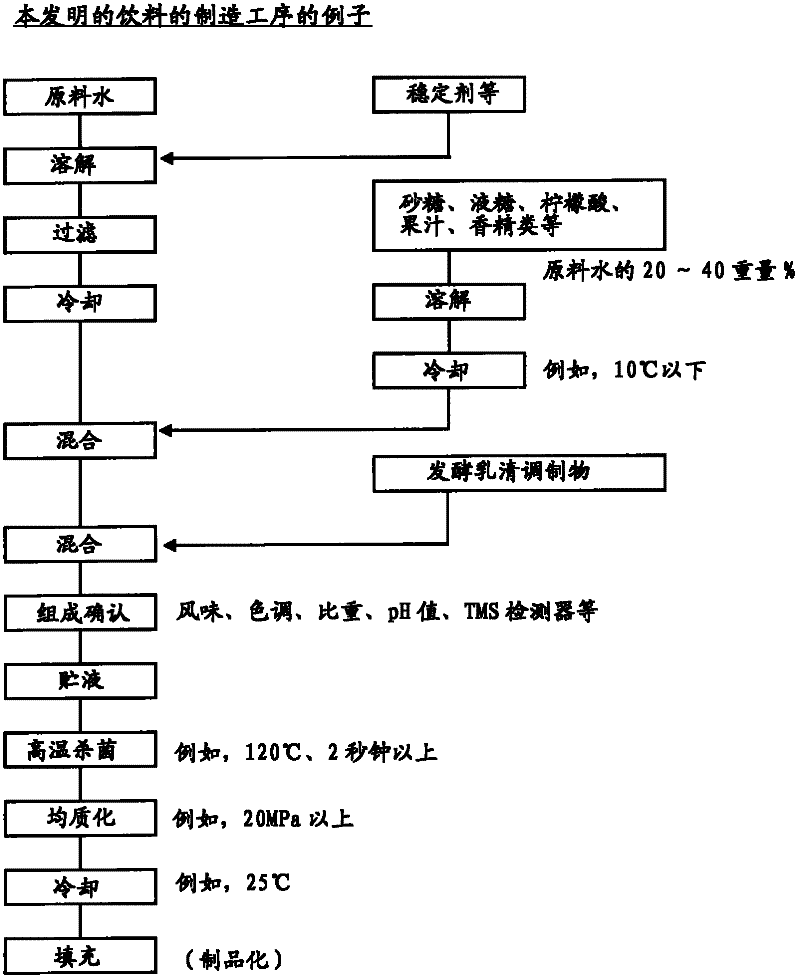

[0112] Beverage product example

[0113] Using the fermented whey preparation obtained in Example 1 above (hereinafter referred to as whey fermented milk), the following formulations were used to manufacture according to the method of the present invention, thereby producing the following beverage products of the present invention.

[0114] In addition, the following ratio or % means the ratio or % of a weight basis unless otherwise indicated.

[0115] Coordination example 1 (drink 1):

[0116] Table 4

[0117] Matching rate (%)

Amount added (g)

whey ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com