Corrosion-resistant steel for crude oil tankers

A corrosion-resistant steel technology, applied in the field of corrosion-resistant steel for crude oil tankers, can solve the problems of electrolytic protection not working, corrosion, etc., and achieve the effect of excellent general corrosion resistance and local corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

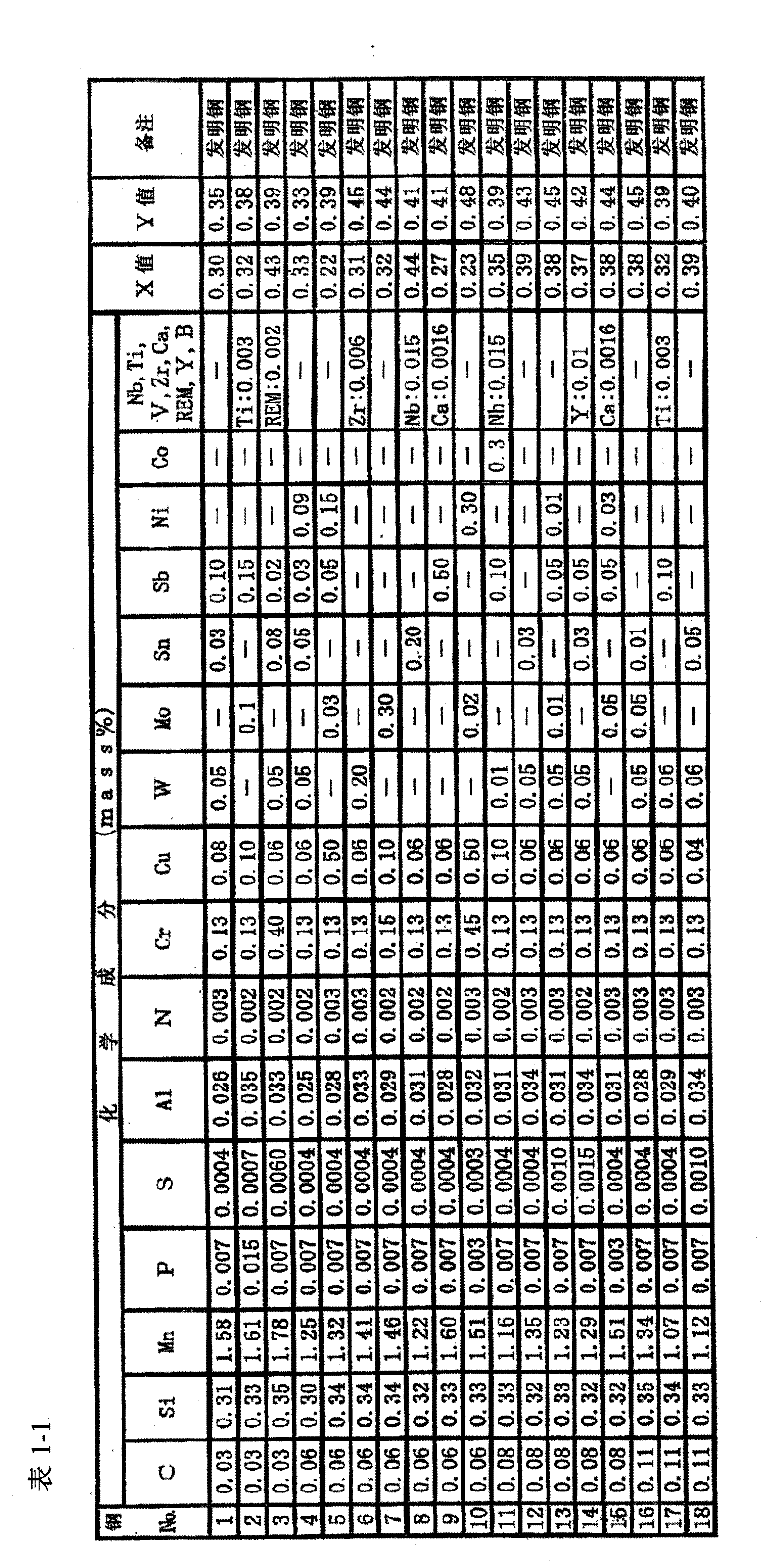

[0106] Various steels having the compositions of Nos. 1 to 36 shown in Table 1 were melted in a vacuum melting furnace or a converter to produce steel ingots or steel slabs, and the obtained steel ingots or steel slabs were reheated to 1200° C., and then Hot rolling at a finishing temperature of 800° C. was performed to obtain a thick steel plate with