Method for purifying urapidil by anti-solvent recrystallization method

An anti-solvent recrystallization and urapidil technology, applied in the direction of organic chemistry, can solve the problems of low yield and long crystallization time, and achieve the effect of high yield, rapid precipitation and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 5g of urapidil (purity 96.16%) to 15ml of dichloromethane, heat it at 40°C to dissolve it, filter it while hot, and add the filtrate to the anti-solvent 30ml of ethyl formate at 5ml / min, and quickly When white turbidity appeared, it was left to stand for 0.5 h, filtered under reduced pressure, and the obtained solid was dried under vacuum at room temperature to obtain 4.87 g of urapidil with a yield of 97.4% and a purity of 99.98%.

[0020] The purity of the product was detected by Shimadzu LC-10ATvp high performance liquid chromatograph (SPD-10ATvp detector).

[0021] Detection method: National standard for new drug conversion [WS1-(X-116)-2003Z].

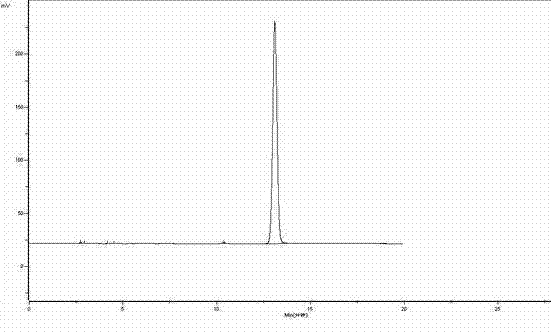

[0022] attached figure 1 The results of HPLC analysis of urapidil standard are as follows:

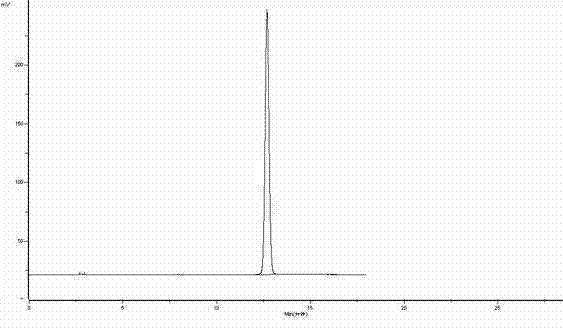

[0023] attached figure 2 The HPLC analysis results of Urapidil before the anti-solvent recrystallization of Experimental Example 1 are as follows:

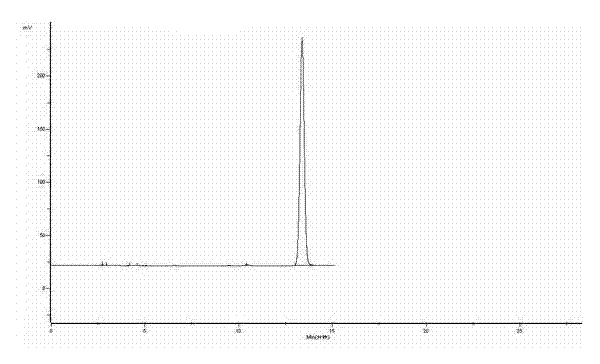

[0024] attached image 3 The HPLC analysis results of Urapidil aft...

Embodiment 2

[0027] Add 5g of urapidil (purity 96.16%) to 15ml of DMSO, heat it at 45°C to dissolve it, filter it while hot, and the obtained filtrate is added to 50ml of petroleum ether at a rate of 10ml / min, and white turbidity quickly appears. Set for 0.5 h, filter under reduced pressure, and vacuum dry the obtained solid at room temperature to obtain 4.79 g of urapidil with a yield of 95.8% and a purity of 99.98%.

Embodiment 3

[0029] 5g of urapidil (purity 96.16%) was added to 15ml of THF, heated at 45°C to dissolve it, filtered while hot, and the obtained filtrate was added to the anti-solvent 30ml of ethyl acetate and 10ml of petroleum ether at a rate of 15ml / min, White turbidity quickly appeared, left standing for 0.5 h, filtered under reduced pressure, and the obtained solid was vacuum-dried at room temperature to obtain 4.67 g of urapidil with a yield of 93.4% and a purity of 99.93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com