Polysilicon cleaning method and cleaning device, and polysilicon manufacturing method

A cleaning device and polysilicon technology are applied in the cleaning and cleaning device of polysilicon, and the manufacturing field of polysilicon, which can solve the problems of lowering the quality of monocrystalline silicon and achieve high-quality effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

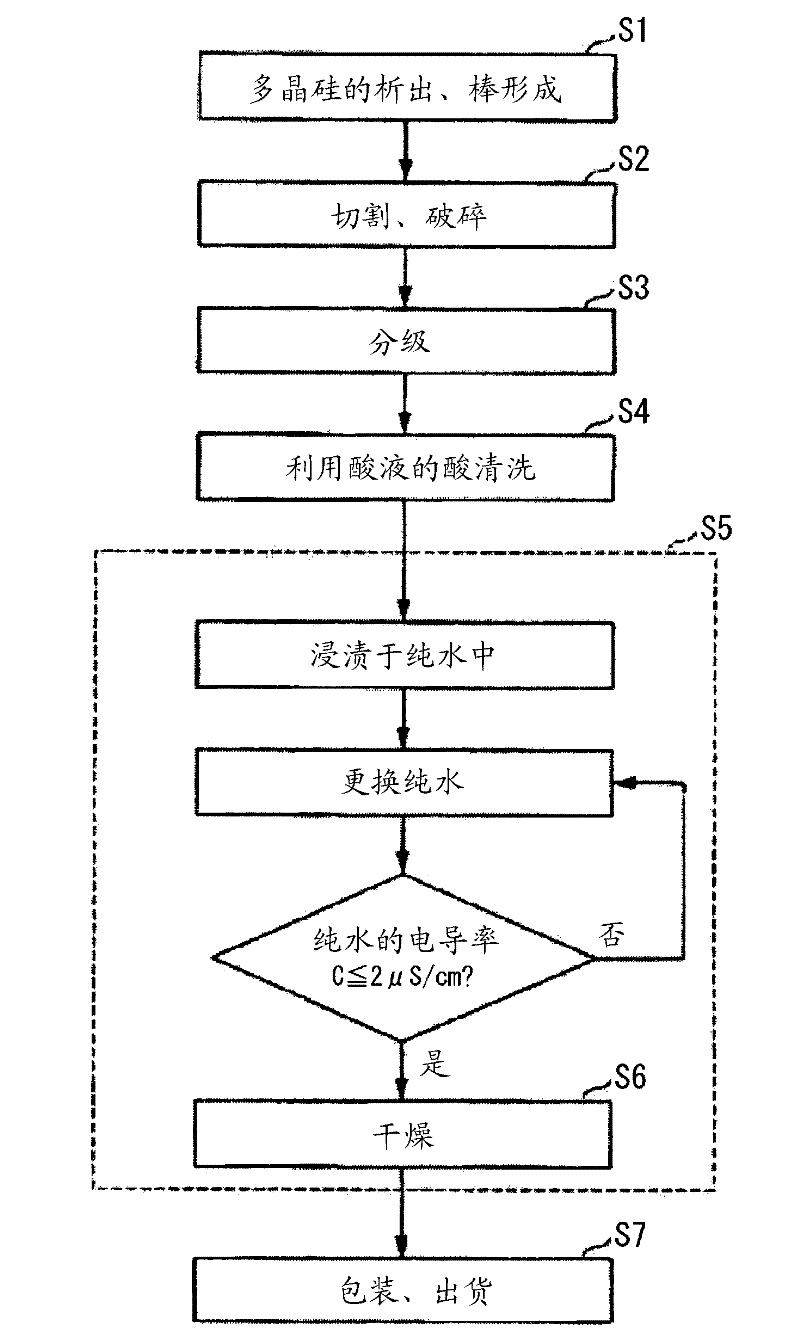

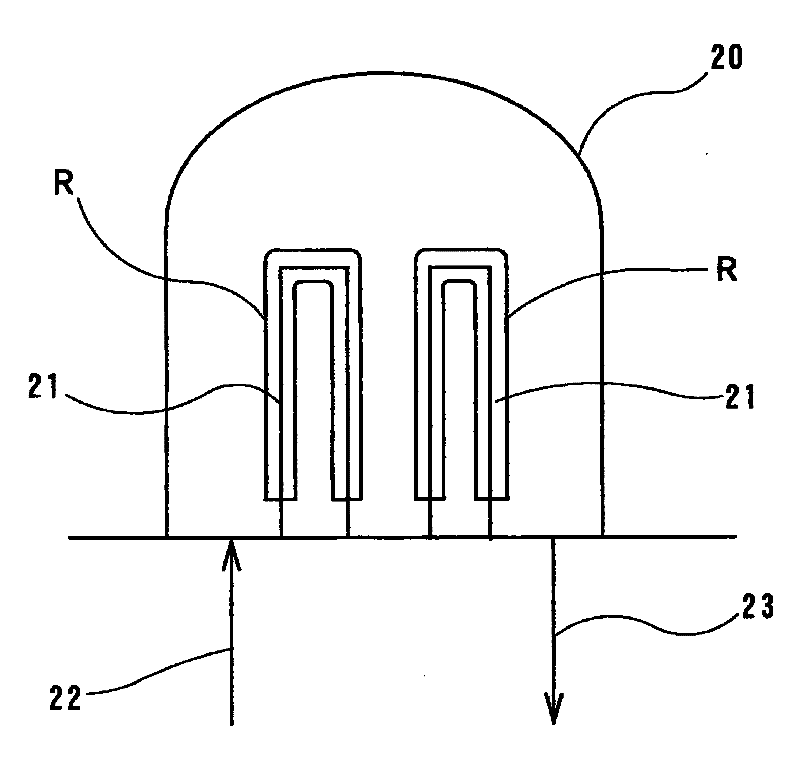

Method used

Image

Examples

Embodiment

[0100] According to the above-mentioned cleaning method, polysilicon was cleaned several times under different conditions.

[0101] For any one cleaning, a large amount of one type of polysilicon is dipped in one washing tank. In Table 1, "thick block (large)" refers to a material with a large block of polysilicon, specifically, a material with a diameter of about 50 mm to 100 mm, and "thick block (small)" refers to a material with a small block of polysilicon , specifically, refers to a substance with a diameter of about 5 mm to 50 mm. Also, a plurality of baskets accommodating polycrystalline silicon lumps in an amount of 5 kg were prepared, and these were immersed in one water washing tank with a required weight according to each condition. The analysis of impurities was performed using ICP-MS (Inductively Coupled Plasma Mass Spectrometry). However, since the amount of impurities actually measured was extremely small, the lower limit of quantification is shown in Table 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com