a plate thickness of 16 mm. The steel plates of Nos. 1 to 36 obtained above were subjected to the following three kinds of corrosion resistance tests.

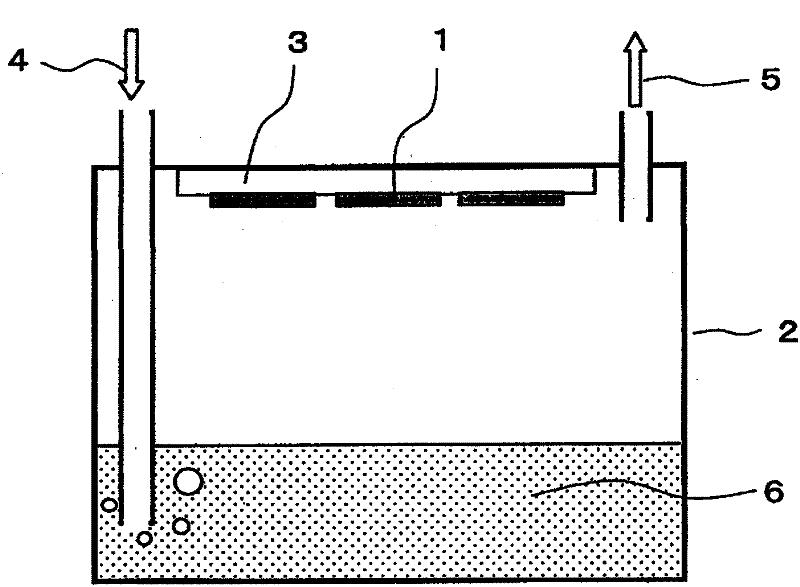

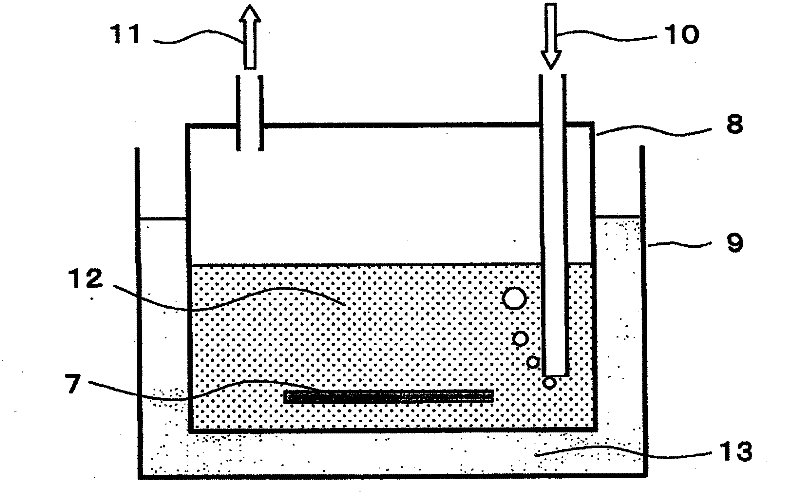

[0107] (1) Comprehensive corrosion test simulating the environment on the upper deck of an oil tanker

[0108] In order to evaluate the corrosion resistance to the general corrosion of the back of the upper deck of the oil tanker, cut rectangular pieces with a width of 25 mm x a length of 48 mm x a thickness of 4 mm from the thick steel plates of No. 1 to 36 above, and perform shot blasting (shot blasting) on the surface. ), so as to make a corrosion test piece in the bare sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com