Infant smear-type processed cheese, and preparation method thereof

A technology for remanufacturing cheese and infants, applied in dairy products, cheese substitutes, applications, etc., can solve problems such as heavy burden on the kidneys, achieve improved digestion and absorption, and have a significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

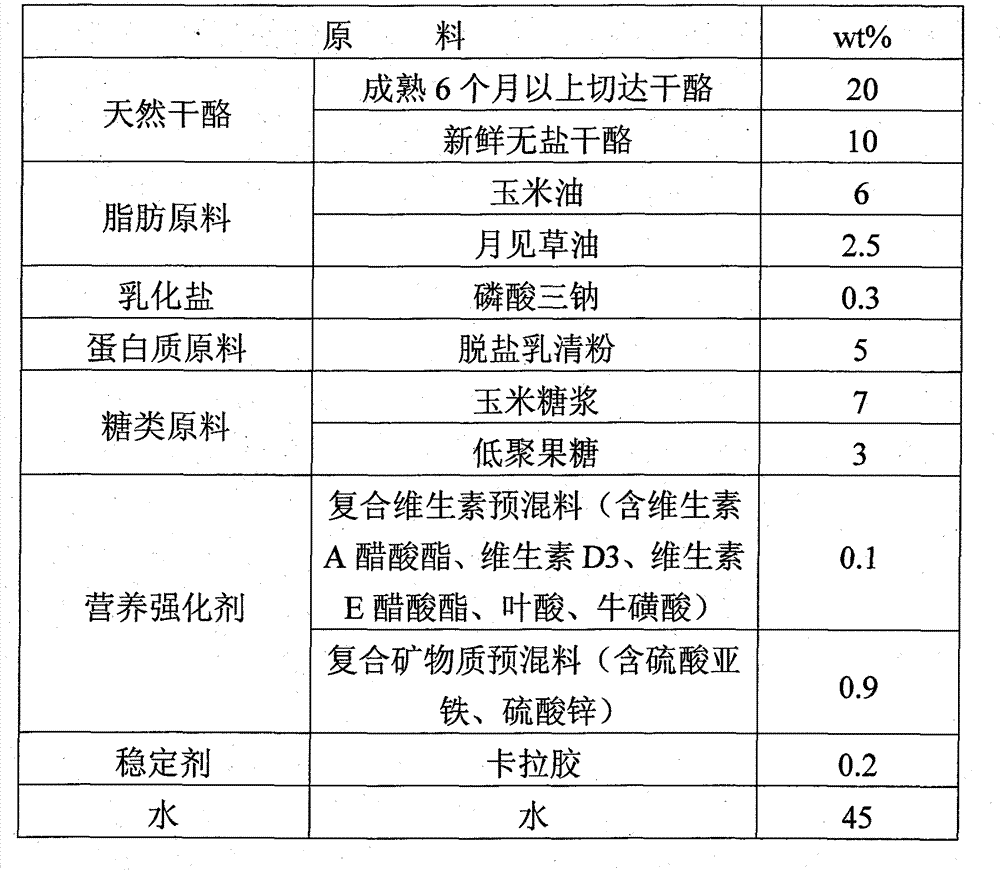

[0033] formula:

[0034]

[0035] Preparation Process:

[0036] ① Cut the natural cheese into pieces and mix with other ingredients and water, heat up to 85°C within 3.5 minutes and melt completely (vapor pressure 2.2bar); shear speed 1500rpm;

[0037] ②Homogeneous while hot, the homogeneous pressure is 15MPa;

[0038] ③The molten material is routinely sterilized by ultra-high temperature (137°C, 4s);

[0039] ④ Cool down to 85°C and stir for 10 minutes to emulsify;

[0040] ⑤ Aseptic filling, rapid cooling after packaging and molding, and the temperature of the product center drops below 25°C within 30 minutes to obtain the processed cheese smeared by infants of the present invention.

