Silicon rod self-centering synchronous clamping device

A synchronous clamping and self-centering technology, applied in the direction of working accessories, stone processing equipment, manufacturing tools, etc., can solve the problems of complex process, low cutting efficiency, low debugging efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

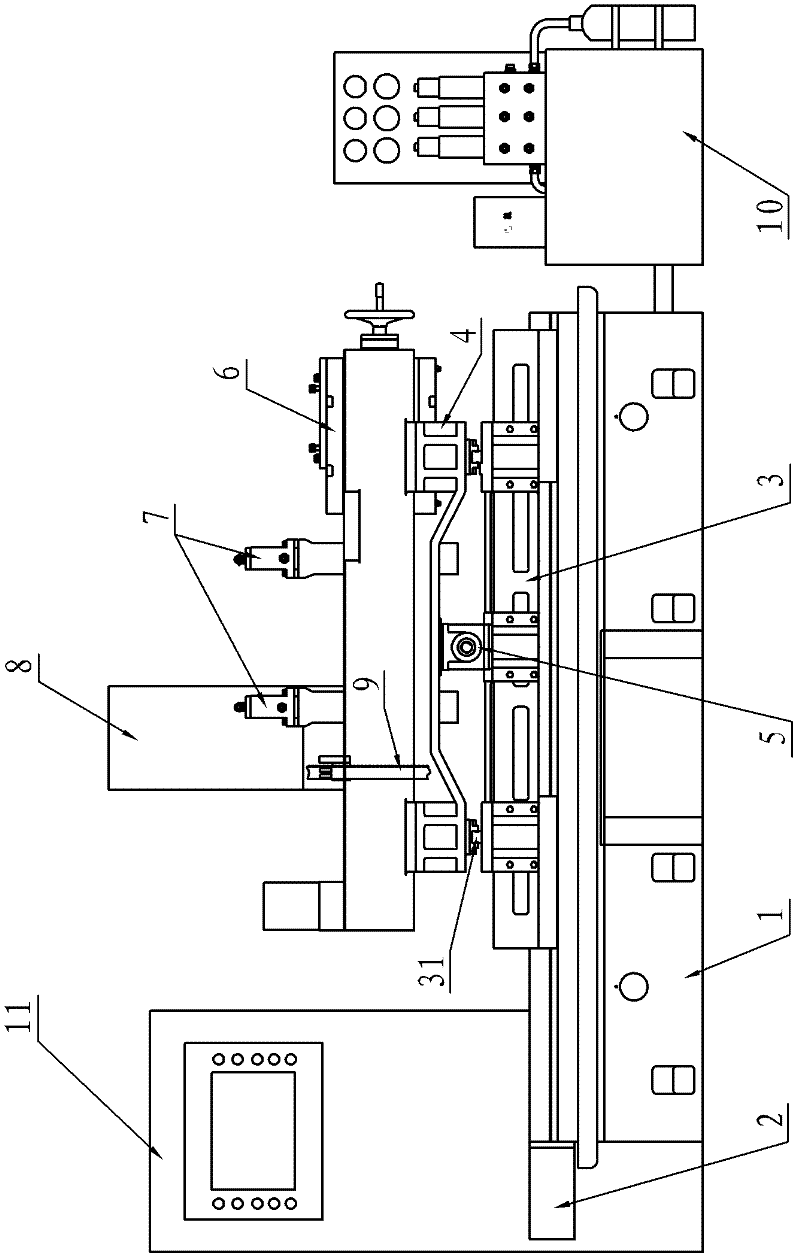

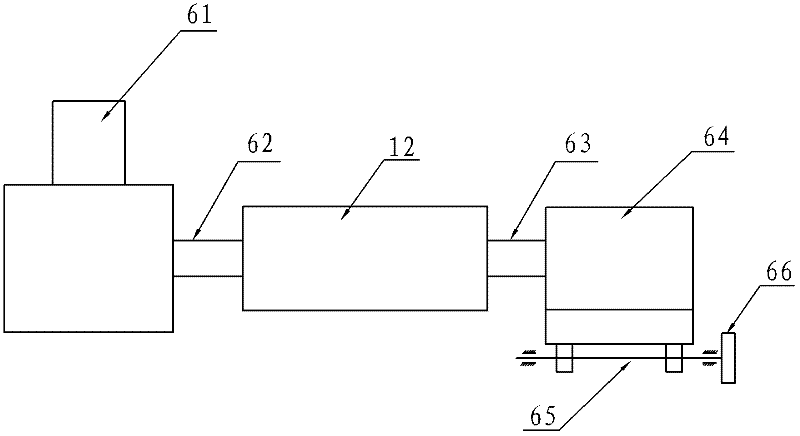

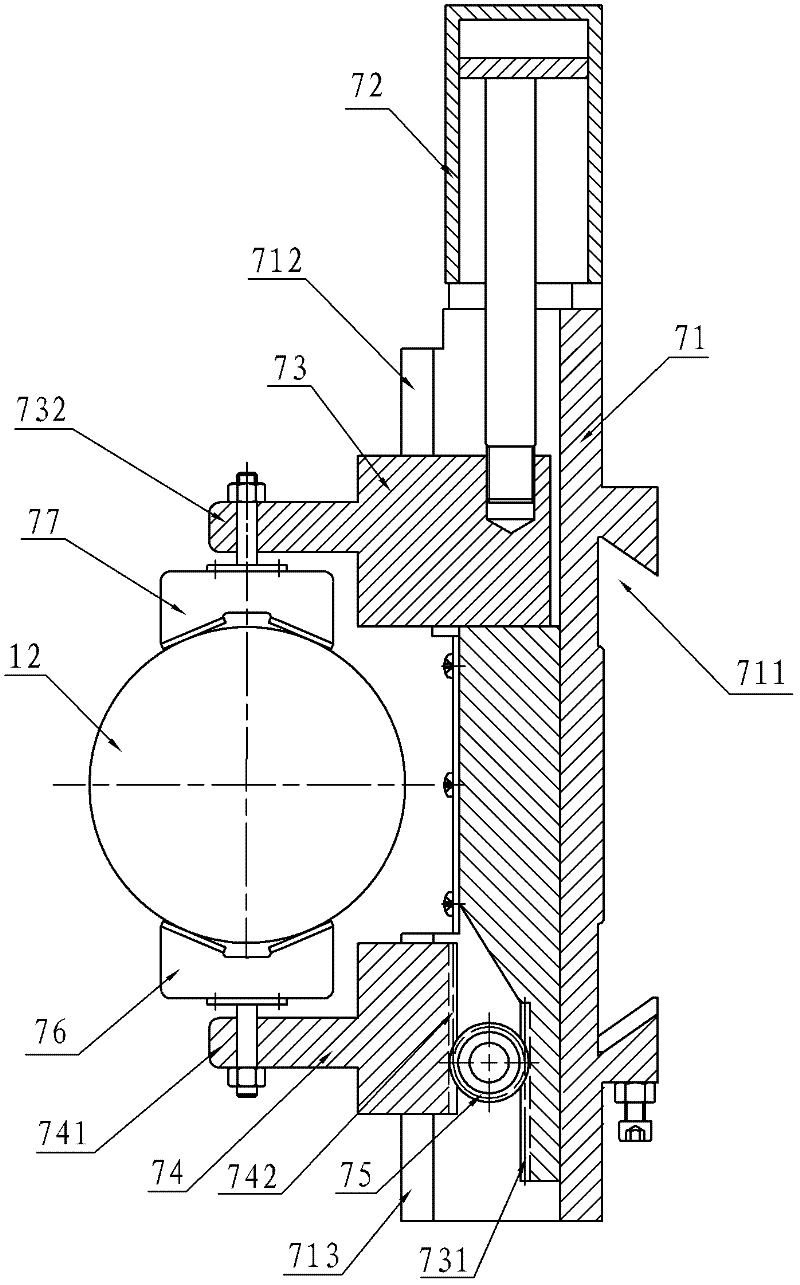

[0015] figure 1 It is a schematic structural view of the silicon rod cutting machine of the present invention, which includes a feed slide pedestal 1, a feed motor 2, a feed slide 3, a longitudinal feed slide 4, a longitudinal feed motor 5, a pressing device 6, Self-centering synchronous clamping device 7, band saw side stand 8, saw blade 9, hydraulic station 10 and electric control box 11, feed slide 3 is installed on feed slide base 1, feed slide 3 and feed A screw nut linear motion mechanism driven by the feed motor 2 is provided between the feed slide pedestal 1; a longitudinal slide rail 31 is provided on the feed slide 3, and the longitudinal feeding slide 4 and the feed slide 3 are vertically connected. The slide rail 31 is slidably matched, and a screw nut linear motion mechanism driven by the longitudinal feeding motor 5 is provided between the longitudinal feeding slide table 4 and the feed slide table 3; the top pressing device 6 is as figure 2 As shown, it includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com