Embodiment 2

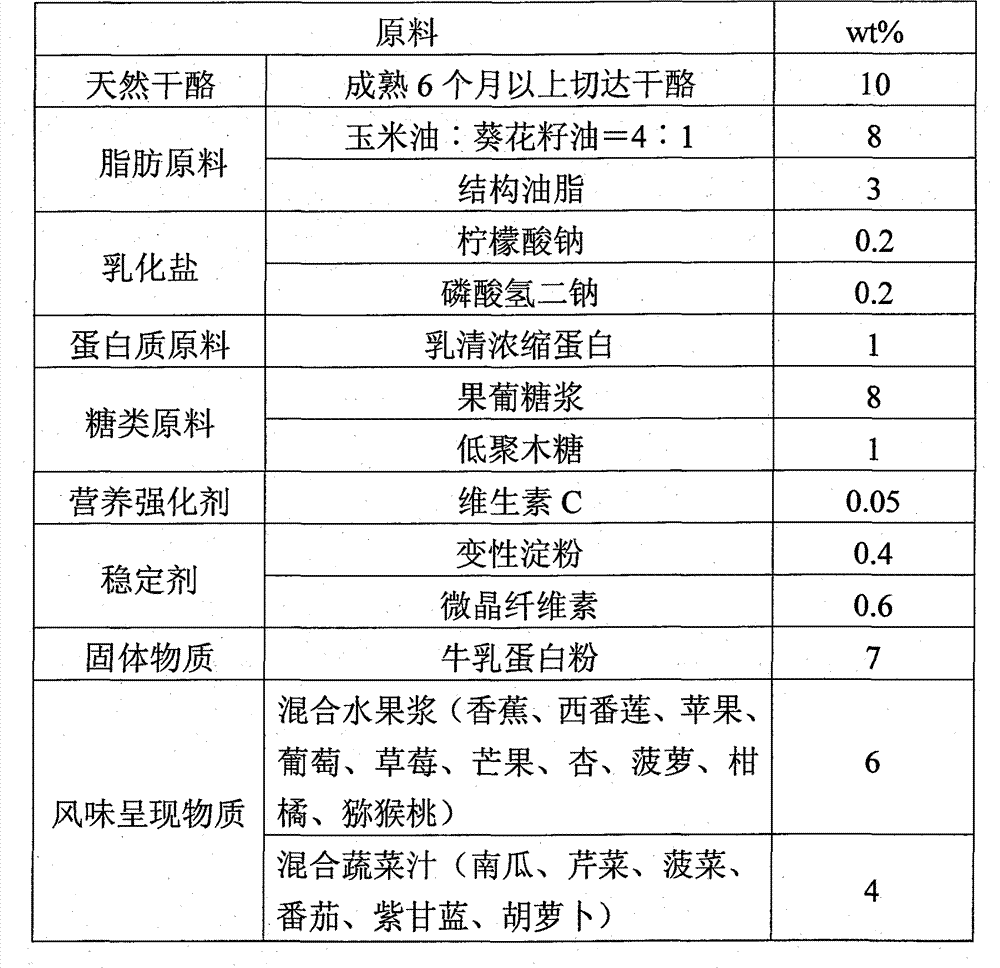

[0042] formula:

[0043]

[0044]

[0045] Preparation Process:

[0046] ① After the natural cheese is cut into pieces, stir and mix with other ingredients (except vitamin C) and water, and heat up to 95°C within 3.5 minutes to melt completely (vapor pressure 2.2bar); shear speed 1200rpm;

[0047] ②Homogeneous while hot, the homogeneous pressure is 12MPa;

[0048] ③The molten material is routinely sterilized by ultra-high temperature (140°C, 2s);

[0049] ④ Cool down to 80°C and stir for 5 minutes to emulsify;

[0050] ⑤ Add vitamin C after sterility and stir evenly.

[0051] ⑥ Aseptic filling, rapid cooling after packaging and molding, and the temperature of the center of the product drops below 25°C within 30 minutes to obtain the infant smeared processed cheese of the present invention.

Embodiment 3

[0053] formula:

[0054]

[0055]

[0056] Preparation Process:

[0057] ① After the natural cheese is cut into pieces, stir and mix with other ingredients (except vitamin premix) and water, and heat up to 90°C within 3.5 minutes to melt completely (vapor pressure 2.2bar); shear speed 1500rpm;

[0058] ②Homogeneous while hot, the homogeneous pressure is 15MPa;

[0059] ③The molten material is routinely sterilized by ultra-high temperature (135°C, 9s);

[0060] ④ Cool down to 80°C and stir for 10 minutes to emulsify;

[0061] ⑤ Add vitamin premix after aseptic, and stir evenly.

[0062] ⑥ Aseptic filling, rapid cooling after packaging and molding, and the temperature of the center of the product drops below 25°C within 30 minutes to obtain the infant smeared processed cheese of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com